7 Programming

7 - 12

NX-series Safety Control Unit User’s Manual (Z930)

7-2 Variables

In the Safety CPU Unit, variables are used to exchange I/O information with external devices, to per-

form data calculations, and to perform other processes.

This section describes variable designations in detail.

Variables store I/O data for exchange with external devices or temporary data that is used for internal

POU processing. A variable has attributes, such as a name and data type.

You do not need to assign a memory address to a variable. The Sysmac Studio automatically allocates

memory addresses in the memory area for variables.

Variables are broadly classified into the following two types.

User-defined Variables

The user defines all of the attributes of a user-defined variable. The rest of this section describes

user-defined variables.

Semi-user-defined Variables

For semi-user-defined variables, some attributes are designed by the system, while others are

defined by the user. This includes variables that are used to access specific devices and data. This

is the equivalent of a device variable in the Safety Control Unit.

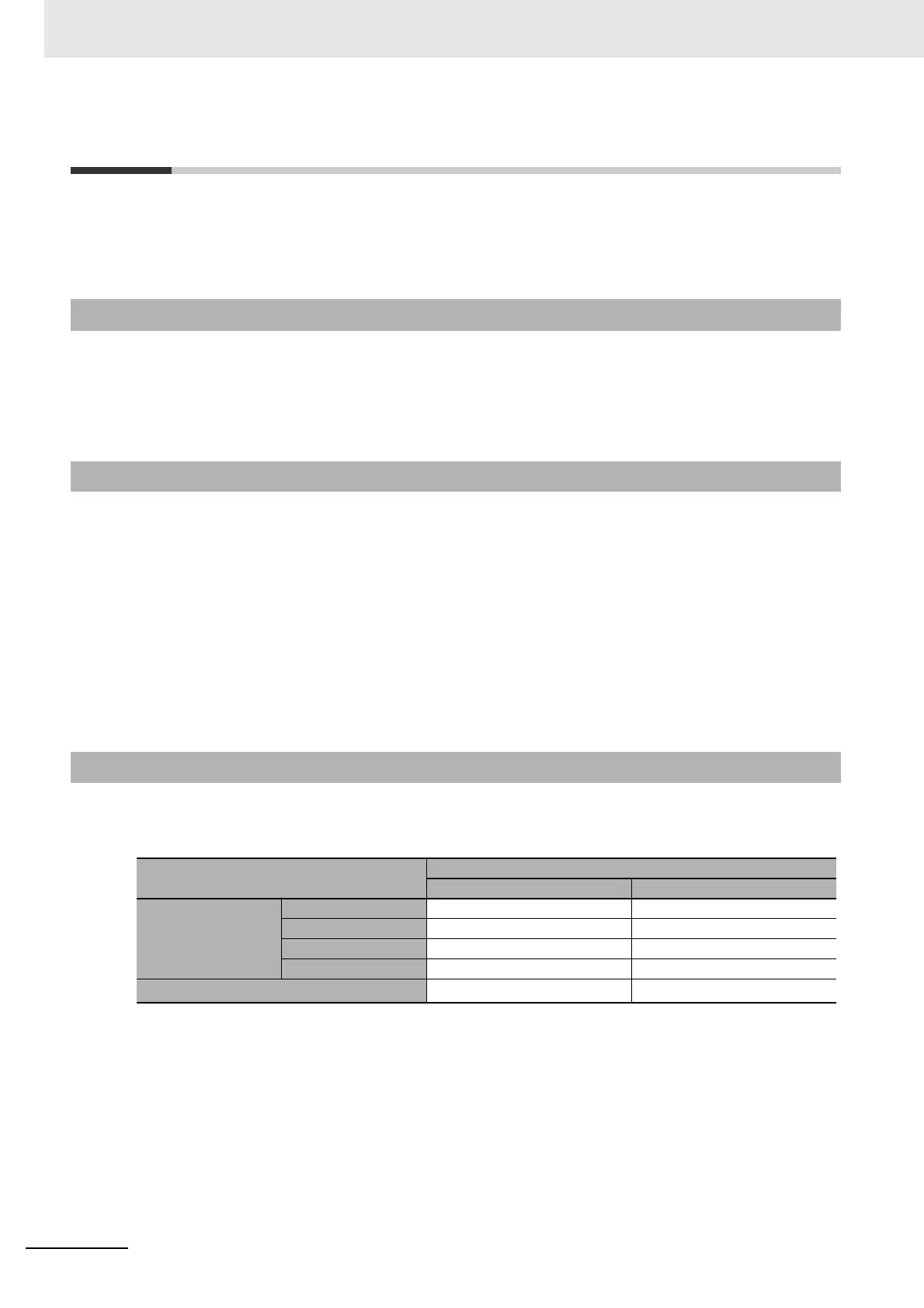

There are five types of user-defined variables as defined according to their function in a POU.

OK: Definable.

7-2-1 Variables

7-2-2 Types of Variables

7-2-3 Types of User-defined Variables

Type of user-defined variable

POU type

Programs Function blocks

Local variables

Internal variables OK OK

Input variables None OK

Output variables None OK

External variables OK None

Global variables

OK

*1

*1. You can define global variables as external variables to access the global variables through the ex-

ternal variables.

None

Loading...

Loading...