26 Rockwell Automation Publication 750-IN118A-EN-P - May 2021

Chapter 1 Product Overview

Commonly Used Installation

Tools

This section provides information about tools that are used to install and

configure PowerFlex 755T Drives Configured to Order Program products.

Installation Tools

This list includes the tools that are needed for installation and test

measurements.

IMPORTANT

Make sure that tools and/or hardware components do not fall into open

drive assemblies. Do not energize the product unless all loose tools

and/or hardware components have been removed from the bays.

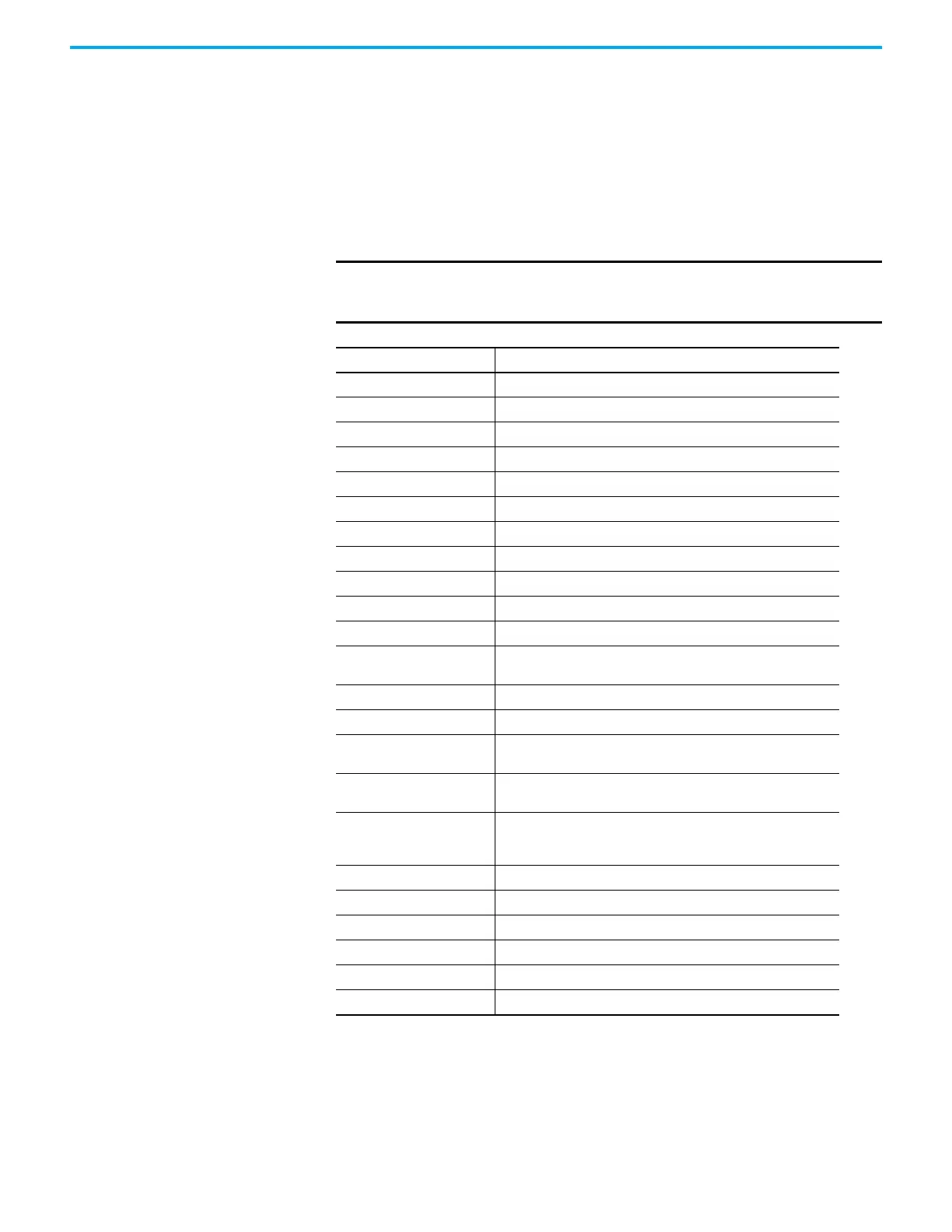

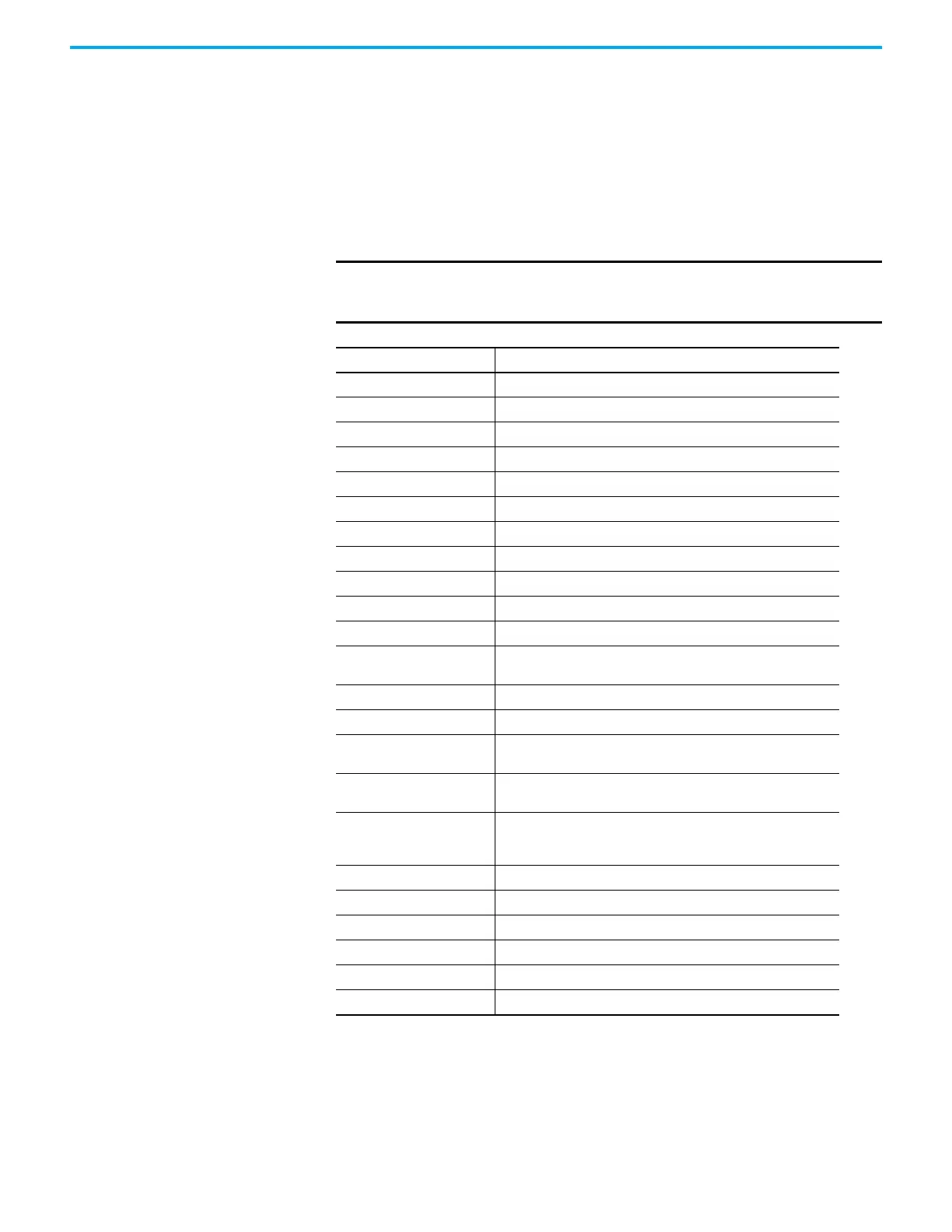

Tool Description Details

Allen socket wrench 4 mm, 5 mm (with long extension)

Allen socket wrench extension 254 mm (10 in.)

Box wrench 7 mm, 8 mm, 10 mm, 13 mm, 17 mm, 19 mm, 22 mm

Ratcheting wrench 17 mm

Crimping tools For cable terminals 1.5...240

Current clamp 1000 A (AC, rms), signal output

ESD-protected place of work Work surface, floor cover, seat, and ground connections

ESD-protective clothing Wrist wrap, shoes, overall clothing (coat)

Flashlight —

Flat-nose screwdriver 3 mm (0.12 in.), 5 mm (0.19 in.), 6.4 mm (0.25 in.)

Fuse puller —

Hexalobular (star or Torx)

screw driver/bit

#15, #20, #25, #30, #40, #45

Hexagonal socket wrench 2.5 mm, 7 mm, 8 mm, 10 mm, 12 mm, 13 mm, 17 mm, 18 mm

Insulation tester 1000V DC

DCPC module lift

Used together with the module service cart to remove DC precharge

modules.

Module storage hardware

Module storage hardware (20-750-MINV-ATIP) helps to stabilize power

and filter modules during temporary storage after removal.

Multi-meter

Digital multi-meter, capable of AC and DC voltage, continuity,

resistance, capacitance measurements, and forward diode bias tests.

Fluke model 87 III or equivalent.

Nose pliers —

Oscilloscope Portable, digitizing, dual channel scope, with isolation

Phillips screwdriver/bit #1, #2

Torque wrench 1...12 N

•m (8.8…106 lb•in)

Torque wrench 6...50 N•m (53…443 lb•in)

Wire cutter —

Loading...

Loading...