Rockwell Automation Publication 750-TG101A-EN-P - June 2022 17

Chapter 1 Before You Begin Tests, Maintenance, or Repairs

Dielectric Grease

Application

All printed circuit board renewal kits with XT contain PolySi PST-576 dielectric

grease on the edge connectors (where present). The dielectric grease provides

corrosion resistance for the edge connector and receiving connector.

‘XT’ appears in the kit catalog number to identify a circuit board kit that

contains dielectric grease on connectors. Greased connectors are always

covered on new kits.

To be sure that edge connectors on circuit boards with XT maintain corrosion

resistance, do the following:

• Do not touch or remove the dielectric grease from the circuit-board edge

connectors. See Protective Cover Removal from Circuit Boards with

Dielectric Grease on page 17 for more information.

• Inspect and clean receiving connectors, if necessary, before you install a

new or existing circuit board. See Inspect and Clean Circuit Board

Connectors on page 18 for details.

• If the grease on a circuit board edge connector becomes contaminated or

the edge connector becomes exposed, see Apply Dielectric Grease to an

Edge Connector on page 18.

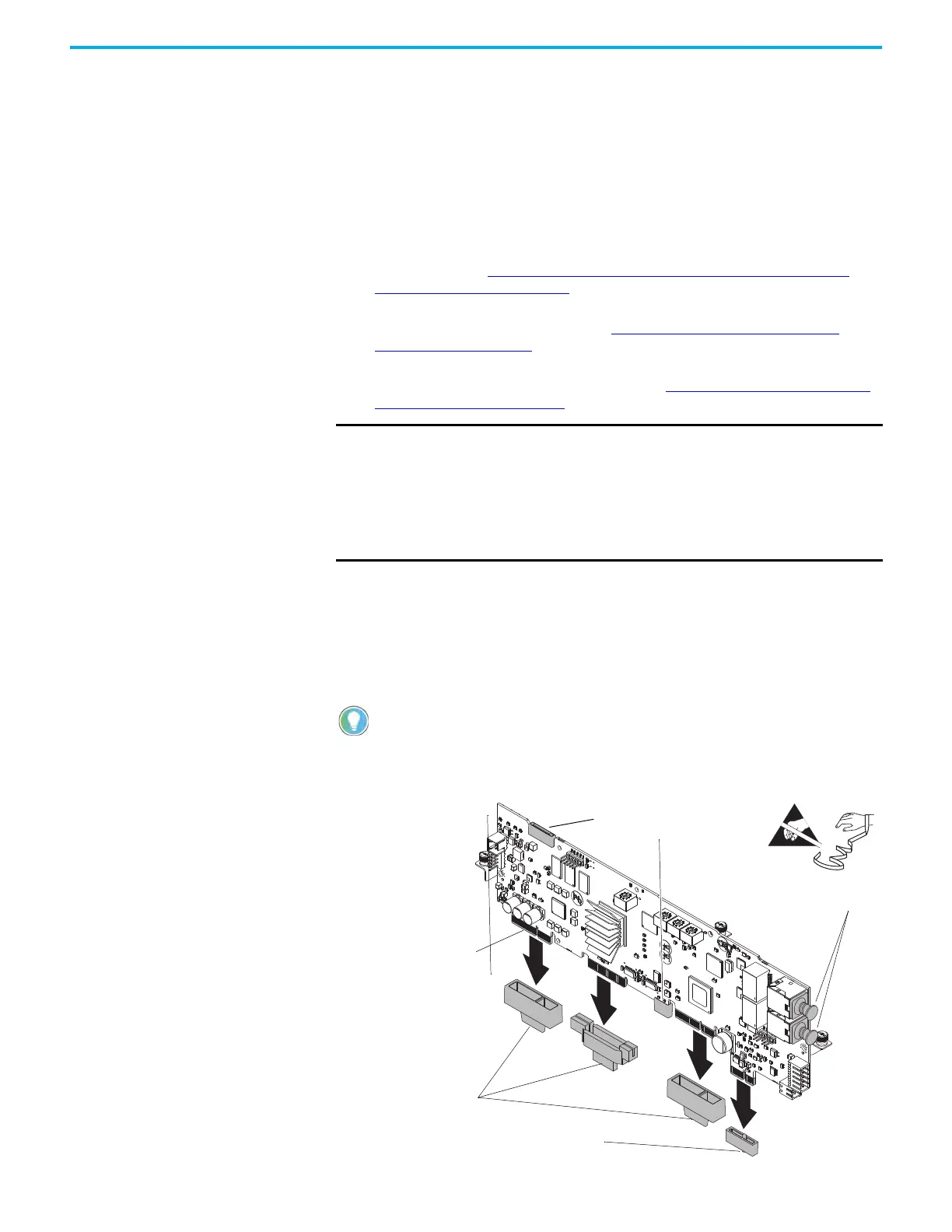

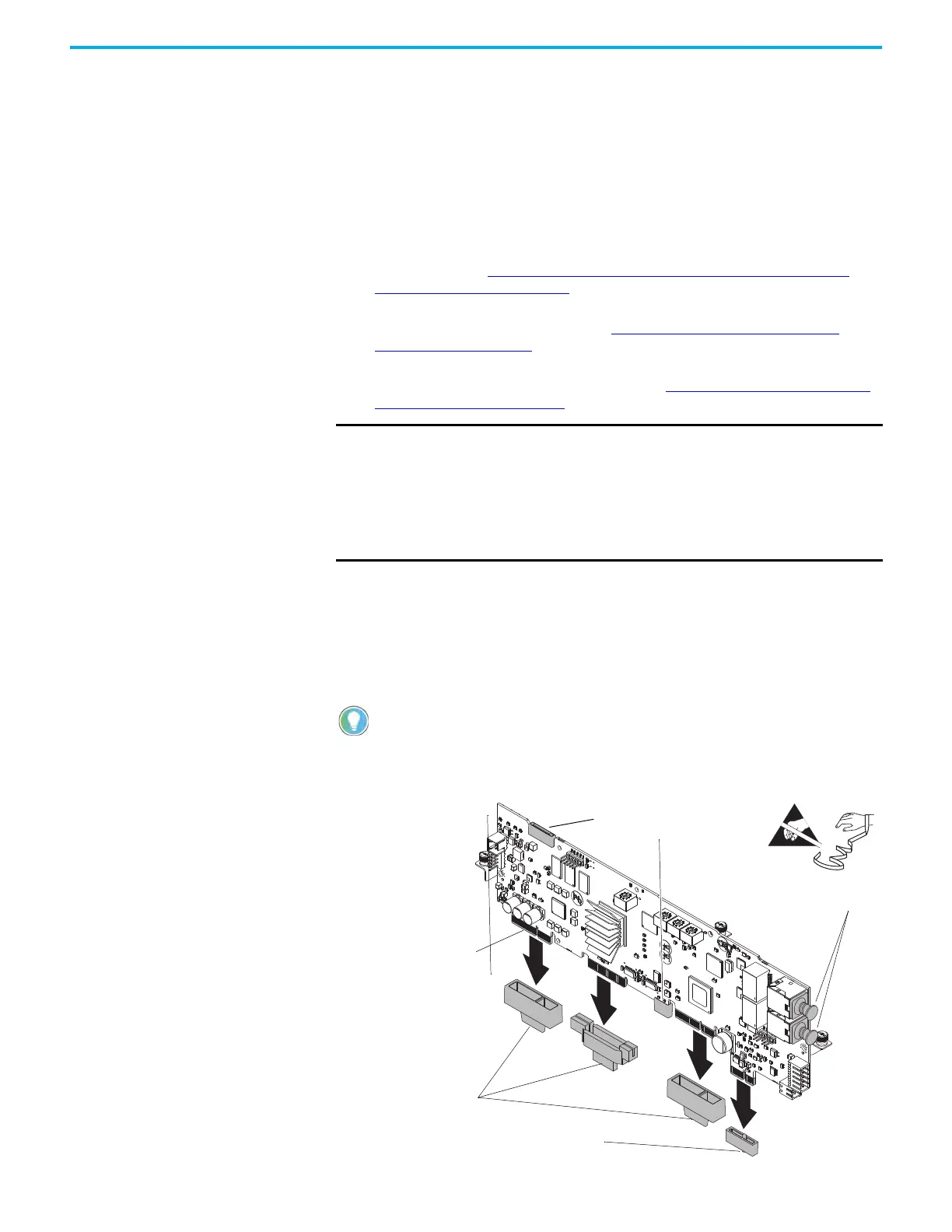

Protective Cover Removal from Circuit Boards with Dielectric Grease

When you install a new circuit board with dielectric grease on the edge

connectors, by holding the protective cover only, carefully remove the covers

from the edge connectors on the circuit board. Do not allow the edge

connectors to contact surfaces other than the receiving connector.

Figure 5 - Circuit Board with Protective Covers and Connectors with Dielectric Grease Example

IMPORTANT Edge connectors on circuit boards that are contained in renewal kits with

XT contain dielectric grease.

• Do not touch or remove the dielectric grease from circuit board edge con-

nectors. A non-greased edge connector can lead to corrosion.

• Do not allow the grease on the edge connectors to become contaminated

with any form of debris or particulate matter. Debris or particulate matter

on a greased connector can lead to premature failure of the circuit board.

It is highly recommended that you do not pull the circuit board edge connectors out of

the receiving connectors after it has been fully inserted and seated. Removing the cir-

cuit board after it has been seated can displace the dielectric grease on the edge con-

nectors.

Hold Protective Cover by Tab.

Remove Only when Used

Dielectric Grease on Connectors

(Grease is Translucent - Shown

Shaded for Example Only)

Main Control Circuit Board Shown

Remove Only when a Torque

Accuracy Module is Installed.

Do Not Remove these Protective Covers

(for Factory User Only).

Remove Only when EtherNet/IP™

Cables are Installed.

Loading...

Loading...