EFFECTIVE USE OF RIPPER

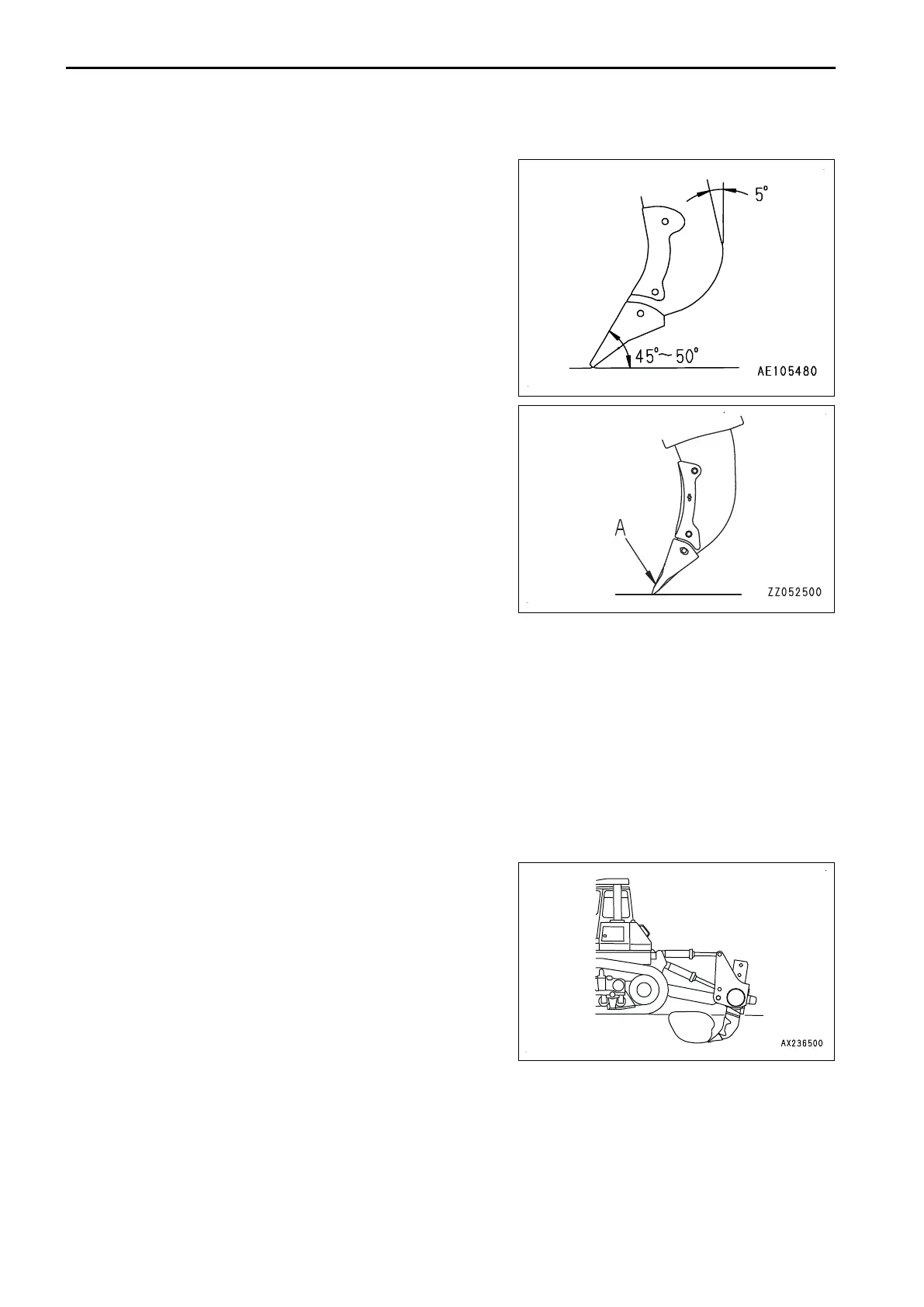

• The optimum digging angle for the shank is when the

shank is tilted back for approximately 5

° to the ground (rip-

ping angle: 45 to 50 °).

• The ripper can dig rocks even if the shank is tilted out (rip-

per point tip angle is large), if they are relatively soft (elas-

tic wave 1500 m/s or less).

• If

the ripper digs relatively hard rocks with the shank tilted

out, ripper point tip (A) is worn uselessly and its cutting

performance is deteriorated.

• During ripping operations, if the shoes slip because of

boulders or resistance from the bedrock, use the tilt cylin-

der.

When picking up a stone, advance the machine at a fixed

gear speed (F1 or F2).

REMARK

• When raising boulders or digging up rockbed, do not put

the transmission in neutral. If the transmission is in neutral,

the reaction of the tilt cylinder will push the machine back.

Always operate the machine with the transmission in FOR-

WARD.

• Choosing a suitable ripper point to match the type of rock

is one of the most important elements in using the ripper

effectively.

Ripper points are available for different types of rock, so

select the most suitable ripper point from the list. For de-

tails, see “SELECTION PROCEDURE OF RIPPER

POINT”.

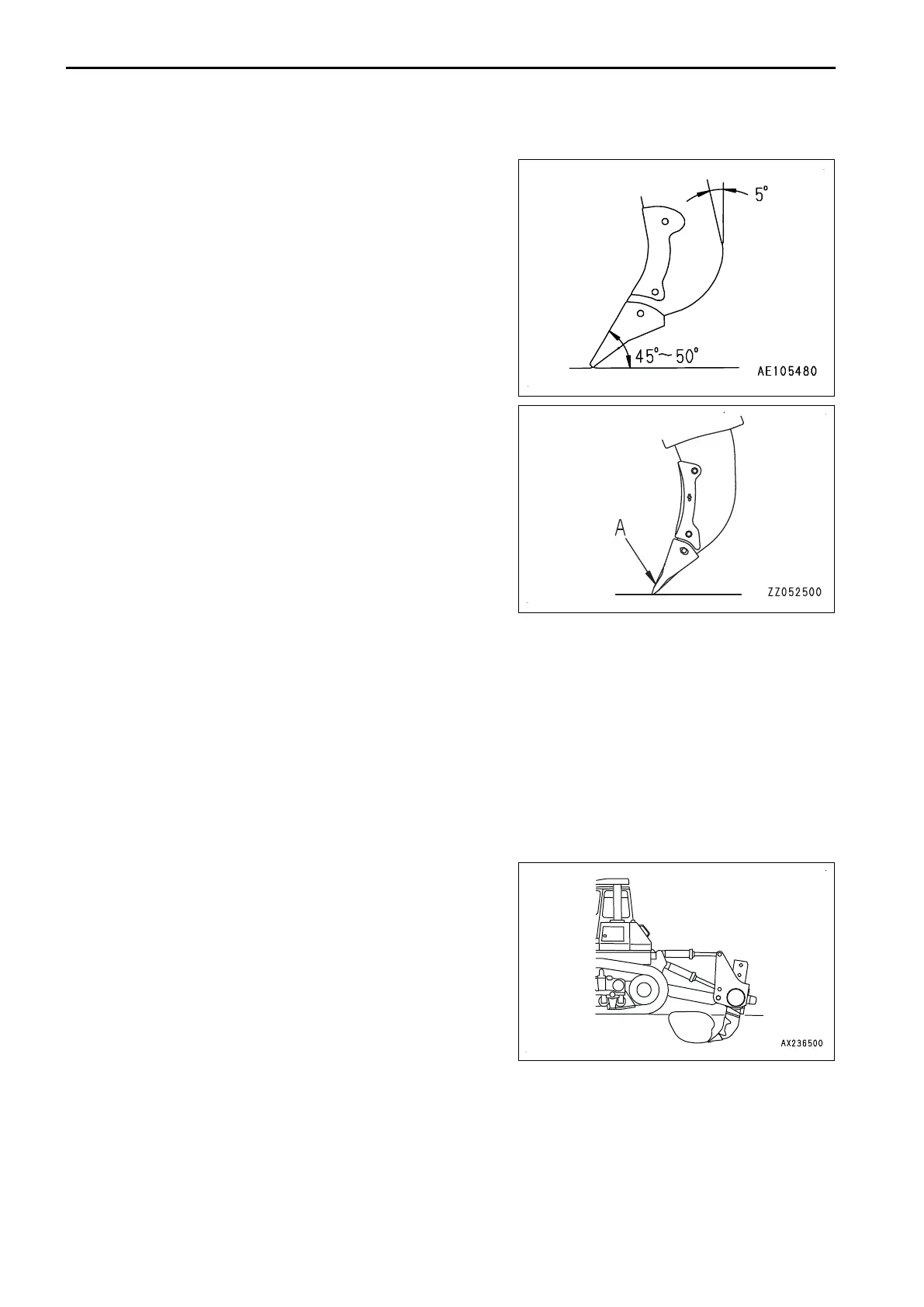

WORK OF DIGGING UP LARGE BOULDERS AND ROCK-BED

While working with a variable ripper, if the track shoe slips or

the travel speed decreases on large boulders or a hard rock-

bed, use the tilt cylinder to dig up the large boulders and rock-

bed.

OPERATE ON SLOPE

When a variable ripper is used, select the dimension L by adjusting the length of the tilt cylinder.

MACHINE OPERATIONS AND CONTROLS OPERATION

3-196

Loading...

Loading...