2.

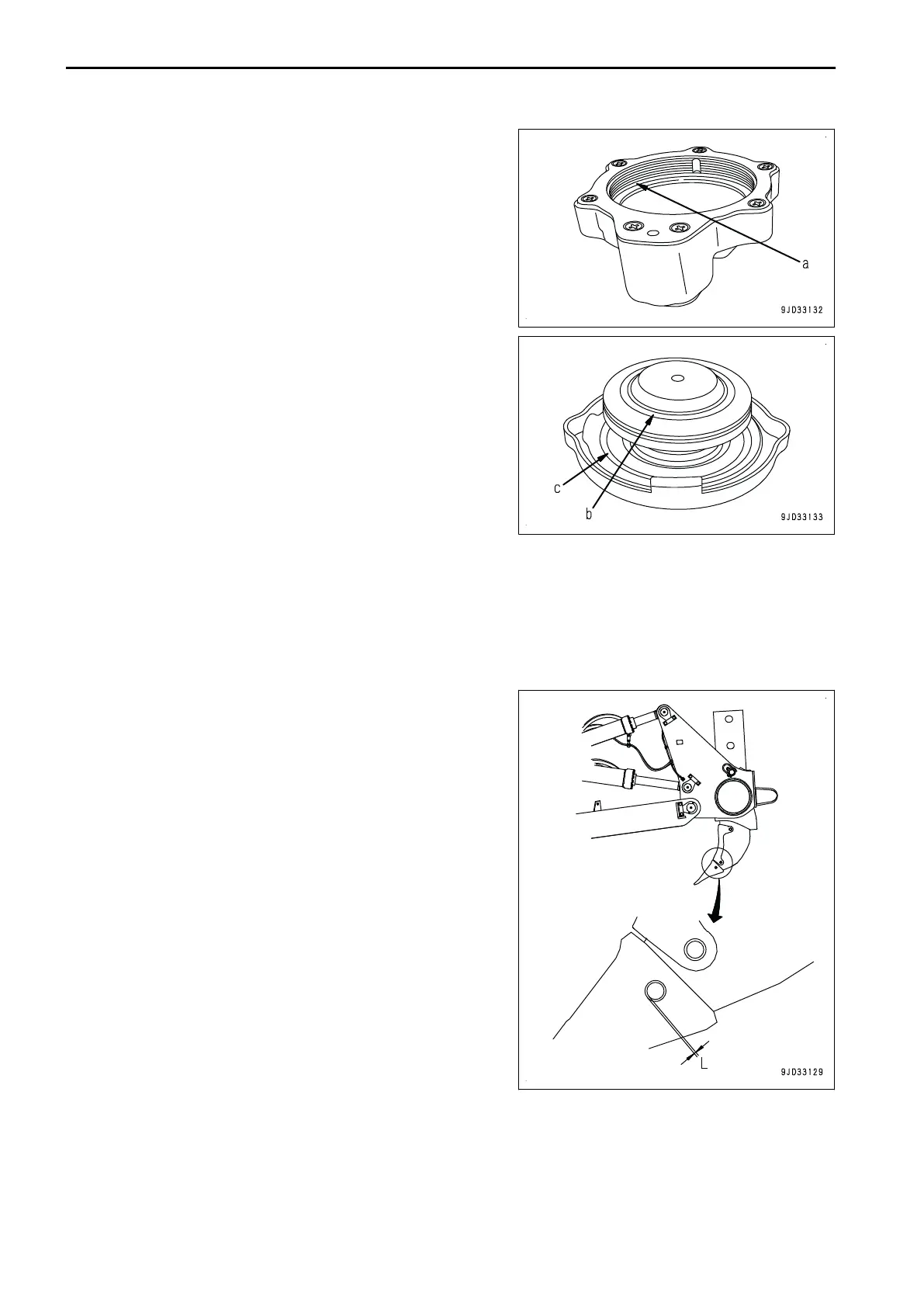

Check

that the seals (b) and (c) of the pressure cap (2) are

not deformed nor cracked, and the foreign material such

as the sand is not stuck.

If there is an abnormality, clean or replace the seal.

If the foreign material is stuck, the coolant may be mixed with a significant amount of foreign material. Clean it

according to “METHOD FOR CLEANING INSIDE OF COOLING SYSTEM”.

METHOD FOR CHECKING AND REPLACING RIPPER SHANK

NOTICE

If the wear of the contact face with inside of ripper point at the tip of the ripper shank advances, the

point fixing pin may break due to the load on the ripper point.

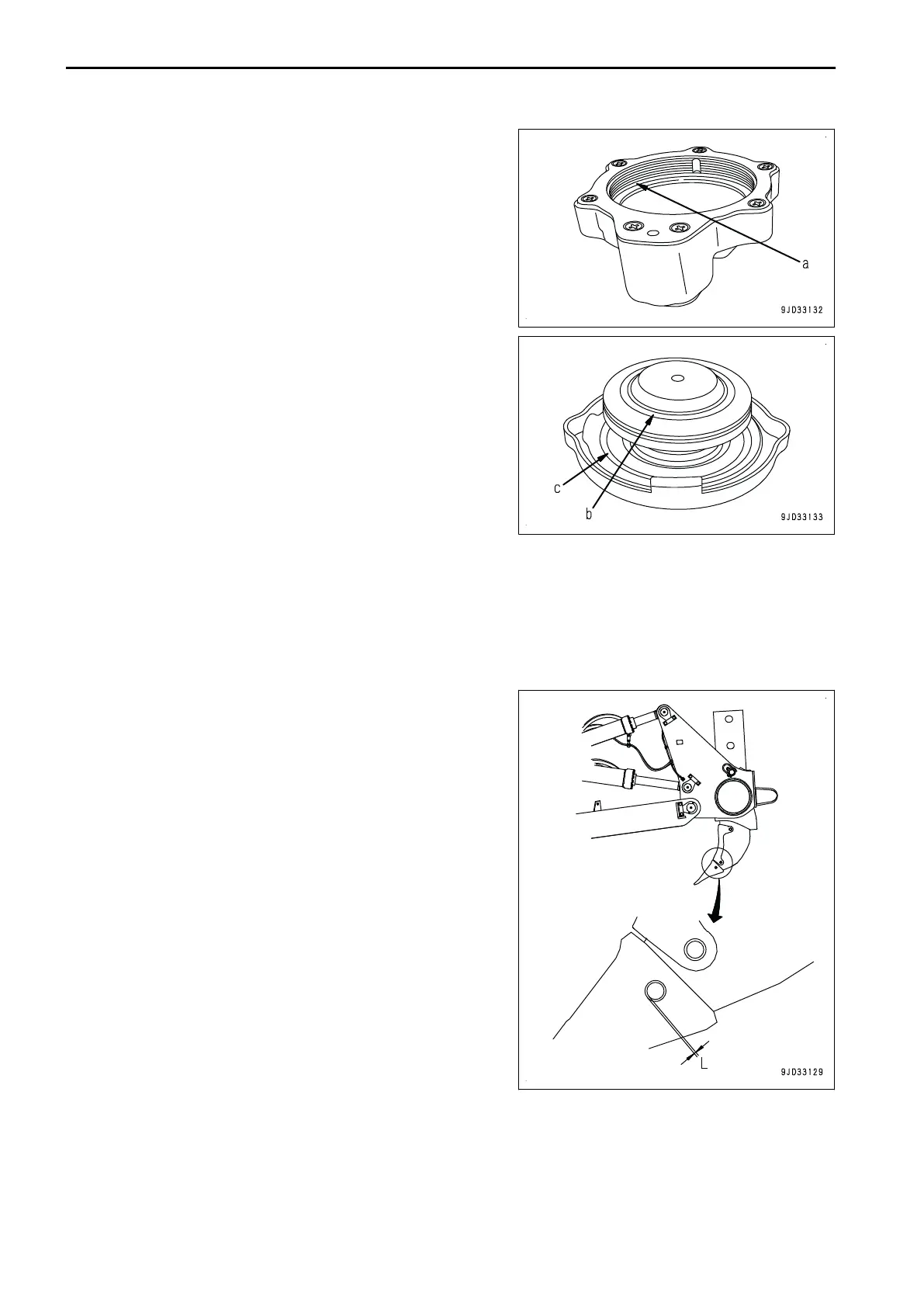

1.

Lower the tip of the ripper shank to the ground, and meas-

ure

the minimum clearance (L) between the ripper point

and the point fixing pin.

2.

If the minimum clearance (L) is 0 mm and the ripper point

contacts the point fixing pin, replace the ripper shank.

Ask your Komatsu distributor for replacement of the ripper

shank.

REMARK

When assembling the new ripper shank and the ripper

point, default value of the clearance is 3.1

mm.

CHECKS BEFORE STARTING

For the following items, see OPERA

TION, “METHOD FOR CHECKING BEFORE STARTING”.

• METHOD FOR DRAINING WATER AND SEDIMENT FROM FUEL TANK

• METHOD FOR CHECKING WATER SEPARATOR, DRAINING WATER AND SEDIMENT

• METHOD FOR CHECKING OIL LEVEL IN HYDRAULIC TANK, ADDING OIL

MAINTENANCE PROCEDURE MAINTENANCE

4-46

Loading...

Loading...