11 - 27

11 Adjustment Functions

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

11-11 Friction Torque Compensation Func-

tion

11

11-11-3 Operation Example

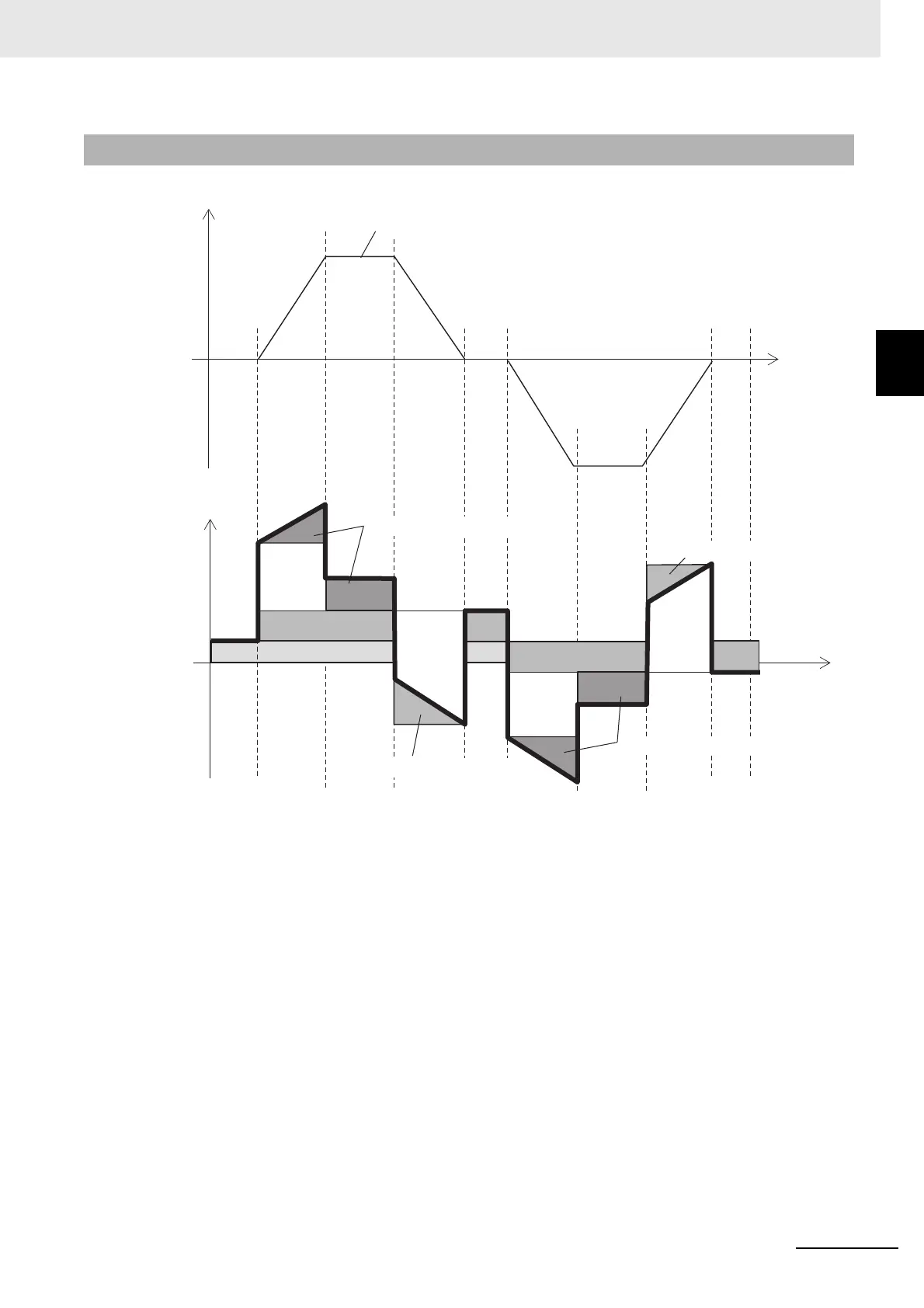

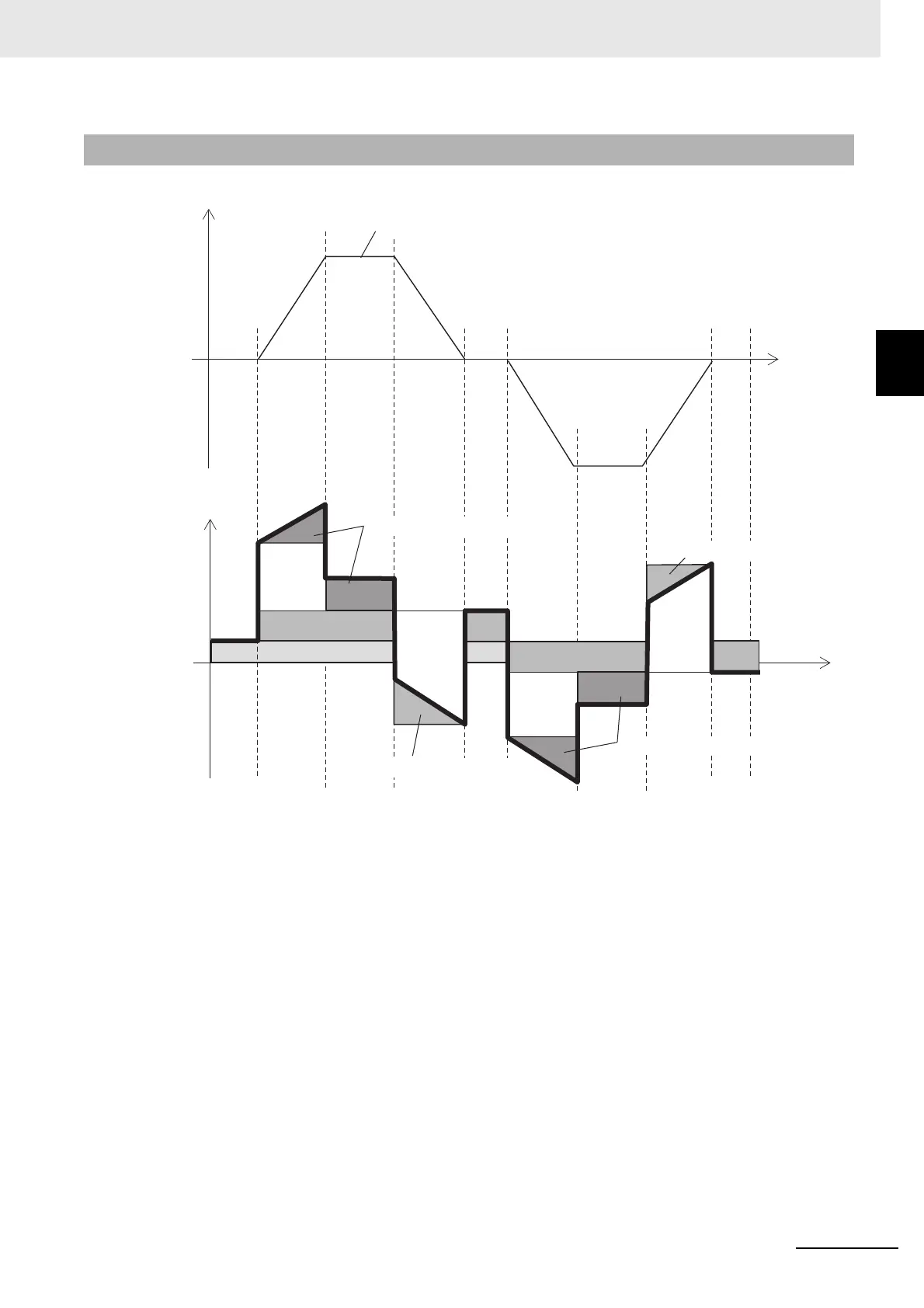

The friction torque compensation is applied according to the operation as shown in the drawing below.

Note The dynamic friction compensation holds the compensation value until the command direction changes, in

order to sustain the position during stabilization.

By setting the torque command value in Unbalanced Load Compensation (3310-02 hex), you can

reduce the variations of positioning operations that occur depending on the movement directions. This

object is useful when a constant amount of unbalanced load torque is always applied to the Servomotor

at axes such as a vertical axis.

By setting the friction torque for each rotation direction in Positive Dynamic Friction Compensation

(3310-03 hex) and Negative Dynamic Friction Compensation (3310-04 hex), you can reduce deteri-

oration of and inconsistencies in the positioning stabilization time due to dynamic friction. These objects

are useful for loads that require a larger amount of dynamic friction torque for a radial load, such as the

belt-driven shaft.

11-11-3 Operation Example

Viscous friction compensation

Time

Time

Command velocity

Negative

direction

Positive

direction

Viscous friction compensation

Viscous friction compensation

Unbalanced Load Compensation

Positive Dynamic

Friction Compensation

Viscous friction compensation

Negative Dynamic

Friction Compensation

Loading...

Loading...