3.9

Engine/Cooling/Exhaust

3

Piston Inspection

Check piston for scoring or cracks in piston crown or pin

area. Excessive carbon buildup below the ring lands is an

indication of piston, ring or cylinder wear.

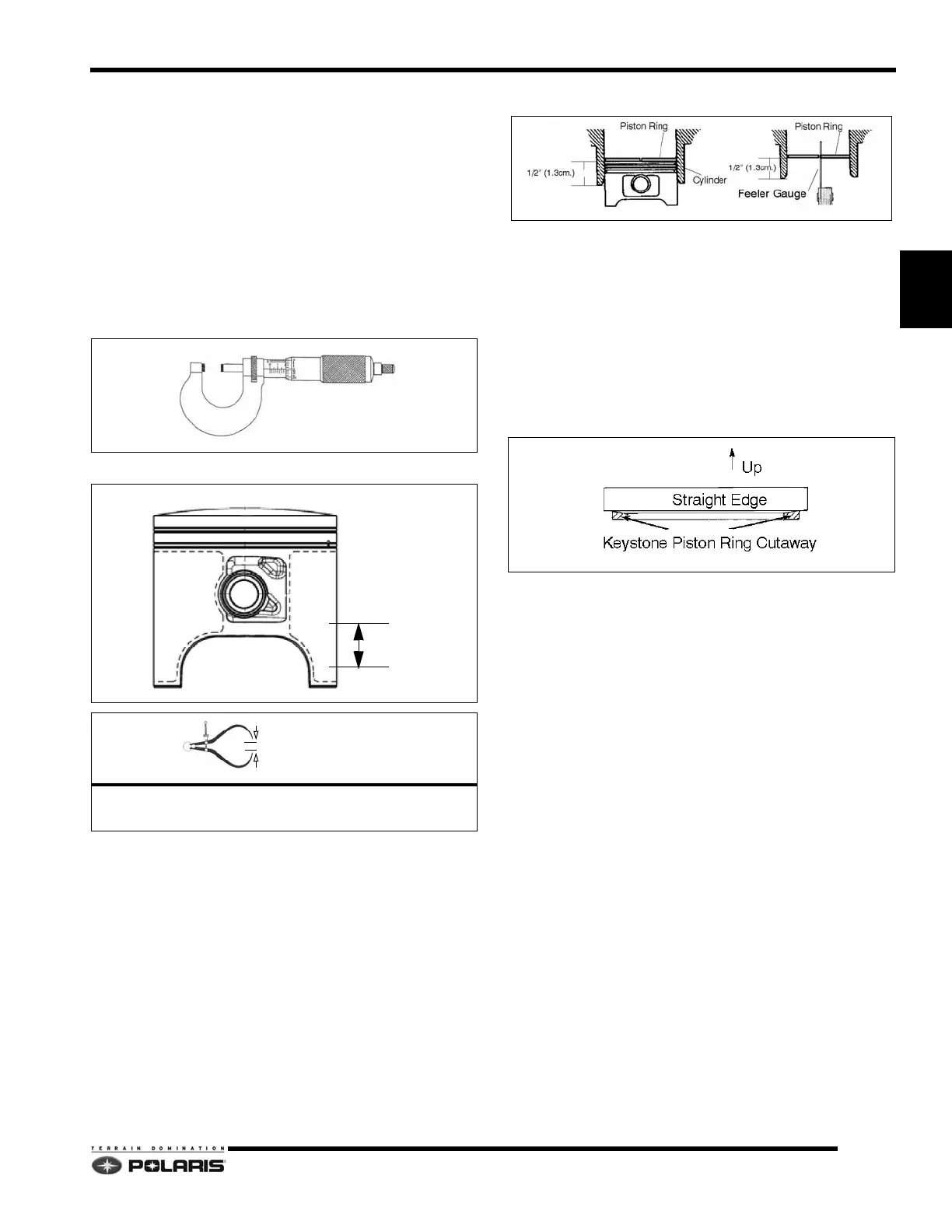

Using only a micrometer, measure the piston outside

d

iameter at a 90° angle to the direction of the piston pin

and at the specified measuring point.

NOTE: A micrometer is the only recommended tool to

ac

curately measure piston diameter.

Subtract this measurement from the minimum cylinder

me

asurement (90° to the pin). If clearance exceeds the

service limit piston/cylinder overhaul may be required.

Piston Ring Installed Gap

Position the ring 20mm from the top of the cylinder using

the piston to push it squarely into place. Measure installed

gap with a feeler gauge at both the top and bottom of the

cylinder.

NOTE: A difference in end gap indicates cylinder

t

aper. The cylinder should be measured for excessive

taper and out-of-round. Replace rings if the installed

end gap exceeds the service limit. Always check

piston ring installed gap after re-boring a cylinder or

when installing new rings.

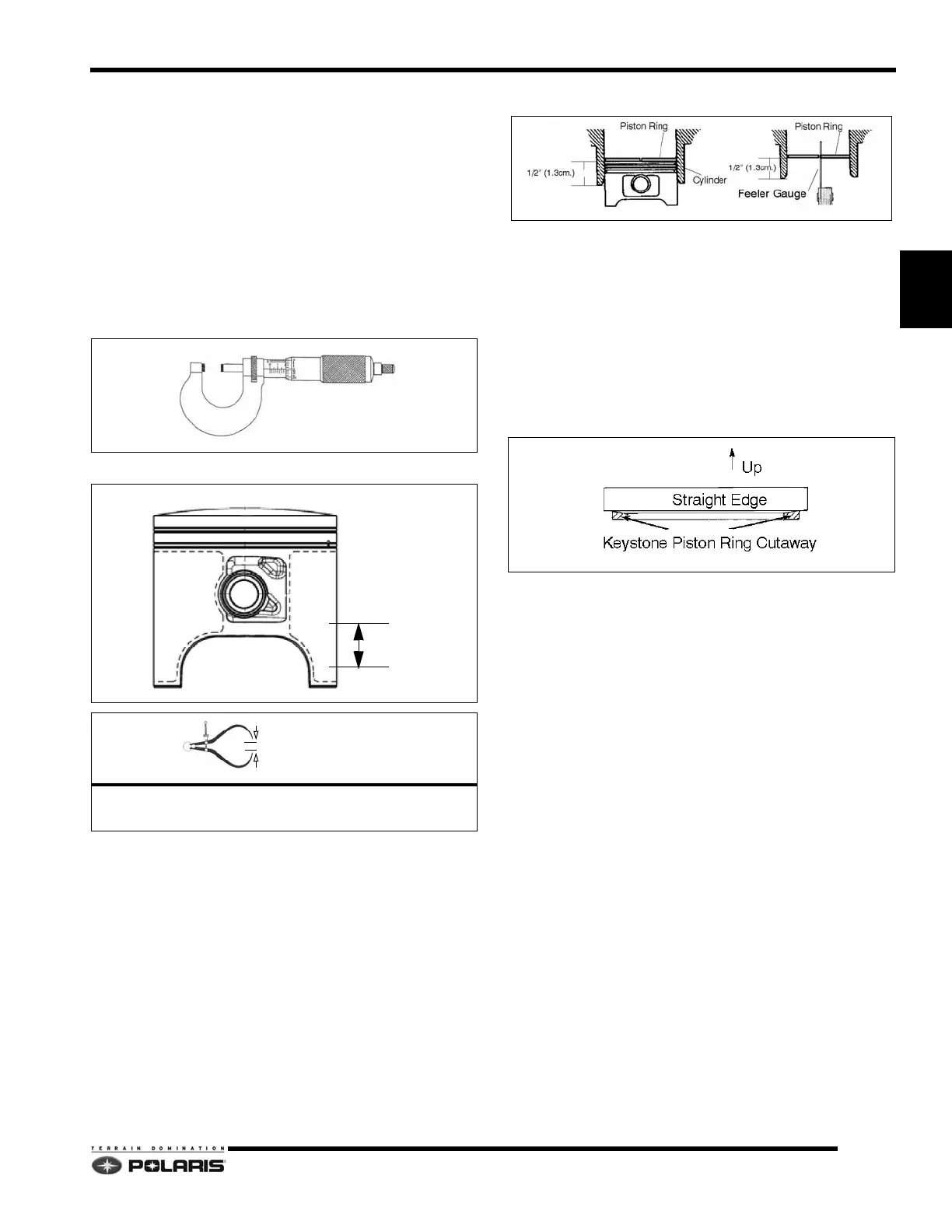

Piston rings are installed with marking or beveled side up.

Measuring Point

600/800 Pistons: 10-20mm

Loading...

Loading...