3 - 10

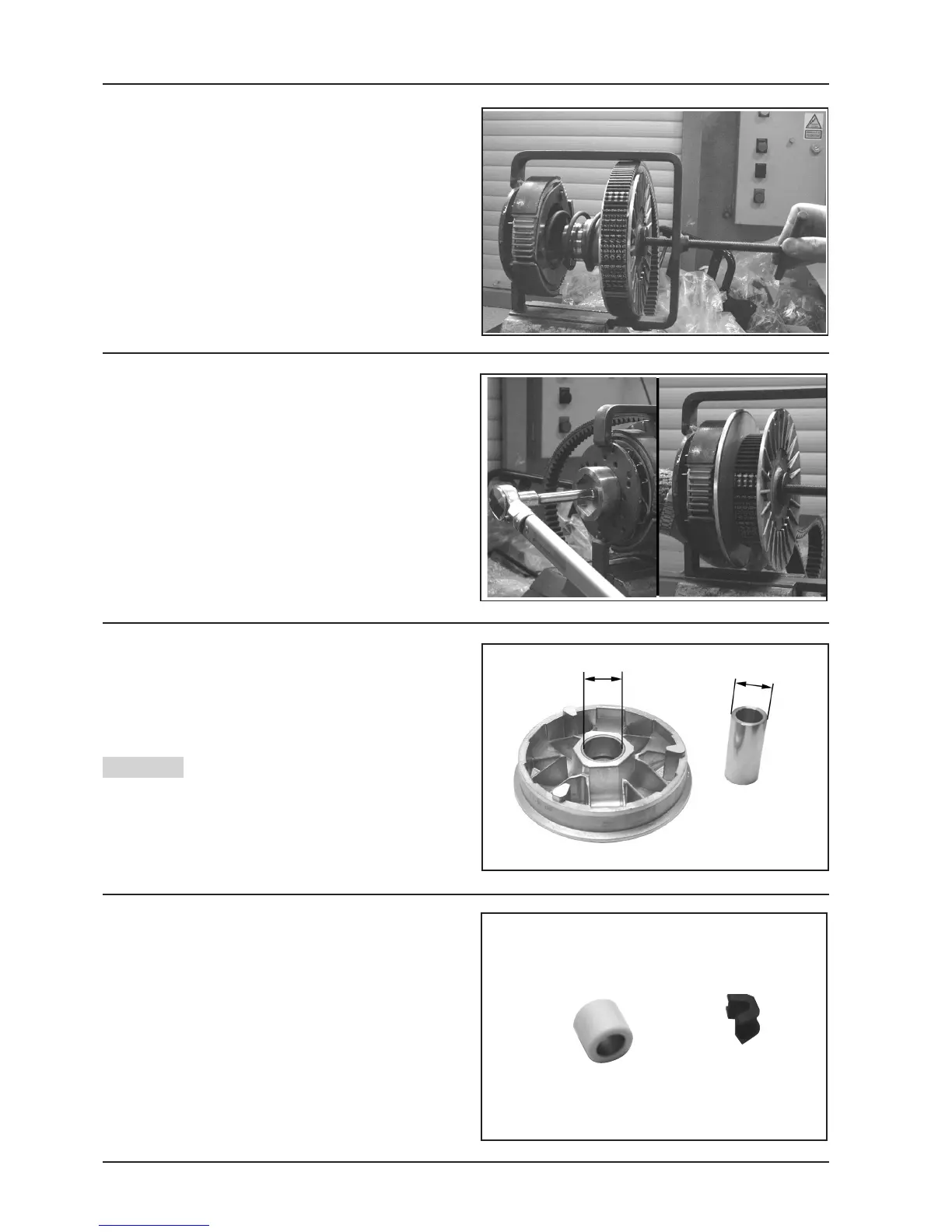

Mobile driving half pulley

- Check that the internal bushes shown in the figure

show no signs of anomalous wear. Measure the I.D.

Maximum allowed diameter: 30.12 mm

Standard diameter: 30.021 mm

- Do not lubricate or clean the bushes.

- Measure the O.D. of the pulley sliding bush shown in

the figure.

Minimum allowed diameter: Ø 29.95 mm

Standard diameter: Ø 29.959 mm

Automatic transmission

05_035

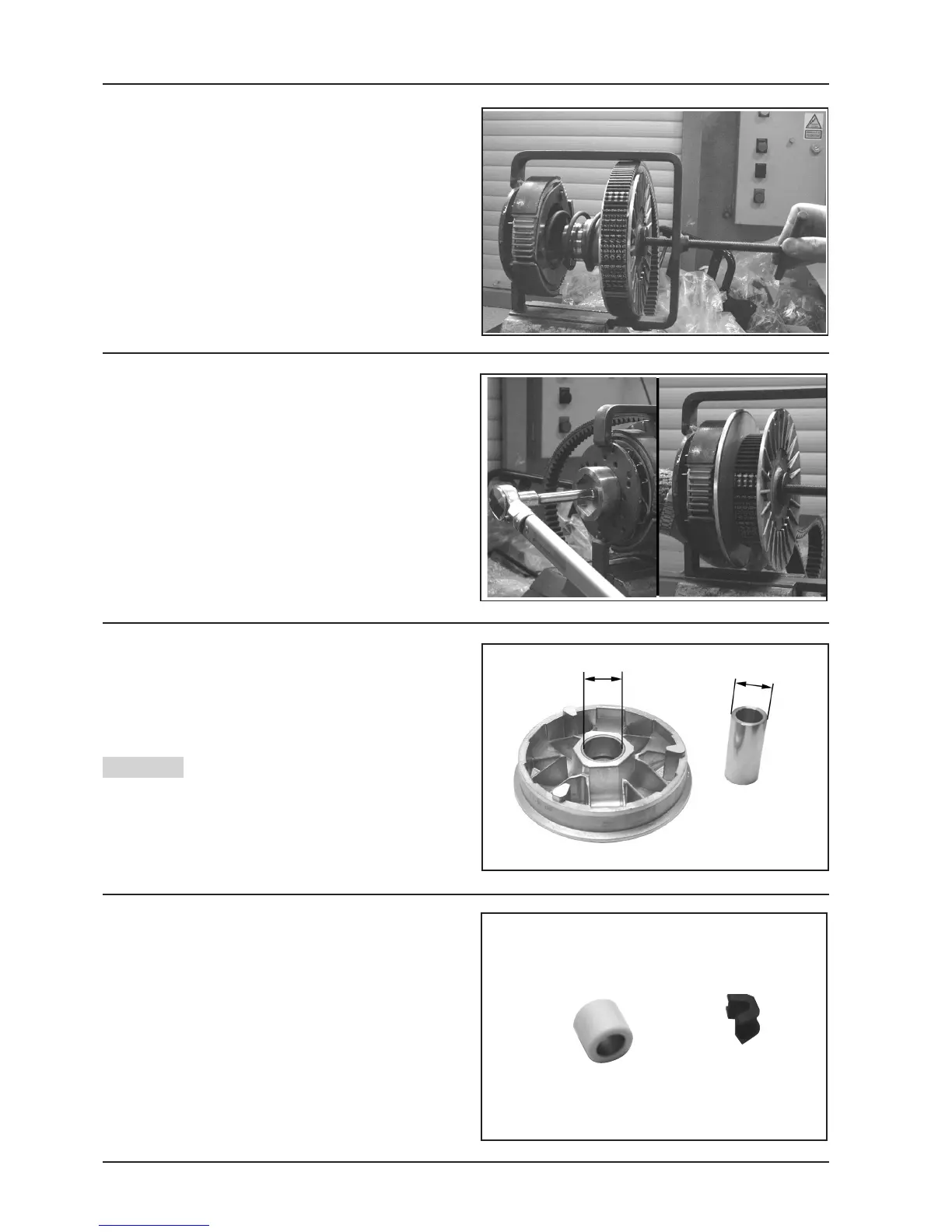

- Check that the rollers are not damaged or worn.

Minimum allowed diameter: Ø 24.5 mm

Standard diameter: Ø 24.9 mm

- Check that the shoes of the roller stop plate are not

worn.

- Check the rollers housing and belt contact surfaces

condition on both half pulleys.

05_036

05_033

- Compress the spring and insert the clutch on the

driven pulley bush.

N.B.: Take care not to damage the sheath or the bush

threaded end.

- Screw the ring nut manually and then tighten it with

the specific wrench to the prescribed torque.

Tightening torque:

Clutch ring nut: 65 - 75 N·m

Specific tool:

55 mm wrench: 020444Y009

- To facilitate the reassembly operation, turn the mobile

driven pulley and fit the belt on the smaller diameter.

05_032

Clutch reassembly

- Prepare the specific tool as already done during the

disassembly phase;

- Preassemble the driven pulley unit with the driving

belt according to its direction of rotation.

- Insert the driven pulley unit, spring with sheath and

clutch in the tool.

Specific tools:

Driven pulley spring compressor 020444Y

Adapter ring 020444Y010

Warning

Loading...

Loading...