116 Rockwell Automation Publication 750-IN118A-EN-P - May 2021

Chapter 5 Service and Maintenance

Commonly Used Tools Table 22 includes the tools that are needed for test measurements, basic

maintenance, and service repairs.

IMPORTANT

Make sure that tools and/or hardware components do not fall inside

configured bay assemblies. Do not energize the PowerFlex 755T Drives

Configured to Order Program product unless all loose tools and/or

hardware components have been removed from the configured bays,

drive assemblies, and drive bays.

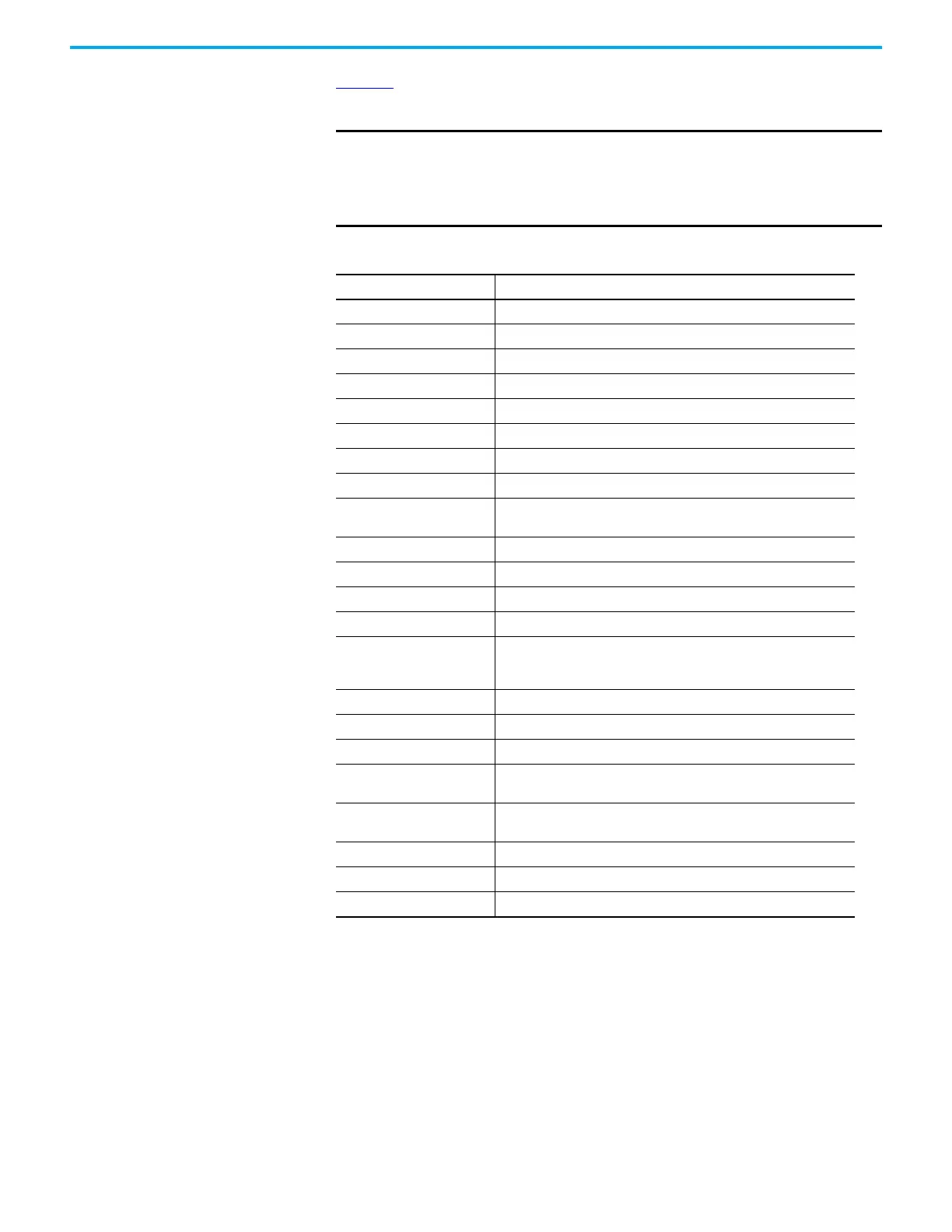

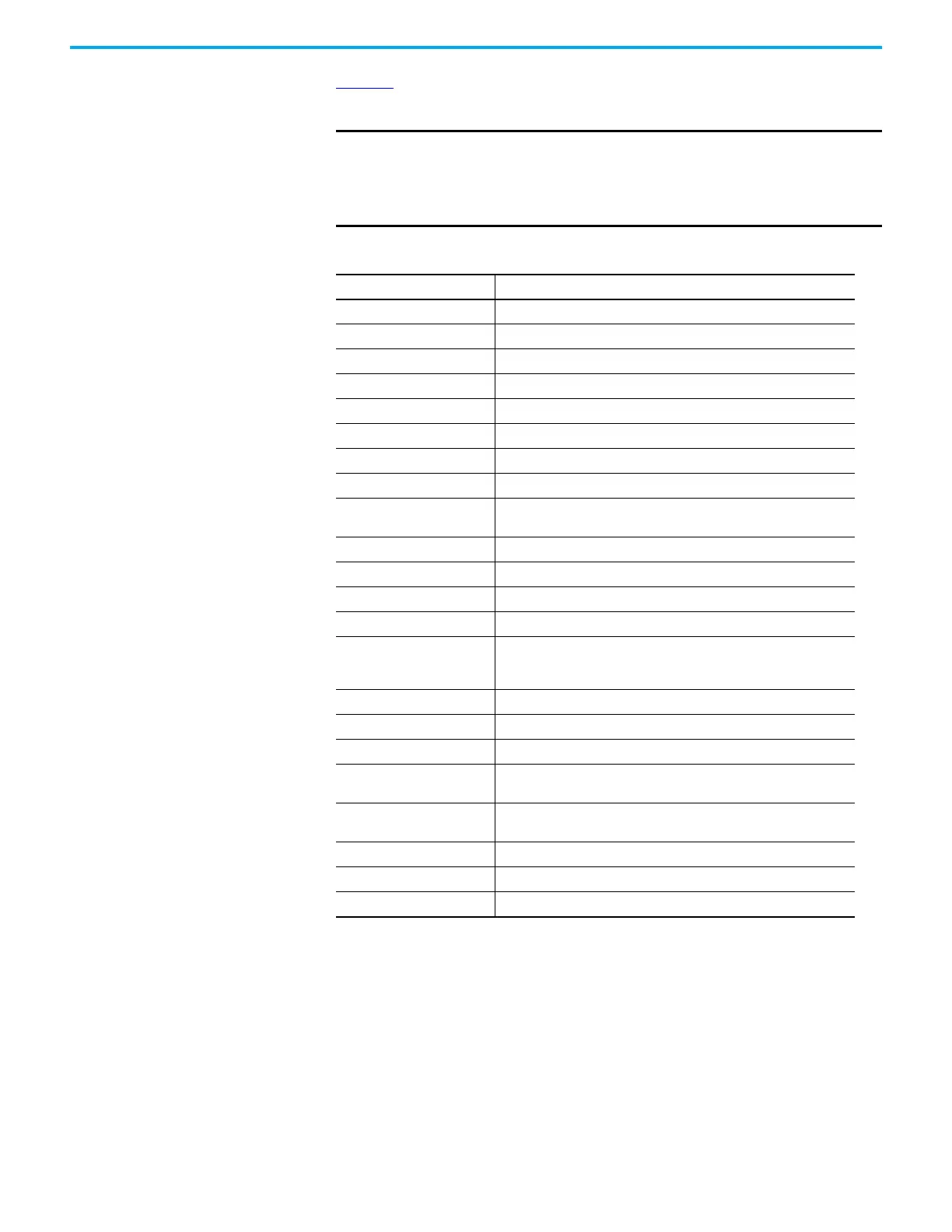

Table 22 - Service Tools

Tool Description Details

Allen socket wrench 3 mm

Box wrench 7 mm, 8 mm, 10 mm, 13 mm, 15 mm, 17 mm, 19 mm, 22 mm

Crimp tools For cable terminals 1.5...240

Current clamp 1000 A (AC, rms), signal output

ESD-protected place of work Work surface, Floor cover, seat, and ground connections

ESD-protective clothing Wrist wrap, shoes, overall clothing (coat)

Flashlight —

Flat-nose screwdriver 3 mm (0.12 in.), 5 mm (0.19 in.), 6.4 mm (0.25 in.)

Torx, star, or hexalobular

screw driver/bit

#15, #20, #25, #30, #40, #45

Hexagonal socket wrench 2.5 mm, 7 mm, 8 mm, 10 mm, 12 mm, 13 mm, 17 mm, 18 mm

Insulation tester 1000V DC

Level —

Lift strap 5/16 in. J-hook style, 24 in. long, 1000 lb. Minimum

Multi-meter

Digital multi-meter, capable of AC and DC voltage, continuity, resistance,

capacitance measurements, and forward diode bias tests. Fluke model

87 III or equivalent.

Nose pliers —

Oscilloscope Portable, digitizing, dual channel scope, with isolation

Phillips screwdriver/bit #1, #2

Module service cart

The optional module service cart (20-750-MCART1) is recommended to

handle and transport power and filter modules.

Module storage hardware

Module storage hardware (20-750-MINV-ATIP) helps to stabilize power

and filter modules during temporary storage after removal.

Torque wrench 1...12 N

•m (8.8…106 lb•in)

Torque wrench 6...50 N•m (53…443 lb•in)

Wire cutter —

Loading...

Loading...