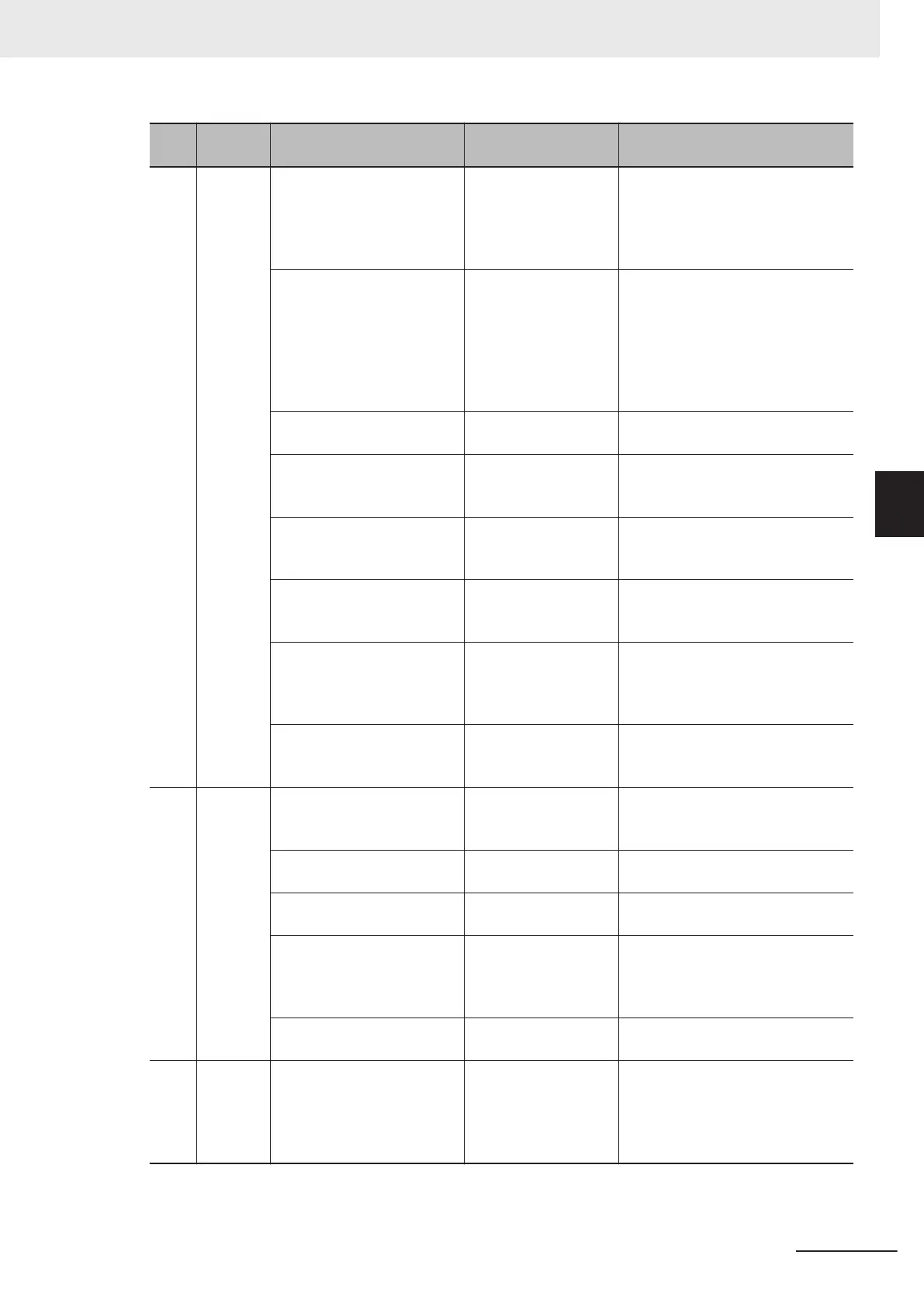

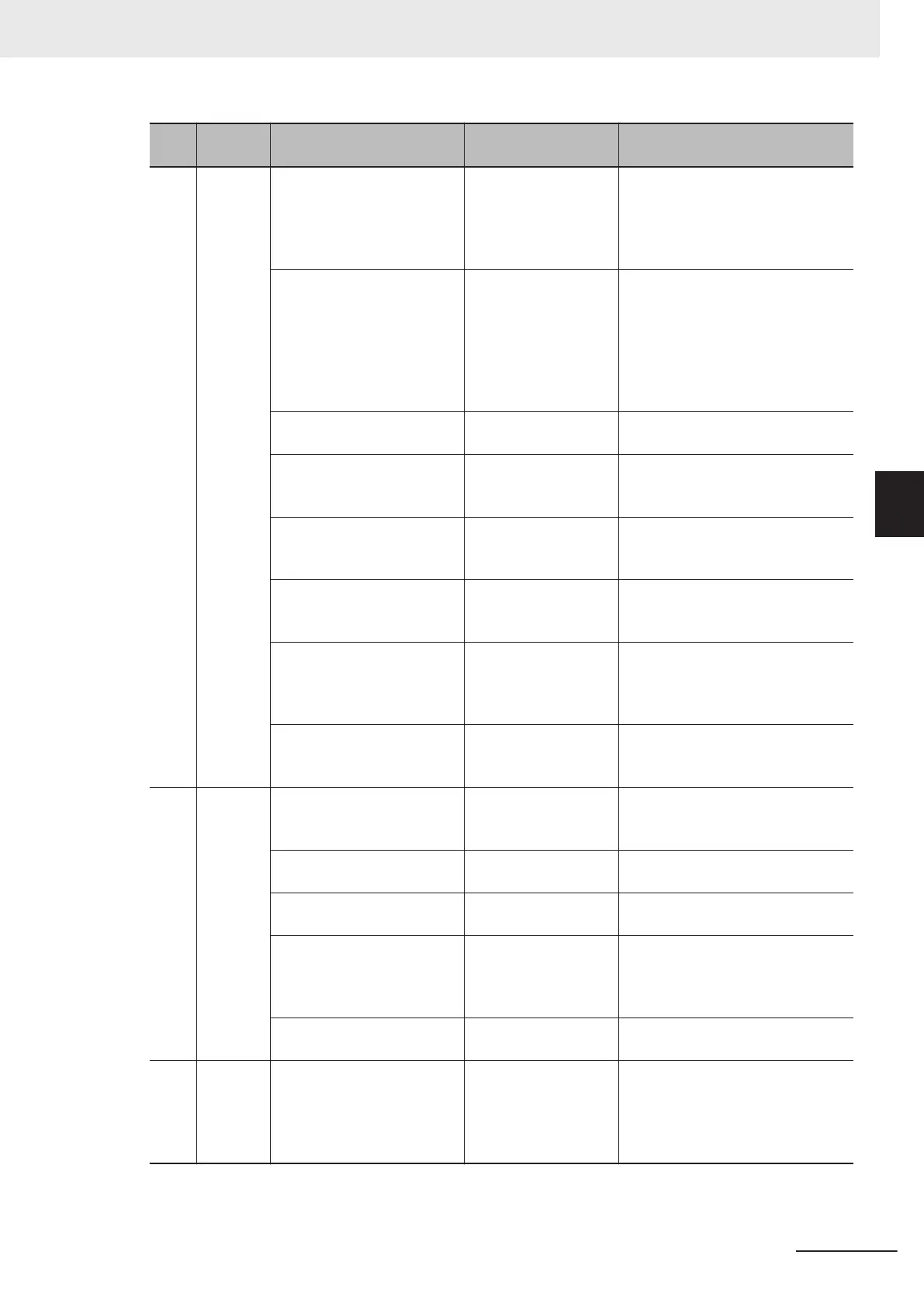

No.

Inspec-

tion item

Inspection details Criteria Correction

3 Ambient

environ-

ment

Is the ambient operating

temperature within stand-

ards?

0 to 55°C Use a thermometer to check the

temperature and ensure that the

ambient operating temperature re-

mains within the allowed range of 0

to 55°C.

Is the ambient operating hu-

midity within standards?

Relative humidity must

be 10% to 95%

with no condensation.

Use a hygrometer to check the hu-

midity and ensure that the ambient

operating humidity remains be-

tween 10% and 95%.

Make sure that condensation does

not occur due to rapid changes in

temperature.

Is it subject to direct sun-

light?

Not in direct sunlight Protect the Controller if necessary.

Is there an accumulation of

dirt, dust, salt, metal powder

,

etc.?

No accumulation

Clean and protect the Controller if

necessary.

Is there water, oil, or chemi-

cal sprays hitting the Control-

ler?

No spray Clean and protect the Controller if

necessary.

Are there corrosive or flam-

mable gases in the area of

the Controller?

No spray Check by smell or use a sensor

.

Is the Unit subject to shock

or vibration?

Vibration resistance

and shock resistance

must be within specifi-

cations.

Install cushioning or other vibration

and shock absorbing equipment if

necessary.

Are there noise sources near

the Controller?

No significant noise

sources

Either separate the Controller and

noise source or protect the Control-

ler.

4

Installa-

tion and

wiring

Are the DIN track mounting

hooks for each NX Unit se-

curely locked?

No looseness Securely lock the DIN track mount-

ing hooks.

Are the cable connectors

fully inserted and locked?

No looseness Correct any improperly installed

connectors.

Are there any loose screws

on the End Plates (PFP-M)?

No looseness Tighten loose screws with a Phil-

lips-head screwdriver

.

Are the NX Units connected

to each other along the

hookup guides and until they

touch the DIN track?

Y

ou must connect and

fix the NX Units to the

DIN track.

Connect the NX Units to each other

along the hookup guides and until

they touch the DIN track.

Are there any damaged ex-

ternal wiring cables?

No visible damage Check visually and replace cables if

necessary.

5

Safety

validation

testing

(user

testing)

Check to be sure that all

safety functions operate cor-

rectly.

All functions must op-

erate as intended.

Remove the cause of errors and

check the operation of all safety

functions again.

13 Inspection and Maintenance

13 - 3

NX-series Safety Control Unit User's Manual (Z930)

13-1 Cleaning and Inspection

13

13-1-2 Periodic Inspections

Loading...

Loading...