2.17

Maintenance

2

PVT SYSTEM

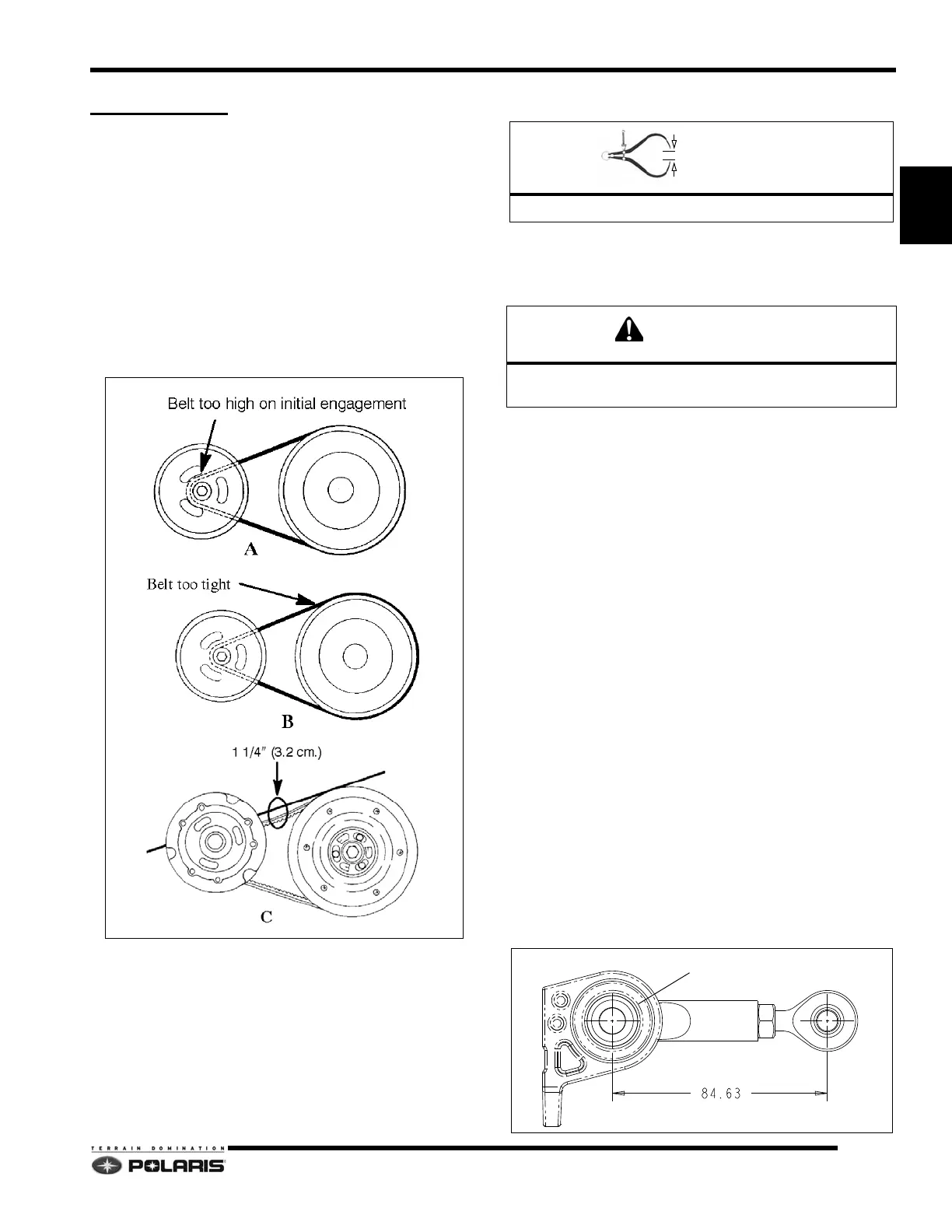

Belt Deflection Inspection

Excessive belt deflection is when the belt is too long or the

center distance is too short. The initial starting ratio will be

too high, resulting in performance loss. This is due to the

belt rising too high in the drive clutch sheaves upon

engagement (A).

Insufficient belt deflection (B) is when

the belt is too short

or the center distance is too long. The initial starting ratio

will be too low. In addition, the machine may creep when

the engine idles, causing damage to the internal face of

the drive belt.

1. Measure the belt deflection with

both clutches at rest

and in their full neutral position.

2. Place a straight edge across the tow clutch

es, on top

the belt.

3. Apply downward pressure to the belt and measure the

di

stance at point (D). Compare to specification.

4. The measurement should be 1-1/4" (3.2cm).

5. If the measurement is not correct, adjust driven clutch.

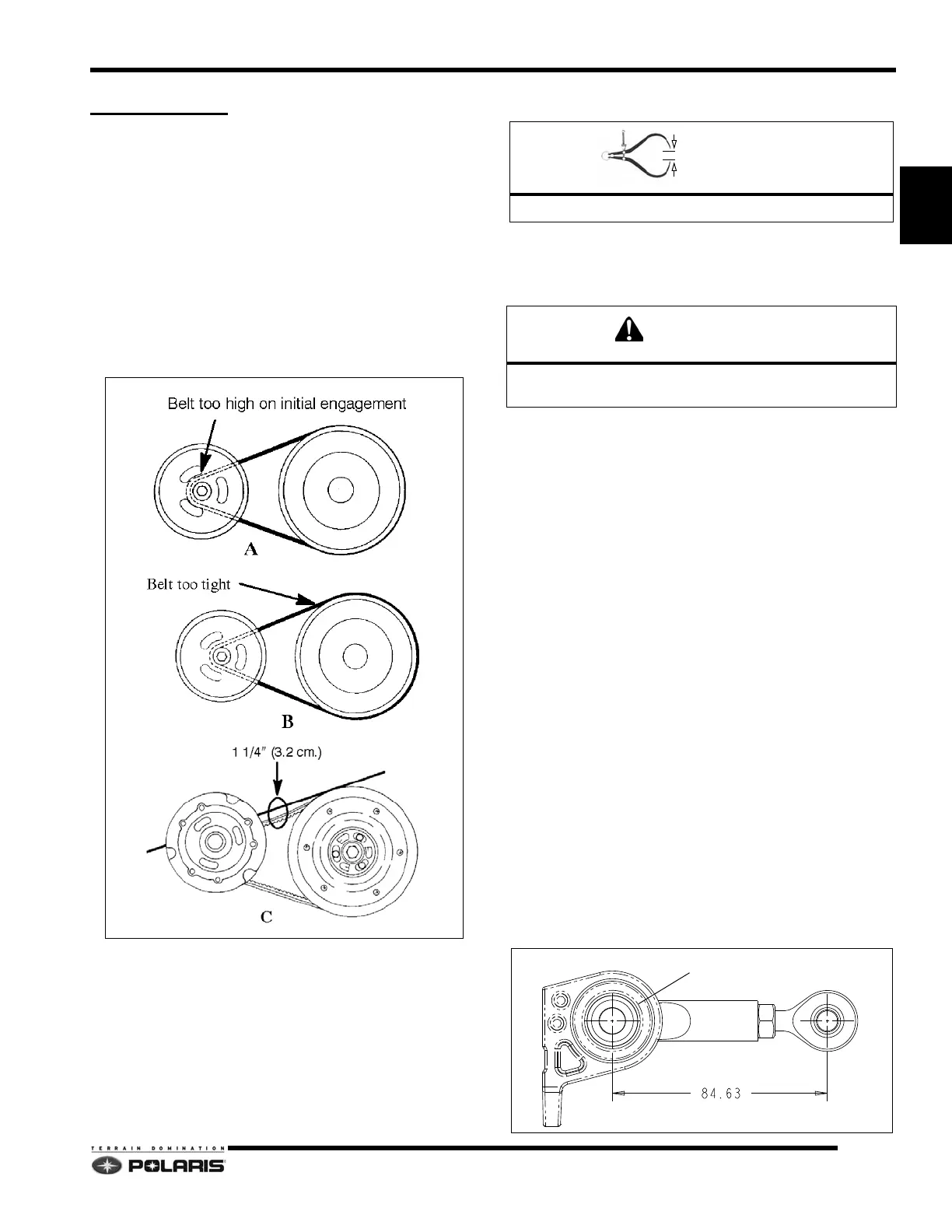

Team/P2 Deflection Adjustment

1. Verify the drive system is in forward drive.

2. While holding the set screw with an Allen wrench,

lo

osen the jam nut.

3. Turn the set screw clockwise while holding the

jam nut

stationary to increase the distance between the clutch

sheaves (increase belt deflection).

4. Turn the set screw counter-clockwise while holding

the

jam nut stationary to decrease the distance

between the clutch sheaves (decrease belt

deflection).

5. Secure the jam nut while holding the set screw

stationary

.

6. Raise the rear of the snowmobile using a track stand

to allow the

track to spin.

7. Start the engine and apply enough throttle to spin the

track

.

8. Turn off then engine, and repeat belt deflection

in

spection.

Torque Limiter

NOTE: 2010 Models Only

Inspect the rubber dampener for signs of abnormal wear

an

d tear. Adjust the linkage length to specification.

Belt Deflection: 1.25" (3.2cm)

The driven clutch can be damaged if the clutch is in

reverse drive.

Loading...

Loading...