Commissioning

5.6 Commissioning in speed control mode (S)

SINAMICS V90, SIMOTICS S-1FL6

184 Operating Instructions, 04/2019, A5E36037884-007

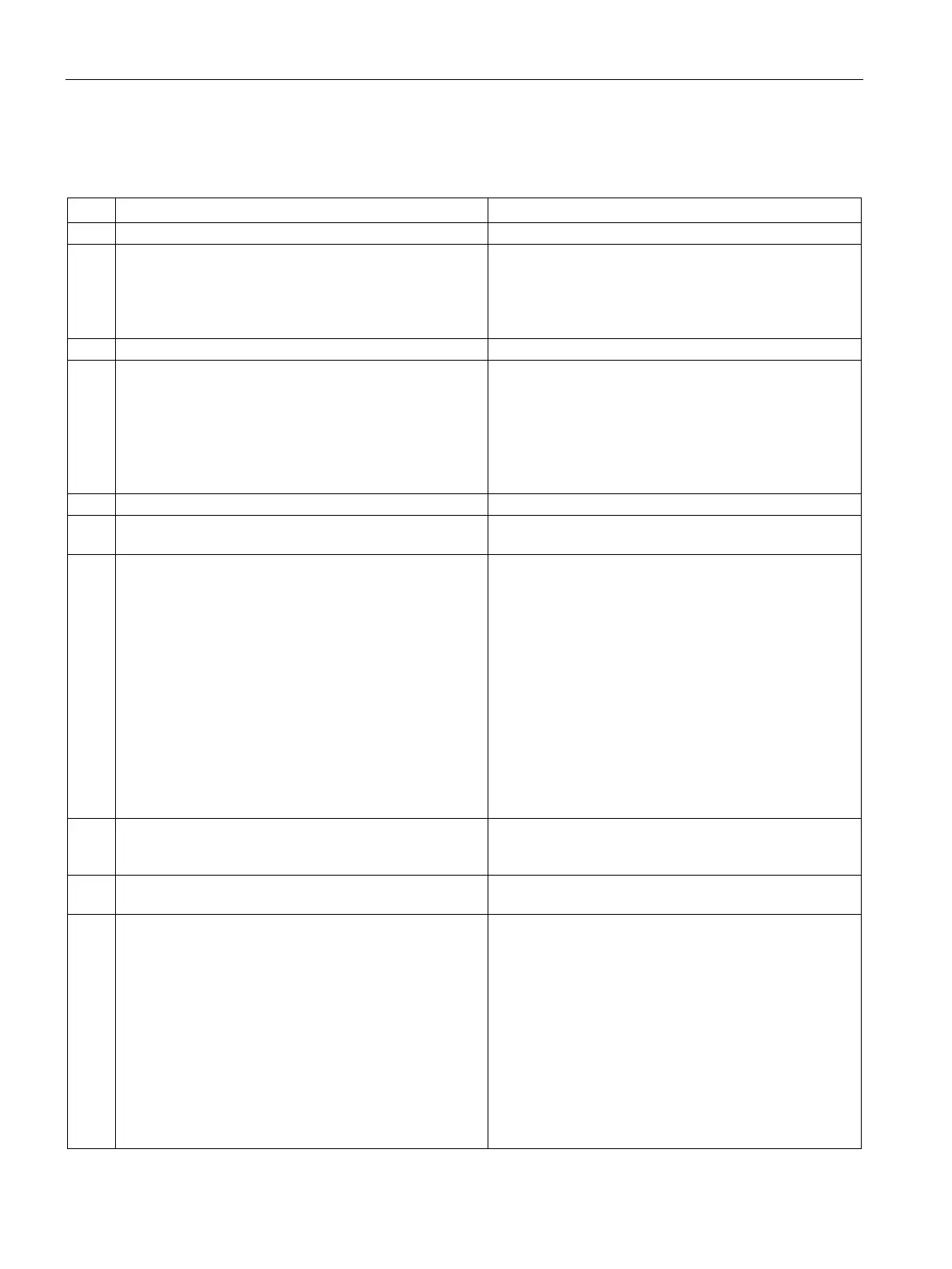

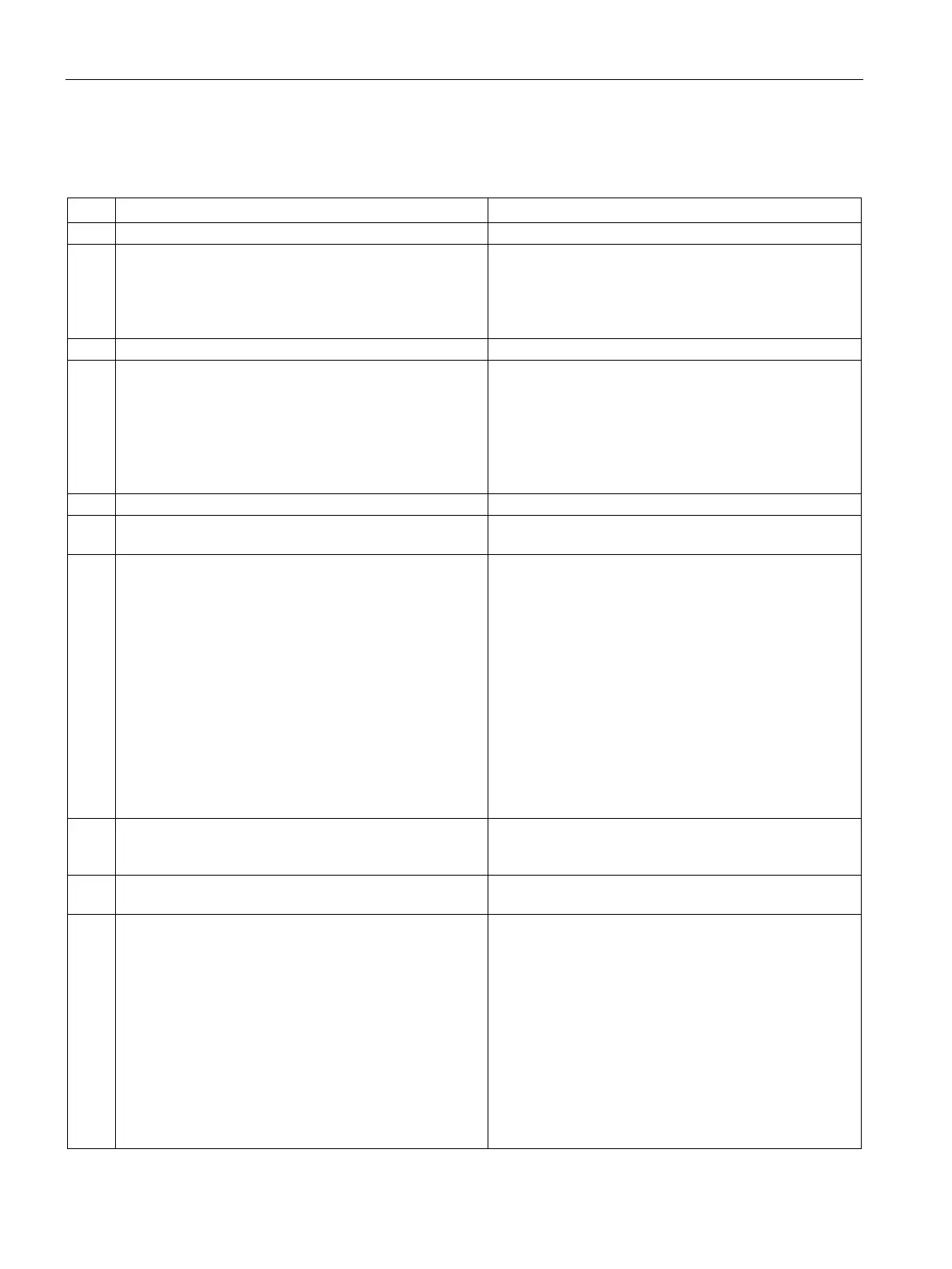

Commissioning in speed control mode (S)

Switch off the line supply.

Power off the servo drive and connect it to the controller

(for example, SIMATIC S7-200 SMART) with the signal

cable.

The digital signals CWL, CCWL and EMGS must be

kept at high level (1) to ensure normal operation.

Refer to "Standard application wiring (factory setting)

(Page 136)" and "Connection examples with PLCs

Switch on the 24 VDC power supply.

4 Check the servo motor type.

• If the servo motor has an incremental encoder, input

the motor ID (p29000).

• If the servo motor has an absolute encoder, the

servo drive can identify the servo motor automatical-

ly.

Fault

occurs when the servo motor is not identi-

fied.

You can find the motor ID from the motor rating plate.

Go to "Motor components (Page 30)" for detailed de-

scriptions about motor rating plate.

Refer to "Basic operations (Page 195)" for information

about how to change a parameter with the BOP.

Switch to the speed control mode by setting p29003 = 2.

Refer to "Compound controls (Page 209)".

6 Save the parameter and restart the servo drive to apply

the setting of the speed control mode.

Configure speed setpoint.

You can select the external analog speed setpoint or

one of seven fixed speed setpoints by configuring the

digital signals SPD3, SPD2 and SPD1.

SPD3 : SPD2 : SPD1

0 : 0 : 0: external analog speed setpoint (analog input 1)

0 : 0 : 1: fixed speed setpoint 1 (p1001)

0 : 1 : 0: fixed speed setpoint 2 (p1002)

0 : 1 : 1: fixed speed setpoint 3 (p1003)

1 : 0 : 0: fixed speed setpoint 4 (p1004)

1 : 0 : 1: fixed speed setpoint 5 (p1005)

1 : 1 : 0: fixed speed setpoint 6 (p1006)

1 : 1 : 1: fixed speed setpoint 7 (p1007)

Refer to "Configuring speed setpoint (Page 256)".

If the external analog speed setpoint is used, configure

the maximum analog speed setpoint corresponding to

10 V by setting parameter p29060.

9 Set the torque limitation and speed limitation. Refer to "Torque limit (Page 259)" and "Speed limit

Configure necessary digital input signals by setting the

following parameters:

• p29301[2]: DI1

• p29302[2]: DI2

• p29303[2]: DI3

• p29304[2]: DI4

• p29305[2]: DI5

• p29306[2]: DI6

• p29307[2]: DI7

• p29308[2]: DI8

The factory settings are:

• p29301[2]: 1 (SON)

• p29302[2]: 2 (RESET)

• p29303[2]: 3 (CWL)

• p29304[2]: 4 (CCWL)

• p29305[2]: 12 (CWE)

• p29306[2]: 13 (CCWE)

• p29307[2]: 15 (SPD1)

• p29308[2]: 16 (SPD2)

Refer to "Digital inputs/outputs (DIs/DOs) (Page 122)".

Loading...

Loading...