7 Programming

7 - 20

NX-series Safety Control Unit User’s Manual (Z930)

7-3 Constants (Literals)

This section describes constants.

The value of a variable changes depending on the data that is assigned to that variable. The value of a

constant never changes.

Unlike variables, constants are not stored in memory. You can use constants in the algorithm of a POU

without the need to declare them.

Constants have a data type in the same way as variables.

The following types of constants can be used with Safety Control Units.

•Bits

• Numbers

• Bit strings

•Times

The following tables show the notation to define different constants for the Safety Control Unit. The con-

stant is normalized after it is entered.

Integers

7-3-1 Constants

7-3-2 Types of Constants

Bits

Notation Example Remarks

TRUE or FALSE FALSE or TRUE

{data_type}#{numeric_value] bool#0 or bool#1 Data type: BOOL

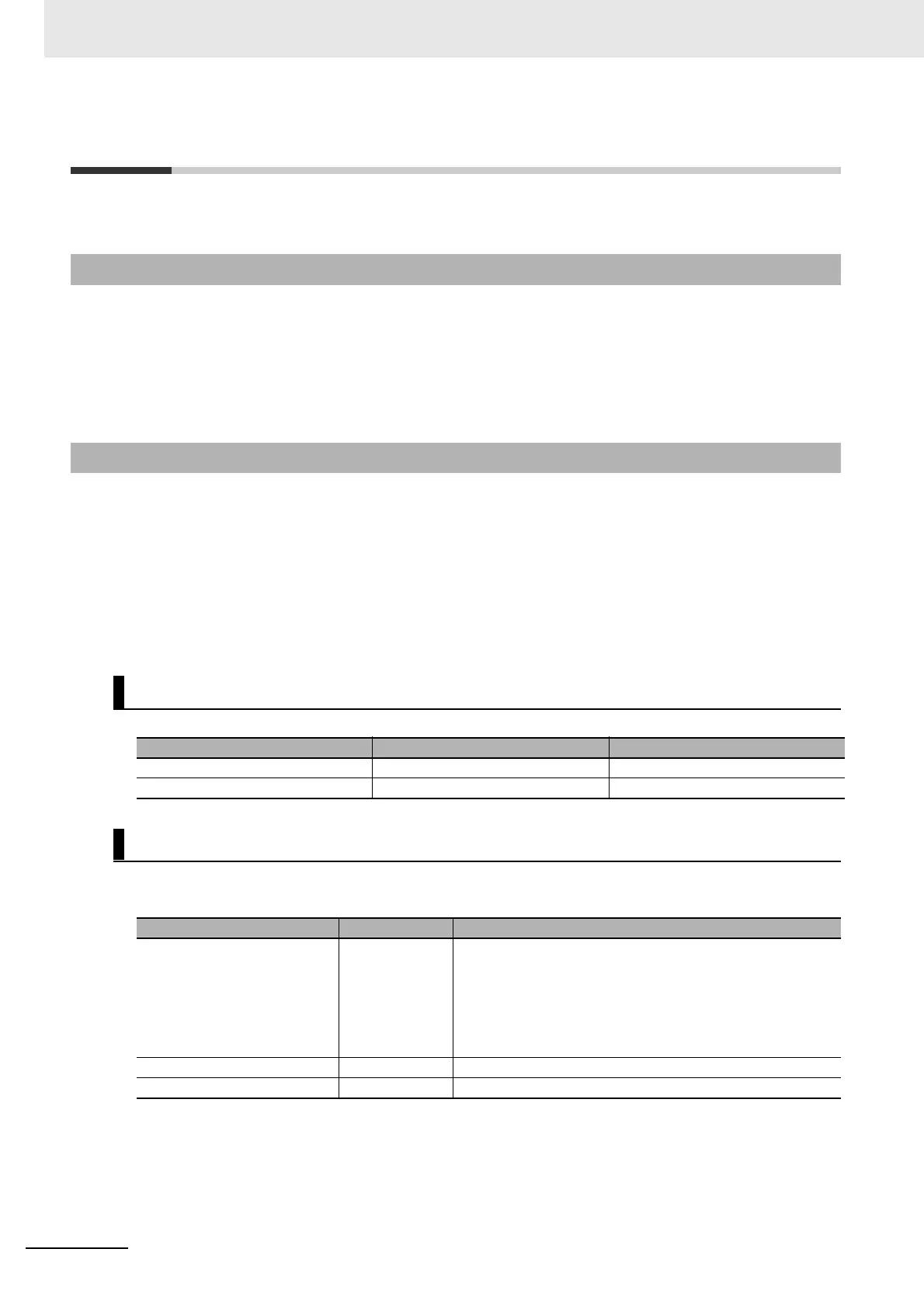

Numbers

Notation Example Remarks

{data_type}#{base}#{numeric_

value]

int#10#1 • Data type: int or dint

• Base: 2, 8, 10, or 16

The editor on the Sysmac Studio does not show the base

of 10. Values entered as the base of 8 are converted to

decimal numbers.

• Numeric values cannot be signed (+ or −).

{data_type}#{numeric_value] int#1 This is interpreted as decimal data.

{numeric_value} −100 This is interpreted as SAFEINT or SAFEDINT data.

Loading...

Loading...