8 - 11

8

- Check the diameter of both the driving shaft supports

according to the axis and planes shown in the figure.

The half shafts are subdivided in Class 1 and Class 2,

as shown in the table below.

Standard

diameter

Class 1

Class 2

40.010 - 40.016

40.016 - 40.022

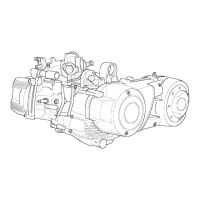

Driving shaft alignment check

- Assemble the driving shaft on the support. Measure

the disalignment in the 4 points shown in the figure.

Specific tool:

Support for driving shaft control 020074Y

05_270_2

05_270_1

Driving shaft crankcase

Max. out-of-line allowed: A = 0.15 mm

B = 0.01 mm

C = 0.01 mm

D = 0.10 mm

- Check the condition of the driving shaft cone, tange

seat, oil seal housing, and the threading.

- If necessary, replace the driving shaft.

N.B.: The main bearings cannot be ground.

The connecting rod cannot be replaced. To check the

connecting rod small end, see Chapter 7-Thermal Unit

and Timing System.

- While cleannig the driving shaft, make sure that no

dirt enters the shaft lubrication hole.

Loading...

Loading...