METHOD FOR USING FUEL, COOLANT AND LUBRICANTS ACCORDING

T

O AMBIENT TEMPERATURE

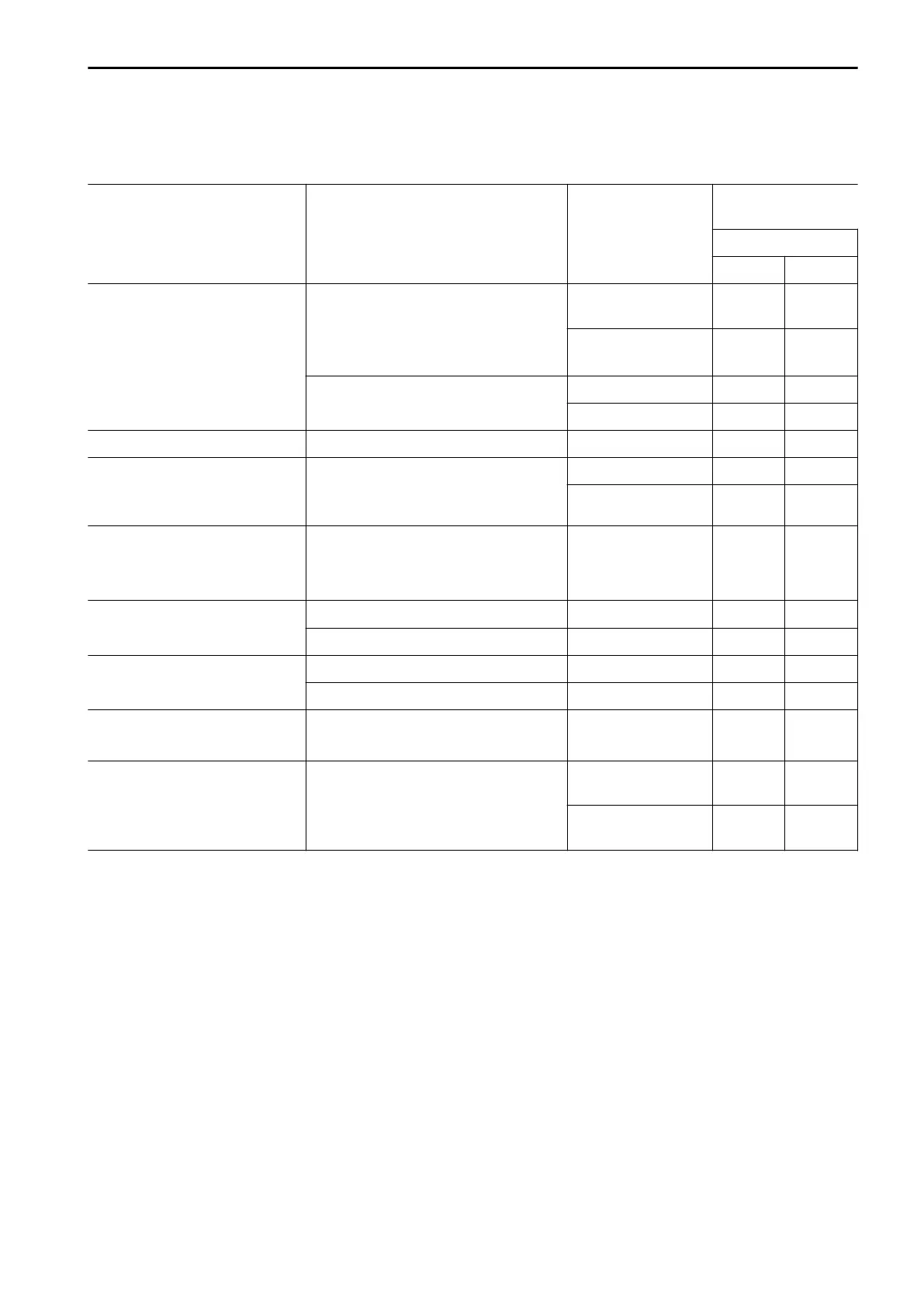

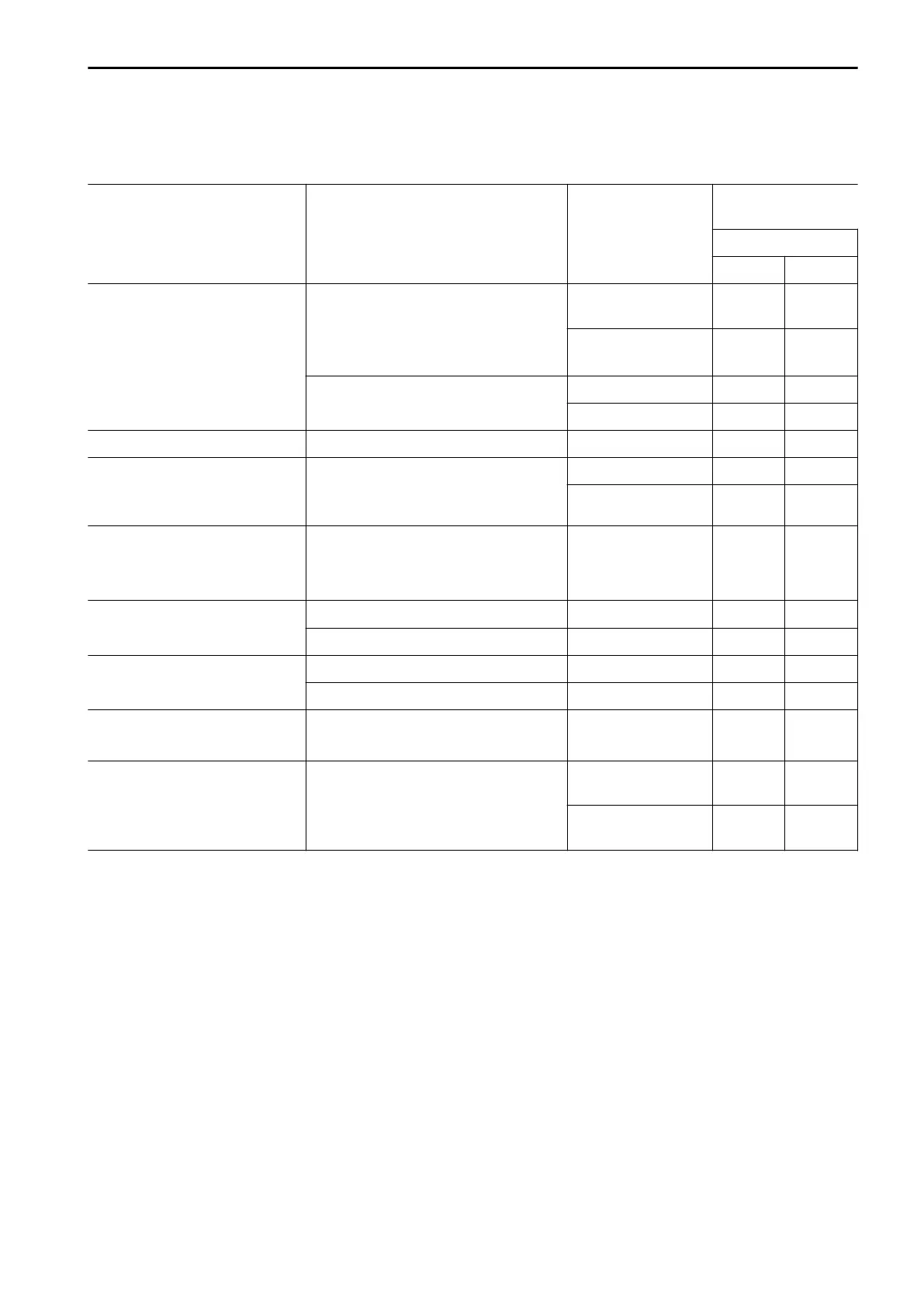

Reservoir Fluid type

Recommended Ko-

matsu Fluids

Ambient tempera-

ture

°C

Min Max

Engine oil pan

Engine oil for KDPF used in cold ter-

rain

(Oil Change interval 250 hours)

(Note.1)

EOS5W30-LA

(KES)

-25 35

EOS5W40-LA

(KES)

-25 40

Engine oil for KDPF

(Oil Change interval 500 hours)

EO10W30-LA (KES) -20 40

EO15W40-LA (KES) -15 50

Damper case Power train oil TO30 (KES) -30 50

Power train case

(incl. T

ransmission, torque con-

verter, bevel gear case)

Power train oil

TO10 (KES) -30 10

TO30 (KES) 0 50

Final drive case (each)

Pivot bearing (each)

Recoil spring (each)

Power train oil TO30 (KES) -30 50

Hydraulic System

Power train oil TO10 (KES) -20 50

Hydraulic Oil HO46-HM (KES) -20 50

Grease fitting

Hyper grease (Note.2) G2-TE (KES) -20 50

Lithium EP grease G2-LI (KES) -10 50

Cooling system

Non-Amine Engine Coolant

AF-NAC (Note.3)

AF-NAC (KES) -30 50

Fuel tank Diesel fuel

ASTM D975 No.1–D

S15

-40 20

ASTM D975 No.2–D

S15

0 50

KES: Komatsu Engineering Standard

ASTM: American Society of T

esting and Material

REPLACEMENT PARTS RECOMMENDED FUEL, COOLANT, AND LUBRICANT

7-7

Loading...

Loading...