3.15

Engine/Cooling/Exhaust

3

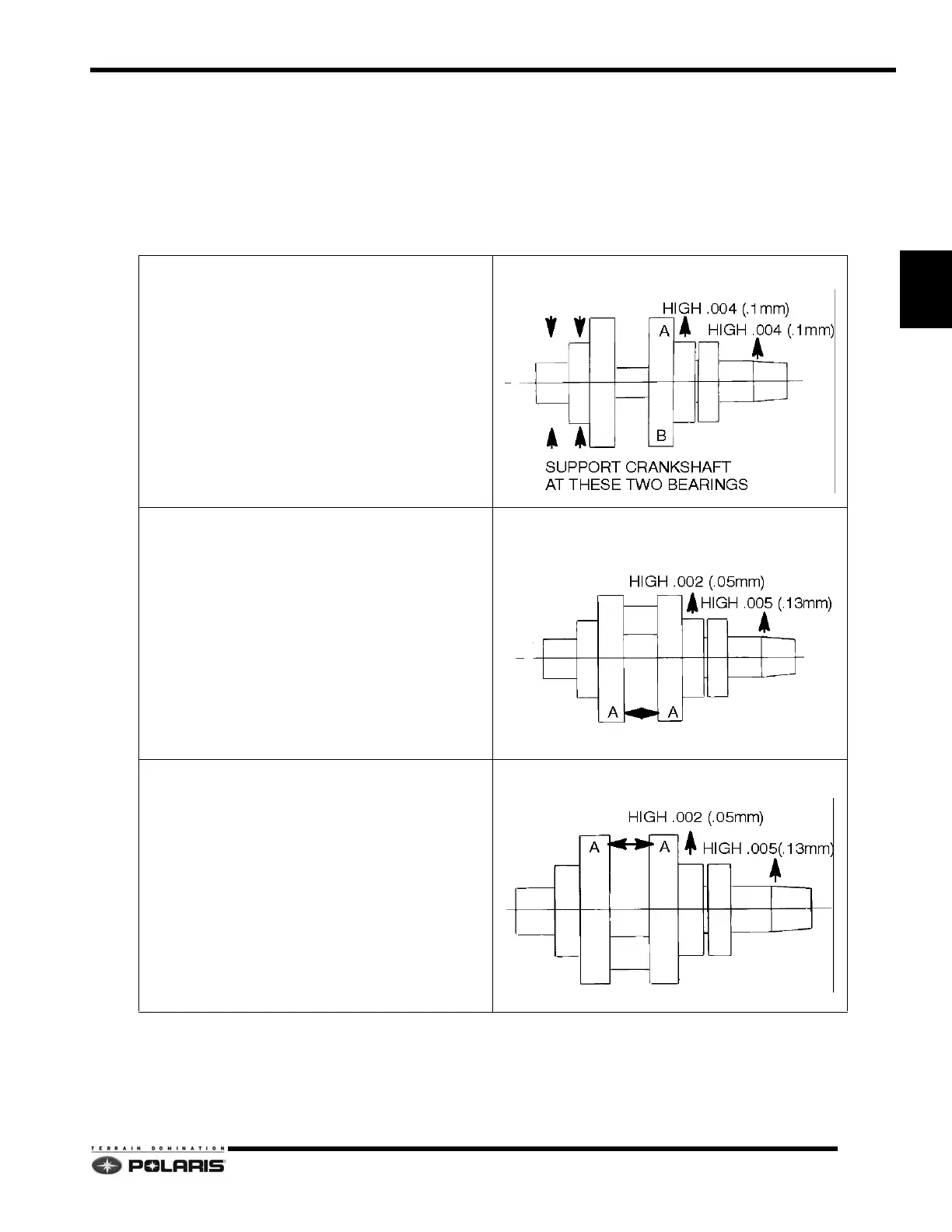

Crankshaft Truing

Lubricate the bearings and clamp the crankshaft securely

in the holding fixture. If truing the crankshaft requires

striking with a hammer, always be sure to re-check

previously straightened areas to verify truing. Refer to the

illustrations below. Use Crankshaft alignment kit PN

2870569.

NOTE: The rod pin position in r

elation to the dial

indicator tells you what action is required to

straighten the shaft.

Truing Examples

To correct a situation like this, strike the shaft at point

A with a brass hammer.

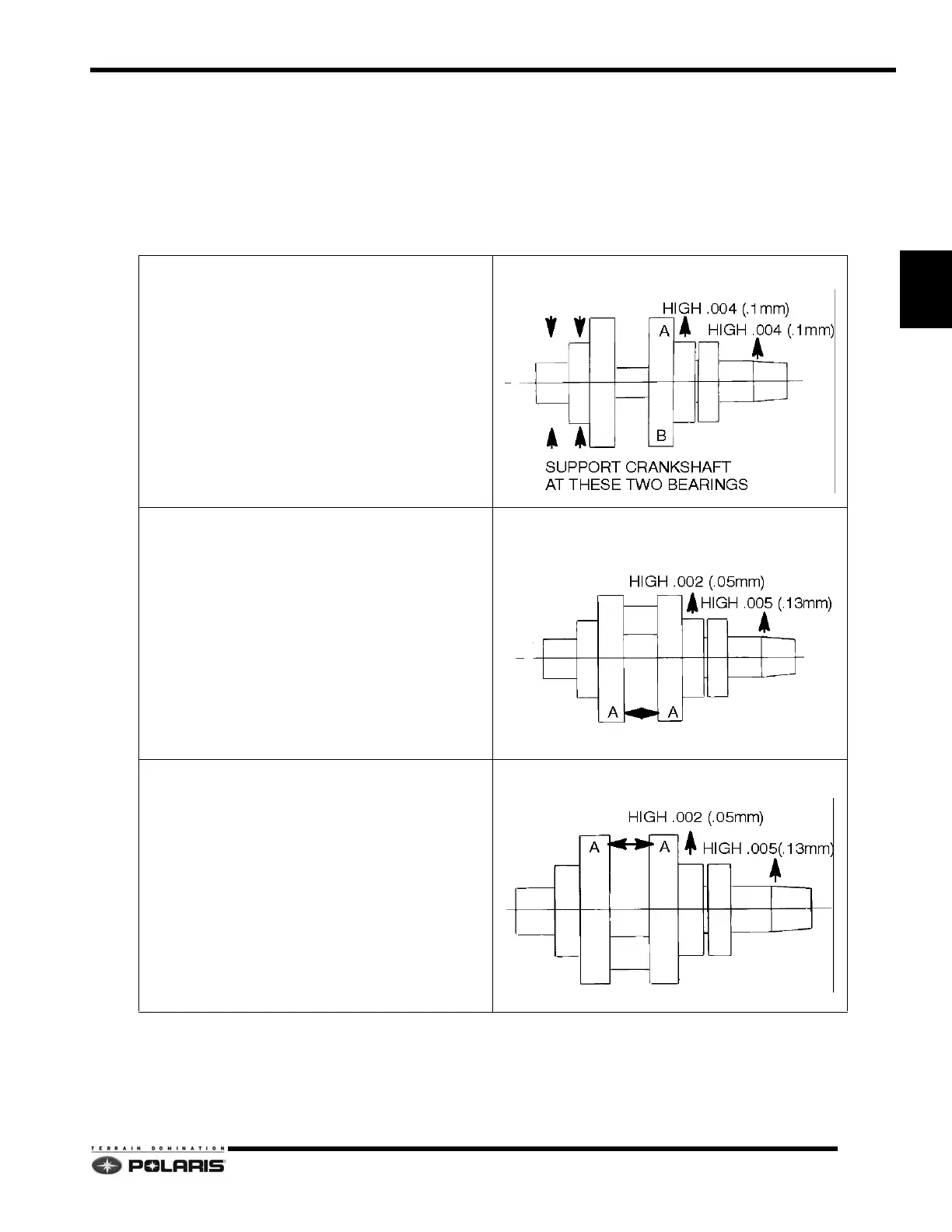

To correct a situation like the one shown here,

s

queeze the crankshaft at point A. You will use the

tool from the alignment kit PN 2870569.

If the crank rod pin location is 180° from the dial

indicator (oppos

ite of above), it will be necessary to

spread the crankshaft at the A position as shown in

illustration 3. When rebuilding and straightening a

crankshaft, straightness is of utmost importance.

Runout must be as close to zero as possible.

Loading...

Loading...