7 - 11

7

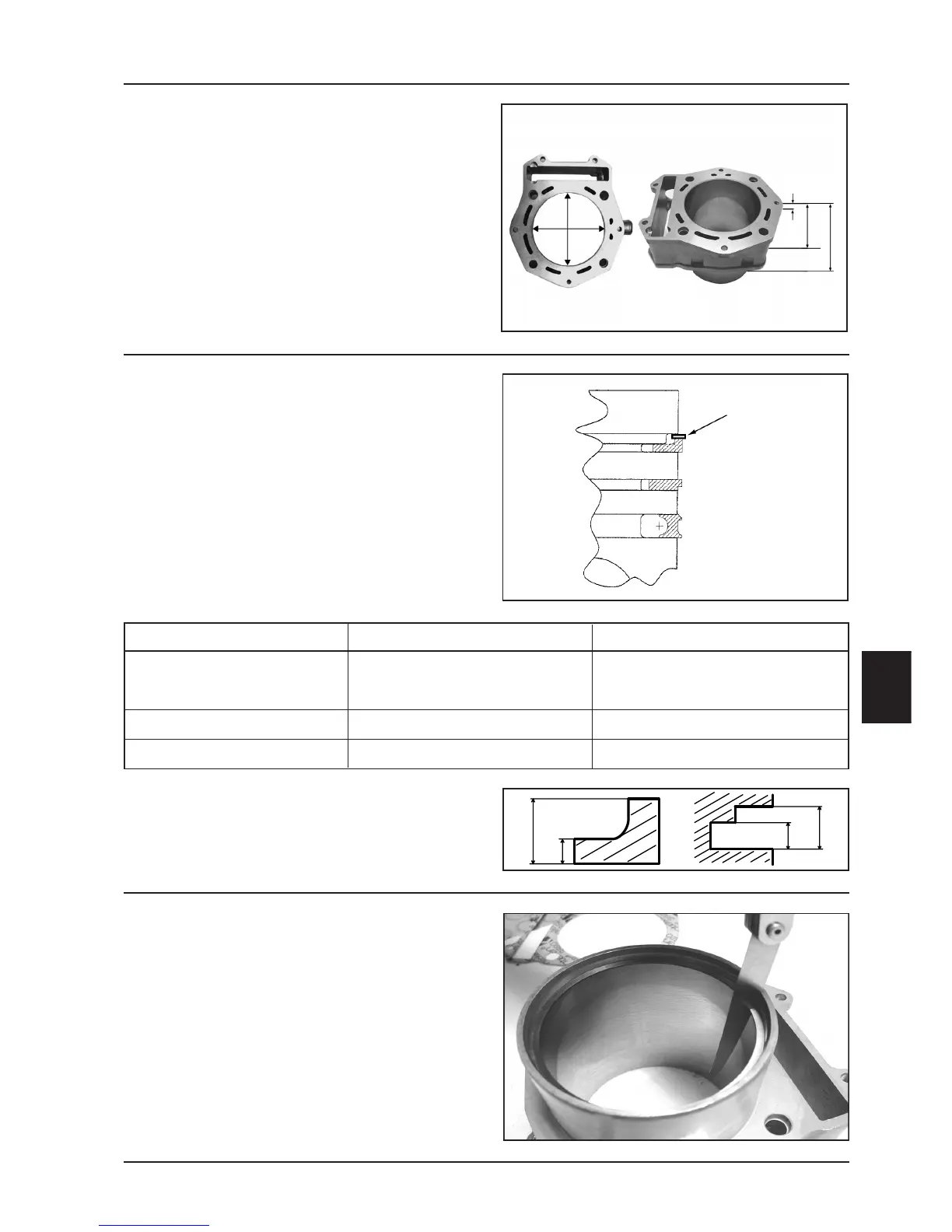

- Measure the cylinder inside diameter by means of a

reamer in the directions shown in the figure and at

three different heights.

Standard diameter: 92

+ 0.018

mm

- Make sure that the lining is not exfoliated.

- Check that the head coupling surface shows no signs

of wear or deformation.

Maximum allowed runout: 0,05 mm

- The pistons and cylinders are classified according to

their diameter. The coupling is made under the same

conditions (A-A, B-B, C-C, D-D).

Piston

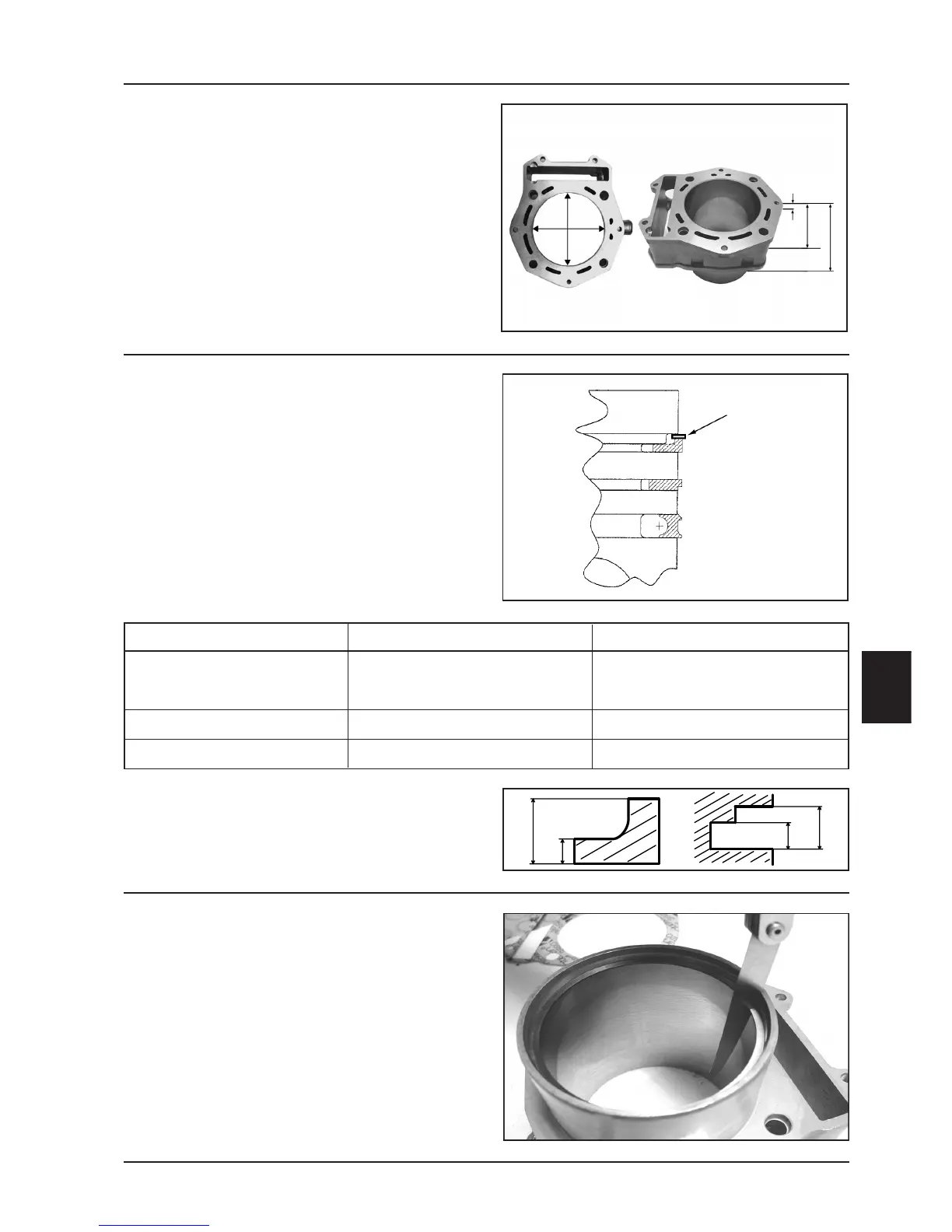

- Carefully clean the gas ring slots.

- With suitable feelers, measure the allowance be-

tween the gas rings and piston slots as shown in the

figure.

- If values higher than those indicated in the table are

measured, replace the piston.

N.B.: Measure the play by inserting the feeler gauge

blade on the 2nd gas ring side.

05_186

05_187

Gas rings

- Insert alternately the 3 gas rings in the cylinder, in the

area of its original diameter. Insert the rings orthogo-

nally to the cylinder axis using the piston to such

purpose.

- Measure the gas rings opening (see figure) by means

of a feeler gauge.

- If values higher than those prescribed are measured,

replace the rings.

05_188

Thermal unit and timing system

+ 0.010

Feeler gauge

Standard allowance Maximum allowance allowed after use

1st compression ring A=0.9

- 0.005

mm C=0.9

+ 0.03

mm

B=1.5

- 0.005

mm D=2

+ 0.05

mm

2nd compression ring 12

- 0.005

mm 1.25

+ 0.03

mm

Scraper ring 2.5

- 0.005

mm 2.5

+ 0.03

mm

Loading...

Loading...