Cycles

9.11 Oblique plunge-cutting – CYCLE413

Cylindrical grinding

Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

185

9.11 Oblique plunge-cutting – CYCLE413

Programming

CYCLE413(N_SITZ, X_SOLL, Z_SCH, WIN, B_ART, A_LU, A_SR, A_SL, A_FSL, F_SR,

F_SL, F_FSL, TIME, MZ, KS, F_KS, UWERK)

Parameter

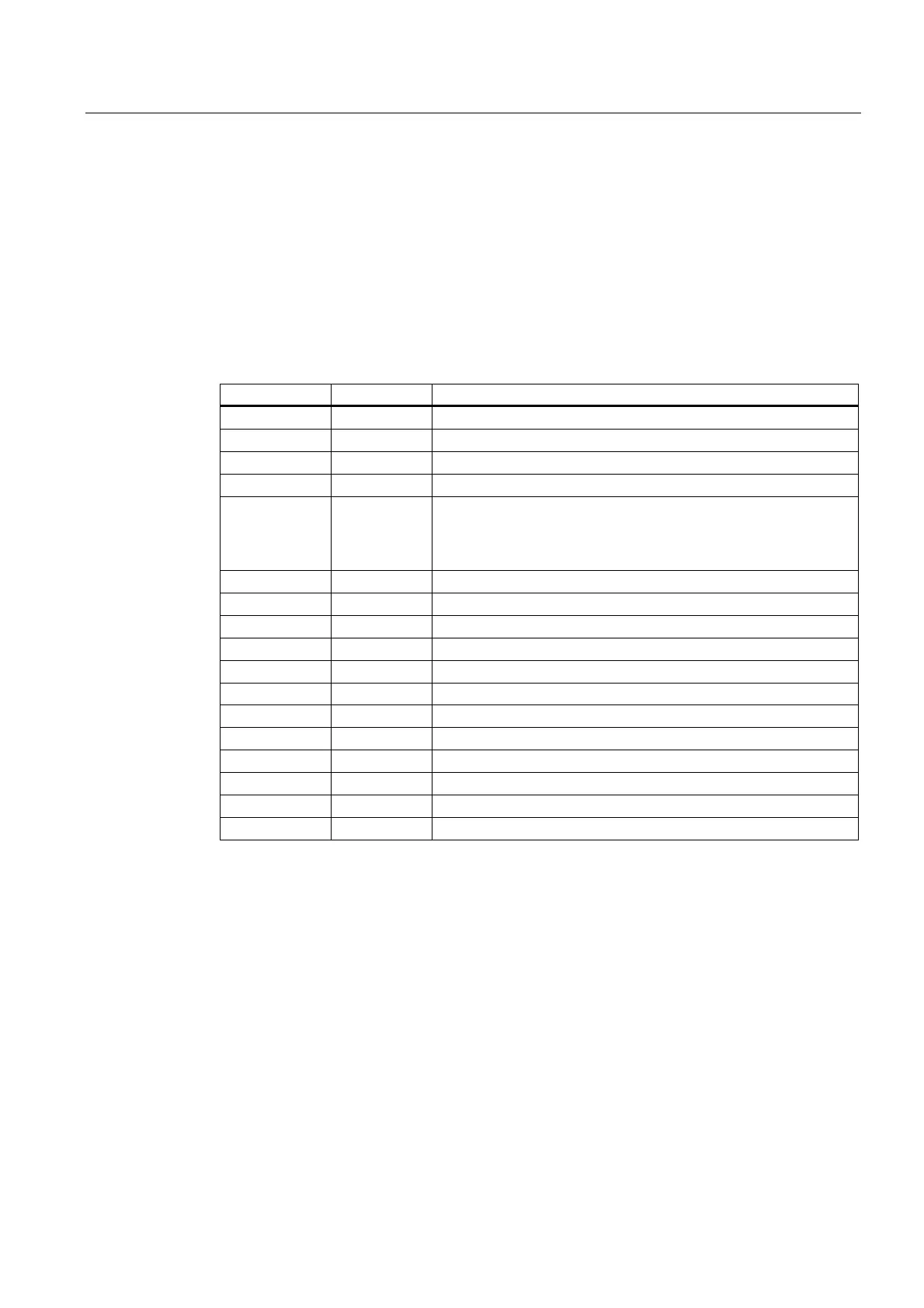

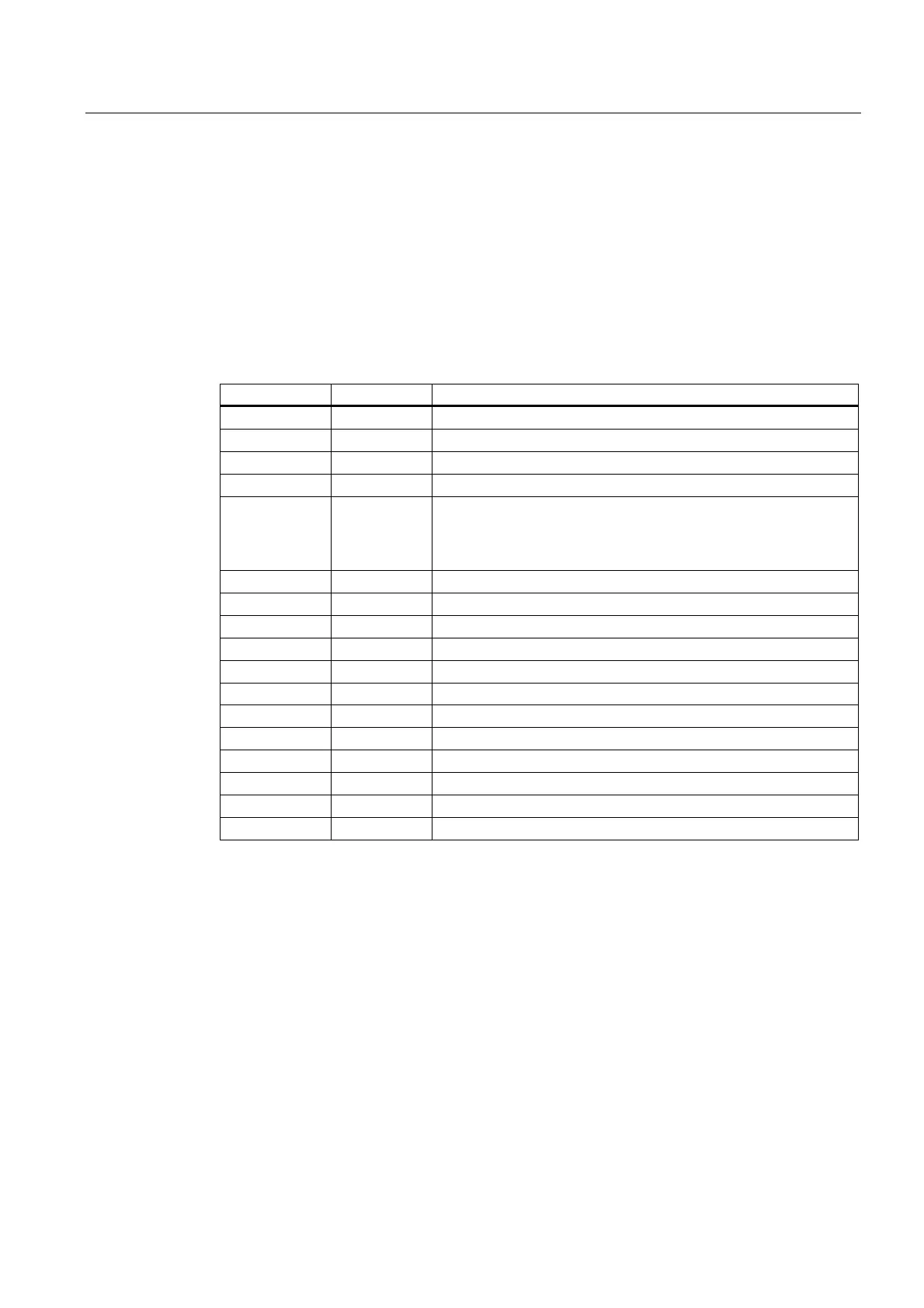

Table 9- 7 Parameters of CYCLE413

Parameter Data type Meaning

N_SITZ INT Seat number

X_SOLL REAL Setpoint diameter (abs.)

Z_SCH REAL Shoulder dimension in Z (abs.)

WIN REAL Oblique plunge-cut angle (incr.)

B_ART INT Machining type:

1=roughing

2=finishing+fine-finishing

3=roughing+finishing+fine-finishing

A_LU REAL Air allowance (incr.)

A_SR REAL Roughing allowance (incr.)

A_SL REAL Finishing allowance (incr.)

A_FSL REAL Fine-finishing allowance (incr.)

F_SR REAL Feedrate for roughing

F_SL REAL Feedrate for finishing

F_FSL REAL Feedrate for fine-finishing

TIME REAL Sparking-out time (s)

MZ INT Measurement control Yes=1/No=0

KS INT Acoustic emission sensor Yes=1/No=0

F_KS REAL Feedrate for air grinding [mm/min]

UWERK REAL Workpiece peripheral speed [m/min]

Function

The oblique plunge-cutting cycle is used for machining a cylindrical seat or for machining a

shoulder and a diameter simultaneously. The wheel width must be greater than or equal to

the width of the seat to be machined.

An acoustic emission sensor can be used to bridge the distance between the starting point

and the actual workpiece surface within an optimum time by sparking.

The plunge-cutting direction is determind by means of the angle.

● Negative angle → plunge-cutting motion in Z+ direction

● Positive angle → plunge-cutting motion in Z- direction

To check the workpieces for their finished dimension and to switch the individual feedrates in

the various technological sections, a measurement control (caliper) which is already in use

during the machining can be used.

Loading...

Loading...