METHOD FOR CHANGING COOLANT, CHECKING AND REPLACING RADIATOR

CAP AND PRESSURE CAP

WARNING

• Immediately

after the engine is stopped, the coolant is still hot and the pressure is accumulated in

the radiator. You may get burn injury if you remove the cap in this state. Always wait for the temper-

ature to go down, turn the cap slowly to release the pressure, then remove the cap with care.

• When starting the engine while cleaning the machine, set the parking brake lever and the work

equipment lock lever in LOCK position to prevent the machine from moving.

• For the detail of starting the engine, see OPERATION section.

• When the undercover is removed, there is a danger of touching the fan.

Never enter the rear part of the machine when the engine is running.

NOTICE

If

the seal portion of radiator cap and pressure cap is dirty or deteriorated or damaged, the coolant may

not return from the reservoir tank to the radiator, and may cause the machine failure.

Place the machine on a level ground when cleaning the inside of cooling system or changing the coolant.

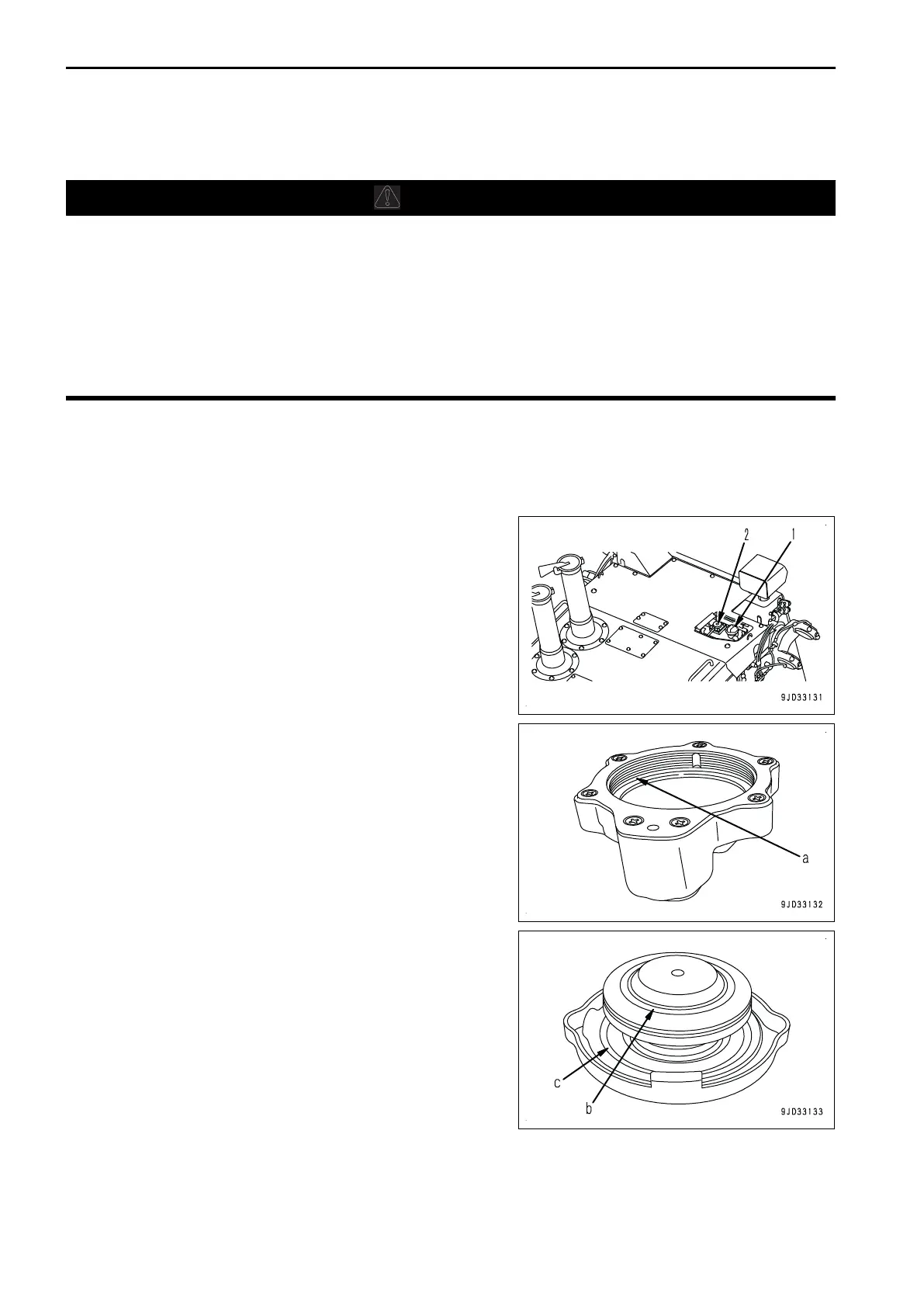

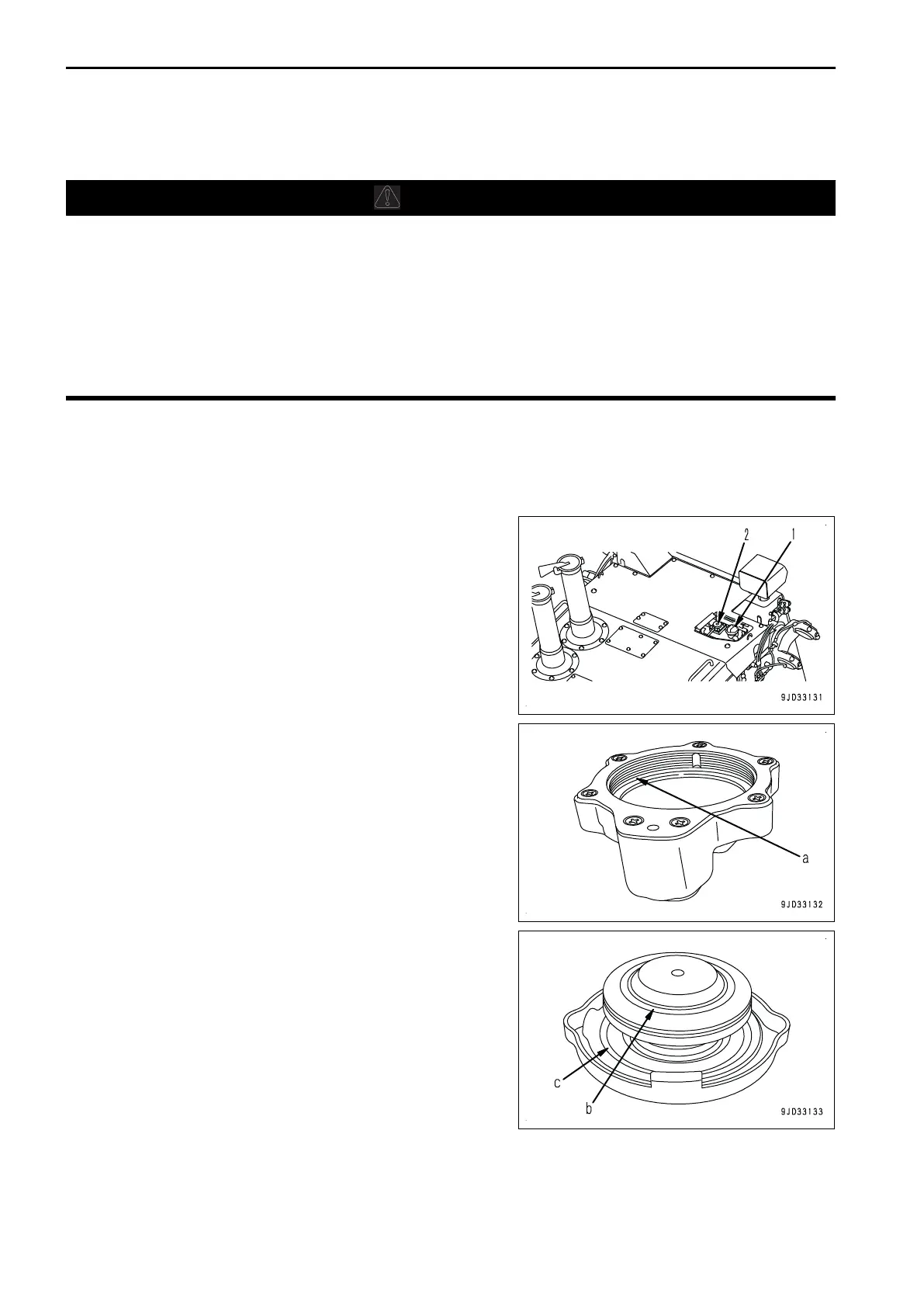

1.

Check that the seal (a) of the radiator cap (1) is not de-

formed

nor cracked, and the foreign material such as the

sand is not stuck.

If there is an abnormality, clean or replace the seal.

2.

Check that the seals (b) and (c) of the pressure cap (2) are

not deformed nor cracked, and the foreign material such

as the sand is not stuck.

If there is an abnormality, clean or replace the seal.

If the foreign material is stuck, the coolant may be mixed with a plenty of foreign materials. Clean it according to

“METHOD FOR CLEANING INSIDE OF COOLING SYSTEM”.

MAINTENANCE PROCEDURE MAINTENANCE

4-82

Loading...

Loading...