6.

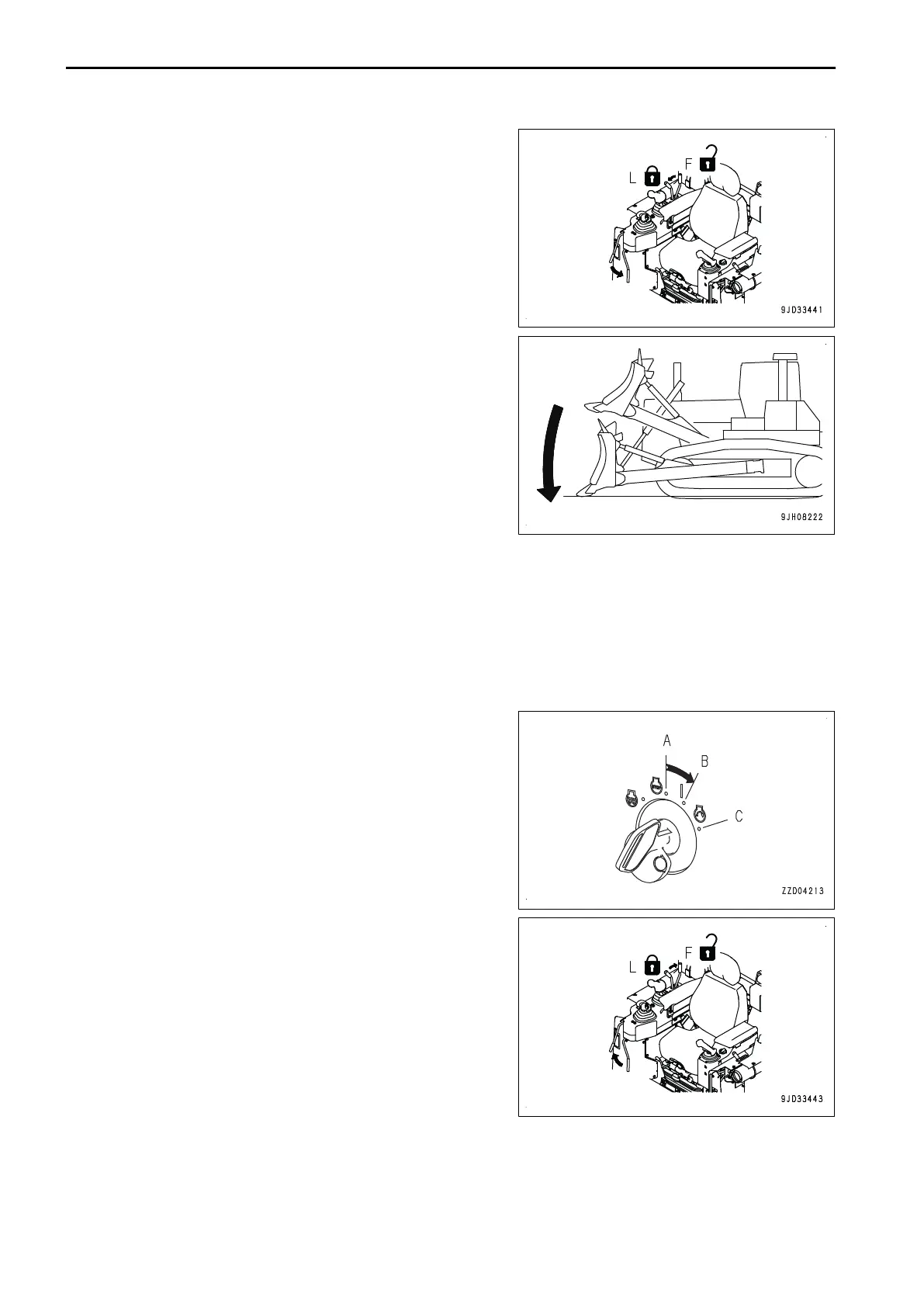

Set

the work equipment lock lever to FREE position (F),

and move the blade control lever in LOWER direction full

stroke.

7.

Check that the work equipment lowers to the ground.

If the work equipment goes down under its weight and contacts the ground, the accumulator is normal.

If

the work equipment does not go down or stops in midway, the charged pressure of the gas in the accumulator

for the hydraulic circuit has probably dropped.

Ask your Komatsu distributor for inspection.

After completion of the inspection, set the work equipment lock lever to LOCK position and turn the starting

switch to OFF position.

METHOD FOR RELEASING PRESSURE IN HYDRAULIC CIRCUIT

1.

Lower the work equipment to the ground.

2.

Set the parking brake lever and work equipment lock lever

to LOCK positions.

3.

Stop the engine.

4.

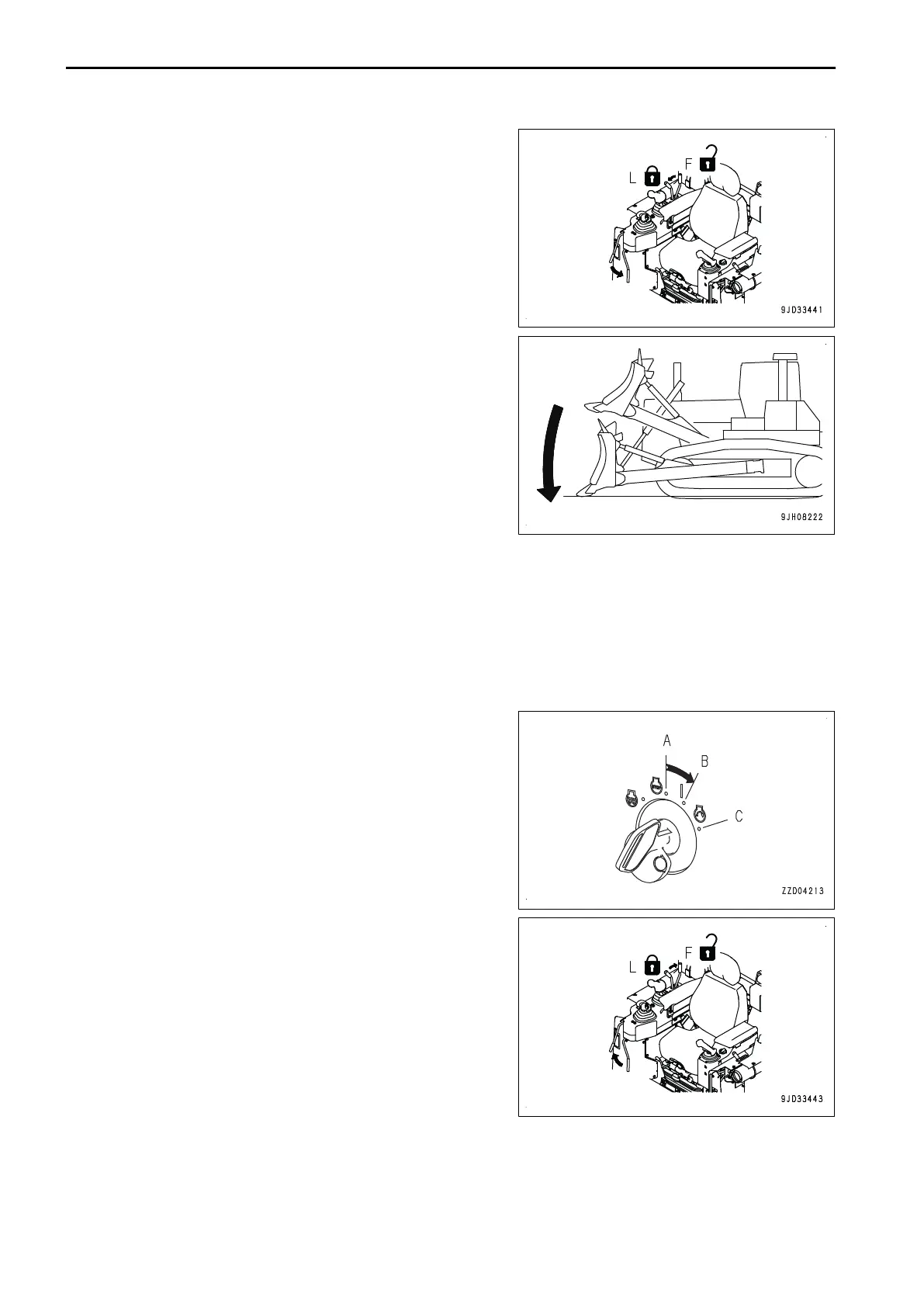

Turn the starting switch to ON position (B).

5.

Set the work equipment lock lever to FREE position (F).

6.

Operate the blade control lever and ripper control lever

fully

to the front, rear, left, and right to release the pressure

from the hydraulic circuits.

7.

Set the work equipment lock lever to LOCK position, then

turn the starting switch to OFF position (A).

METHOD FOR CHECKING ALTERNATOR

Remove the belt and check that the alternator can rotate smoothly without the belt.

MAINTENANCE PROCEDURE MAINTENANCE

4-74

Loading...

Loading...