8 - 16

05_254

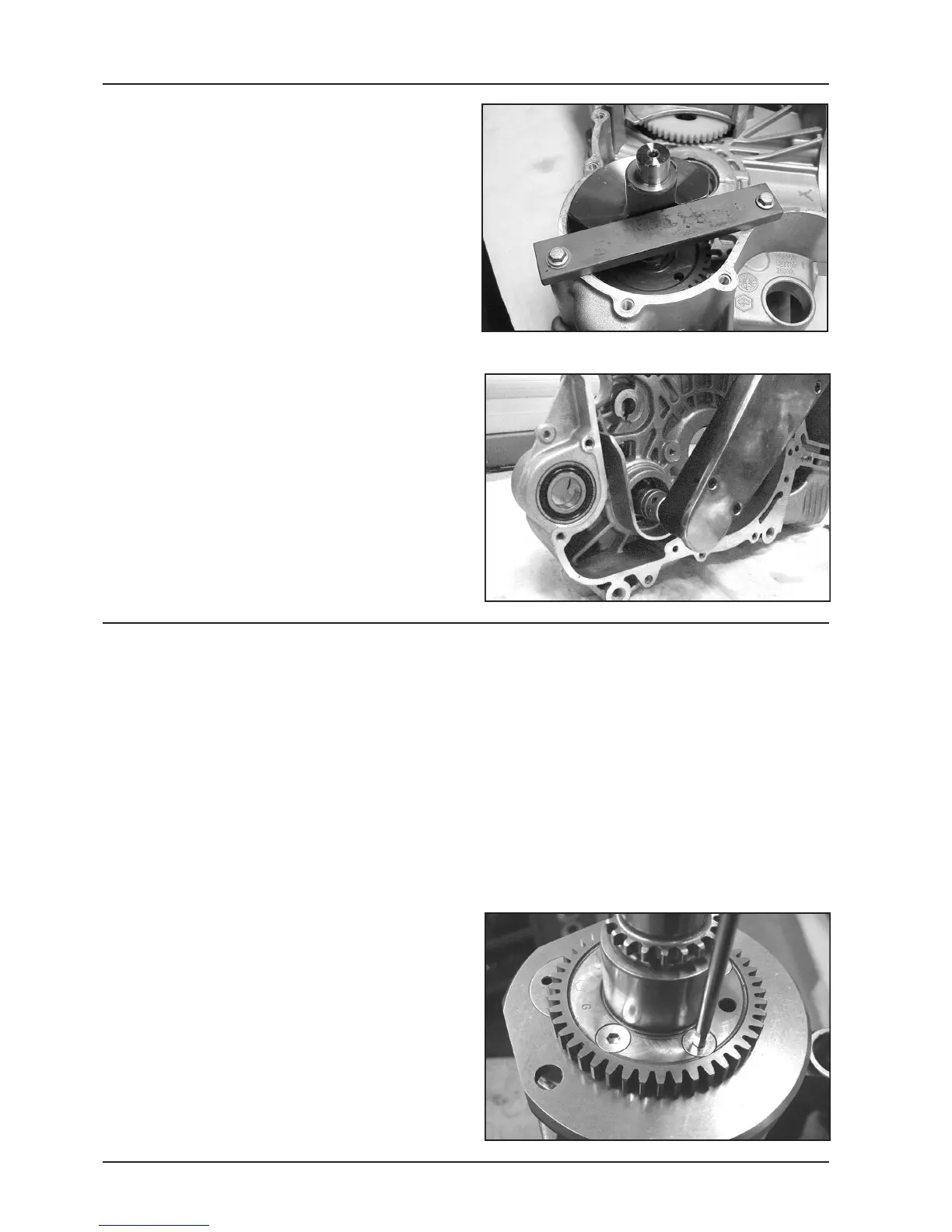

- Assemble the countershaft with the gear on the half

crankcase flywheel side

- Fit the specific tool in the position shown in the figure

Specific tool:

Countershaft lock wrench 020479Y

05_282

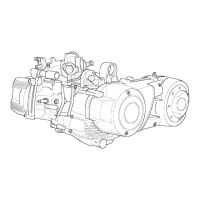

- Hold the countershaft and fit the washer with nut

- Tighten the nut to the prescribed torque, apply

LOCTITE 242

- Remove the specific tool.

Tightening torque:

Countershaft fixing nut: 25 - 29 N·m

Driving shaft crankcase

Driving shaft assembly

- Check that the countershaft control gear and the oil

pump show no signs of dents or deformation. Re-

place if necessary.

N.B.: If the countershaft control gear and the oil pump

are to be replaced, also replace the countershaft gear.

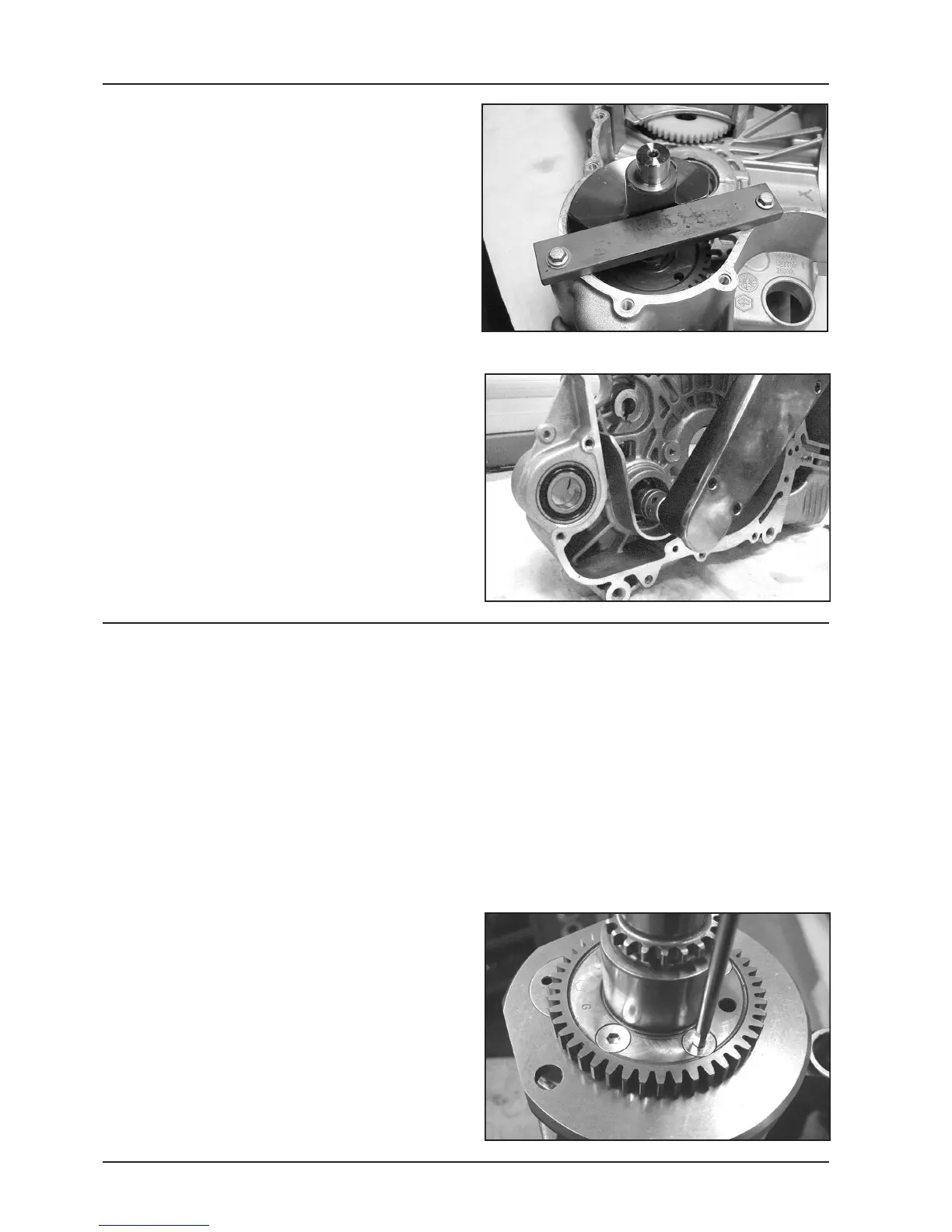

- Before assembling the gear on the driving shaft,

carefully clean the two coupling surfaces by removing

any residuals of LOCTITE from the holes by means of

a brush.

Blow compressed air and degrease the fixing holes

on both surfaces to improve the new LOCTITE set-

ting.

Apply LOCTITE 242 again.

- Repeat the same procedure for the 4 fixing screws.

- Fit the control gear on the driving shaft with the holes

countersink well visible.

- Tighten the 4 fixing screws to the prescribed torque.

N.B.: In order not to damage the screws control hexa-

gon, use a socket wrench with inner hexagon.

Tightening torque:

Driving shaft gear fixing screws: 10 - 12 N·m

05_283

Loading...

Loading...