• Do not perform sampling on rainy or windy days when water or dust can get into the oil.

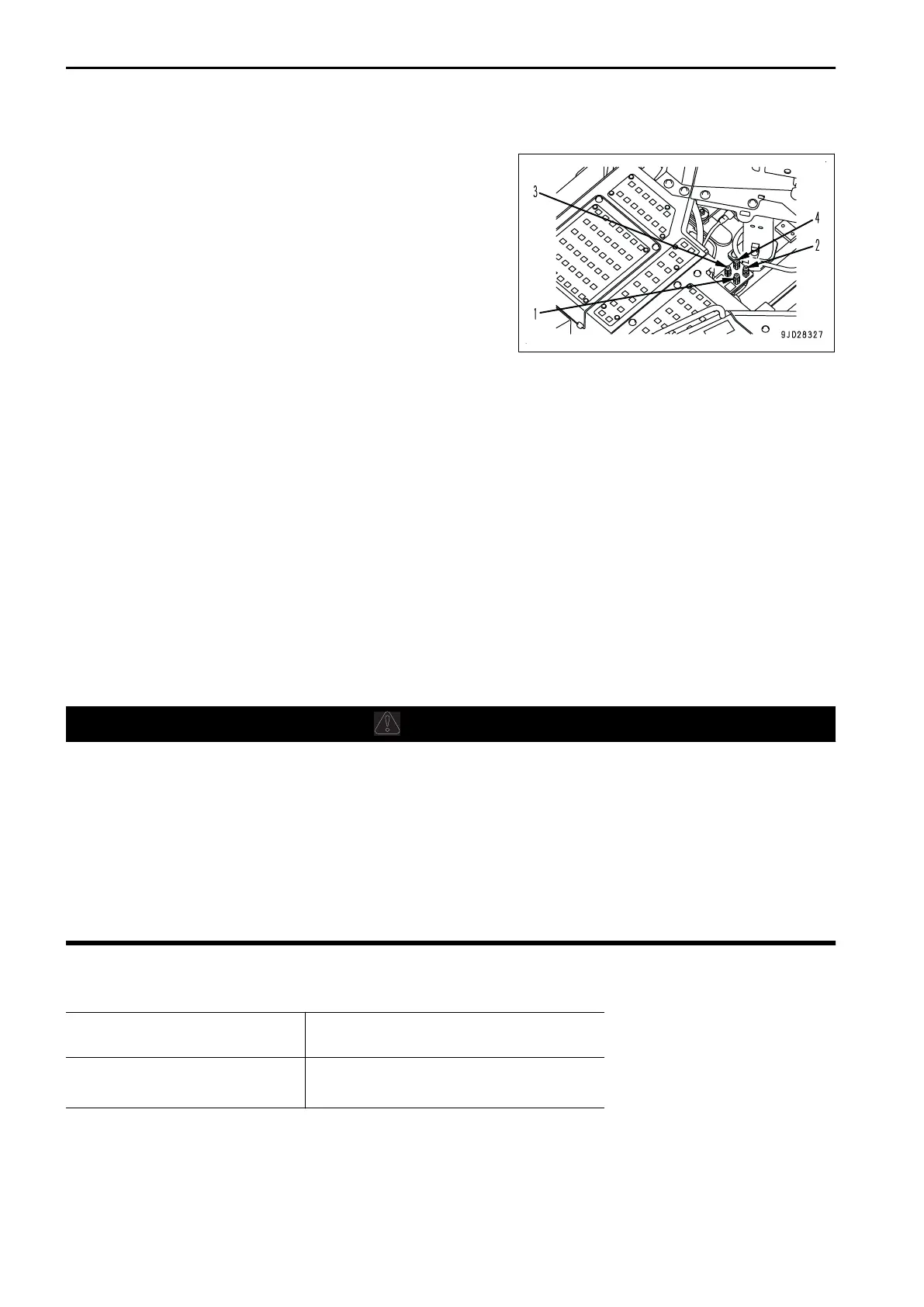

(1): Coolant

(2): Engine oil

(3): Hydraulic oil

(4): Power train oil

T

est port : Part No.799-101-5220

Mounting screw : Size: M10 x 1.25 (SAE O-ring boss)

Precautions when sampling

• Stop the engine before connecting sampling coupler.

• Run the engine at low idling when sampling.

• Park the machine before performing sampling.

(Parking brake ON, work equipment lock lever ON, steering lock lever ON)

• The sampled oil is at high temperature, so be careful not to burn yourself.

• Oil inside the hose contains remained oil from last sampling. If you start sampling as it is, it may cause the

error. When sampling, do not collect the oil into the bottle as it is, pour some amount of oil into another

bottle, and then collect the oil into the bottle.

• Immediately after the engine is started, the wear powder precipitates in the oil and the oil density may be

low so that the signs of error may not be found. Start the engine before collecting the oil.

For further details of KOWA, contact your Komatsu distributor.

WHEN REQUIRED

METHOD FOR CLEANING INSIDE OF COOLING SYSTEM

WARNING

• Immediately

after the engine is stopped, the coolant is still hot and the pressure is accumulated in

the radiator. If the cap is removed under this condition and the coolant is drained, it may cause

burn. Always wait for the temperature to go down, and turn the cap slowly to release the pressure.

• Start the engine and clean the inside of the cooling system. When standing up or leaving the opera-

tor's seat, lock the parking brake lever and work equipment lock lever.

• Never approach the fan at the front of the machine while the engine is running. There is a danger of

touching the fan.

• It is very dangerous to go under the machine for cleaning while the engine is running, since the ma-

chine may move unexpectedly. While the engine is running, never go under the machine.

Place the machine on a level ground when cleaning or changing the coolant.

Clean the inside of the cooling system, change the coolant according to the table.

Coolant

Cleaning of inside of cooling system and re-

placement of coolant

Non-Amine Engine Coolant

(AF-NAC)

Every 2 years or

4000 hours, whichever comes sooner

The coolant has the important function of preventing corrosion as well as preventing freezing.

Even in the areas where freezing is not an issue, the use of coolant is essential.

MACHINE WITH MINING SPECIFICATION ATTACHMENTS AND OPTIONS

6-32

Loading...

Loading...