4.16

Cleanfire Fuel Injection

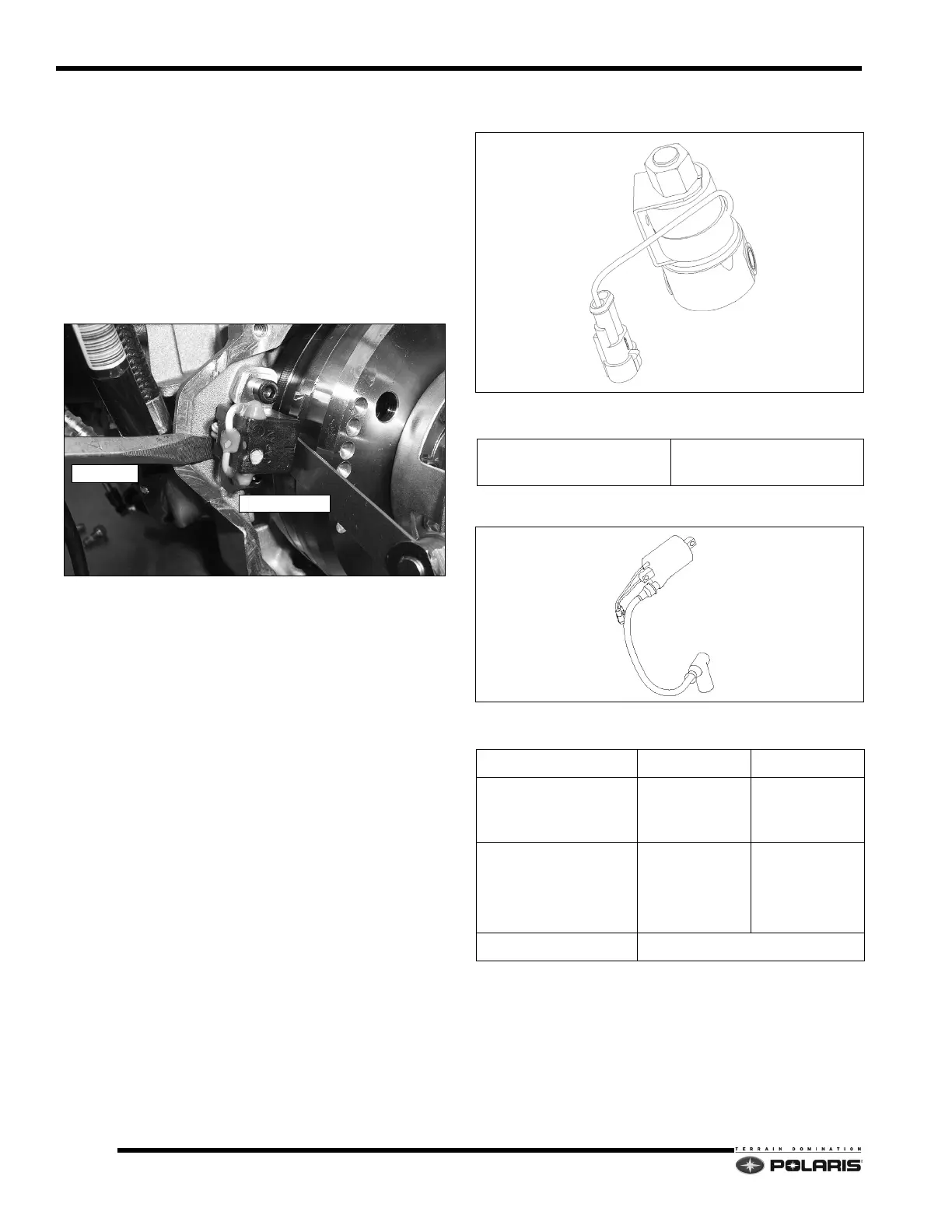

2. Insert the blade of a .030" feeler gauge between the

rib and sensor face. If there is no drag felt on the feeler

gauge, the CPS must be adjusted.

3. To adjust a CPS, use an 8 inch pry bar to carefully

de

flect the sensor.

4. Place the tip of the small pr

y bar between the back of

the sensor and crankcase. insert a .012" feeler gauge

between the sensor face and encoder rib.

IMPORTANT: Do not pry on the individual sensor

wir

es.

5. Gently pry the sensor towards the encoder rip until the

g

auge begins to bind between the components.

6. Re-measure the air gap. The gap should be between

.0

20-.030.

Exhaust Valve Solenoid

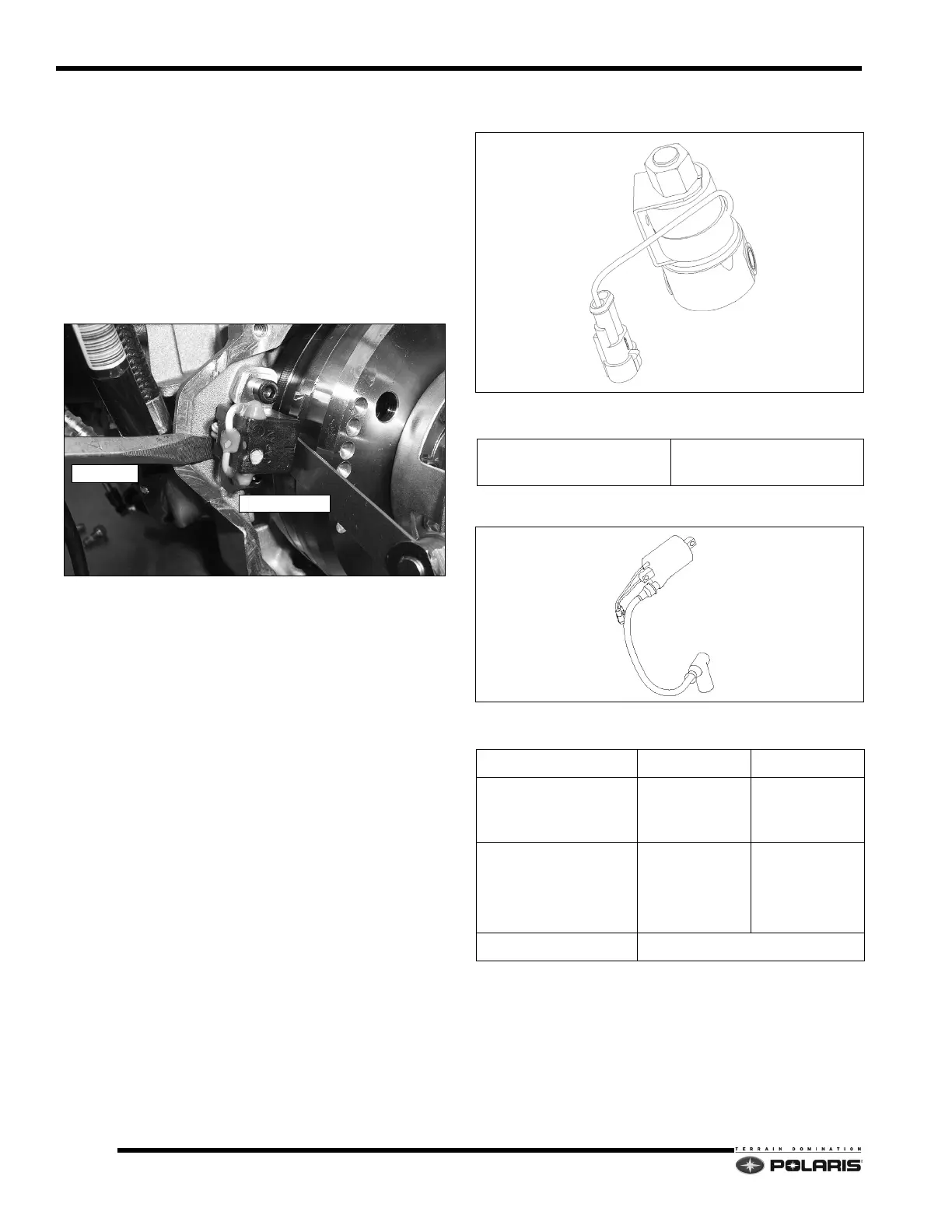

Ignition Coils

Specifications

Coil Resistance

(WHT/YEL to RED)

15 +/-

15% @ 68°F (20°C)

Specifications

DC-CFI 4 DC-CFI 2

Primary Coil

Resist

ance

(Black to White)

0.20 +/-

15%

@ 68°F (20°C)

0.45 +/- 15%

@ 68°F (20°C)

Secondary Coil

Resist

ance

(Without Plug Cap/

Black to

High Tension

Lead)

6.3k +/- 15%

@ 68°

F (20°C)

18k +/- 15%

@ 68°F (20°C)

Plug Cap Resistance 5k+

/- 15% @ 68°F (20°C)

Loading...

Loading...