34 Rockwell Automation Publication 750-IN118A-EN-P - May 2021

Chapter 2 Prepare for Installation

Location Planning When choosing the installation location for your product, make sure that the

location meets the following requirements:

• Allows the product to be installed in a vertical orientation as shown in the

drawings.

• Provides a flat and level mounting surface, allowing the product to make

full contact with the mounting surface and stay stable.

• Allows the bays to be square, and not deformed in any way.

• Provides a mounting surface that can support the weight of the product.

See Approximate Weights on page 31

.

• Does not expose the product to environmental conditions that are

inconsistent with the Environmental Specifications

.

• Provides sufficient space for the product given its dimensions, required

clearances, and access requirements. These topics are covered in the

following sections:

- Approximate Dimensions on page 29

- Overhead Clearance on page 37

- Airflow Clearances and Considerations on page 37

- Service Cart Access Requirements on page 39

Also consider the following when choosing the installation location for your

product:

• Ventilation and air conditioning concerns beyond meeting the ambient

temperature requirements

• Input power cable entry points

• Motor cable exit points

• Alignment with other equipment

• Future needs

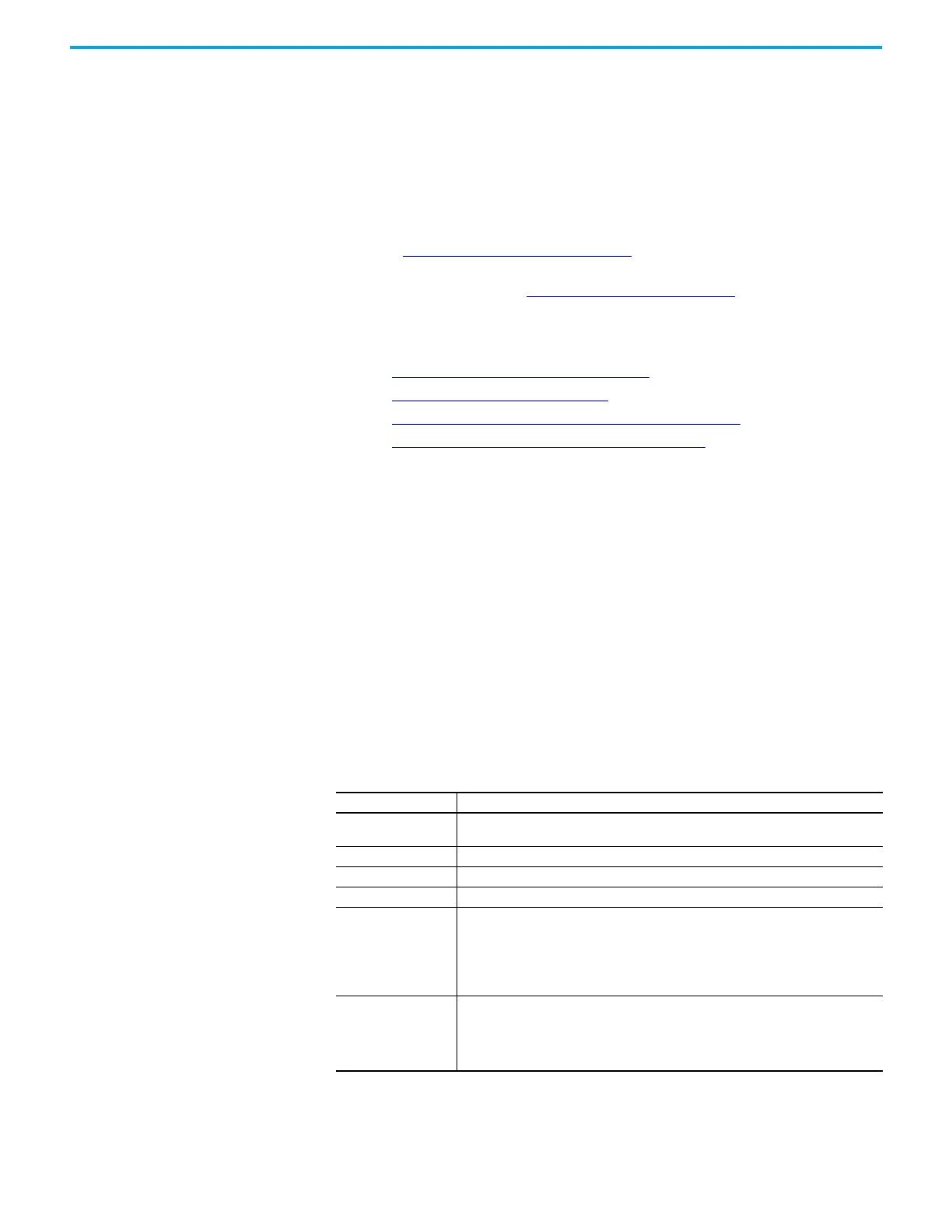

Environmental Specifications

The installation site must be compatible with the degree of protection that is

provided by the bay. PowerFlex 755T products are only intended for indoor use.

Category Specifications

Ambient operation

temperature

IP21, UL Type 1: -20…+40 °C (-4…+104 °F) Frames 8 and 9, All Ratings

IP54, UL Type 12: -20…+40 °C (-4…+104 °F) Frames 8 and 9, All Ratings

Storage temperature -40…+70 °C (-40…+158 °F)

Relative humidity 5…95% noncondensing

Pollution degree Pollution Degree 2 per UL61800-5-1.

Shock (acceleration) The configured bays have the same shock specifications as the 755T drive bays.

Operating shock

Cabinet packaged products – 10 g peak for 11 ms duration (±1.0 ms), three shocks in each

direction in each axis

Packaged for shipment

shock

Meets ASTM International standards

Vibration The configured bays have the same vibration specifications as the 755T drive bays.

Operating vibration Cabinet packaged products – 1.000 mm (0.040 in.) displacement, 1 g peak

Packaged for shipment

vibration

Meets ASTM International standards

Loading...

Loading...