Appendix

A.2 Parameter tables of the tool data

Cylindrical grinding

380 Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

A.2 Parameter tables of the tool data

The following parameters, operated from the HMI, are available for the tool offsets.

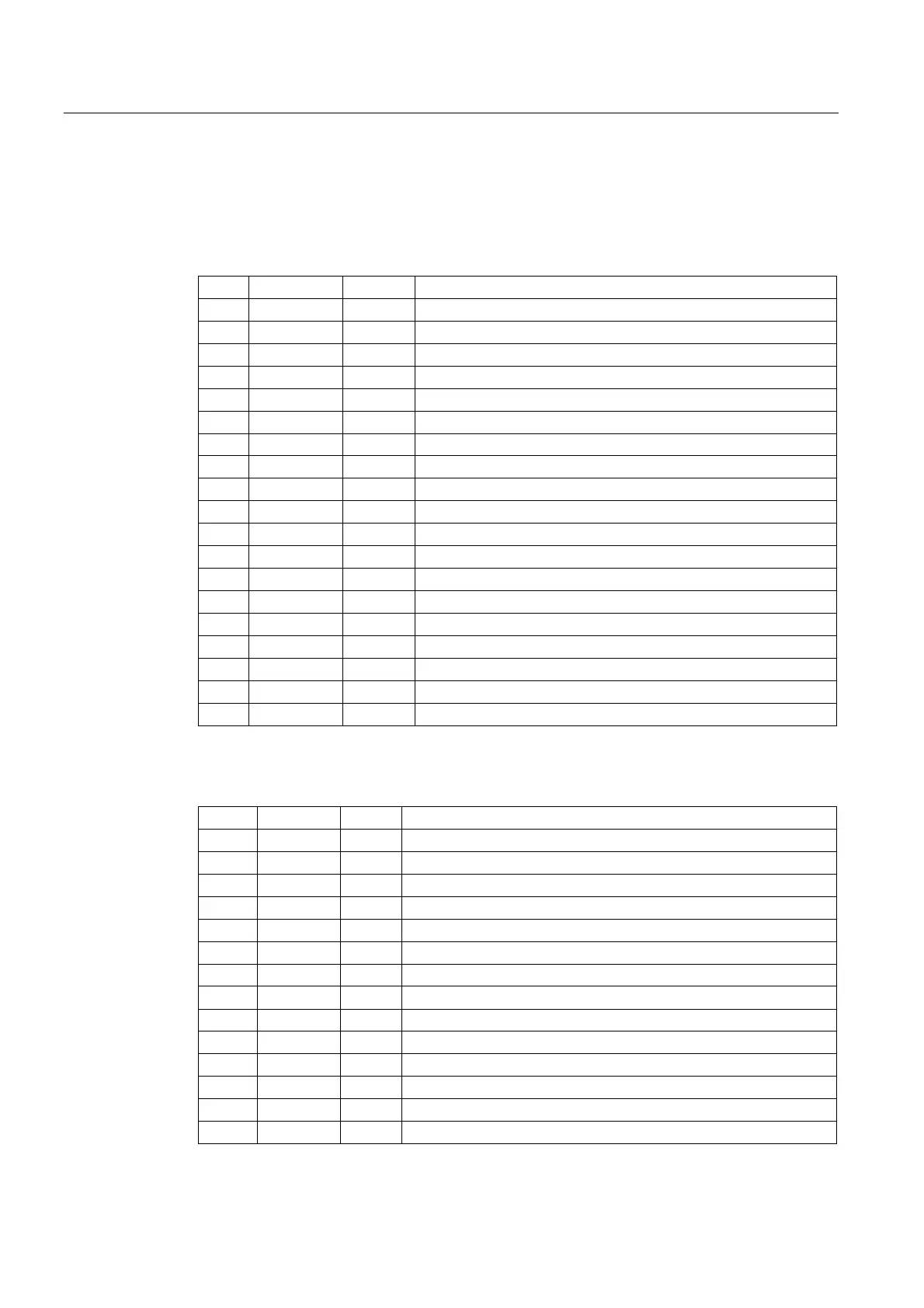

Table A- 1 Grinding wheel data, x=[1...n] y=[1...6]

Tx TPG1 INT Spindle number

Tx TPG2 INT Concatenation rule = 0

Tx TPG3 REAL Min. wheel diameter

Tx TPG4 REAL Min. wheel width

Tx TPG5 REAL Current grinding wheel width

Tx TPG6 REAL Maximum speed

Tx TPG7 REAL Maximum GWPS

Tx TPG8 REAL Angle of inclined wheel

Tx TPG9 INT Parameter no. for radius calculation

Tx TPC1 REAL Wheel type (vertical, inclined, free)

Tx TPC2 REAL Amount of crown

Tx TPC3 REAL Dressing amount

Tx TPC4 REAL Cylindric compensation

Tx TPC5 REAL GWPS

Tx TPC6 REAL GWPS ratio

Tx TPC7 REAL Bypassing strategy (obstacle diameter)

Tx TPC8 REAL Basic cutting edge for dressing contour

Tx TPC9 REAL X shift

Tx TPC10 REAL Z shift

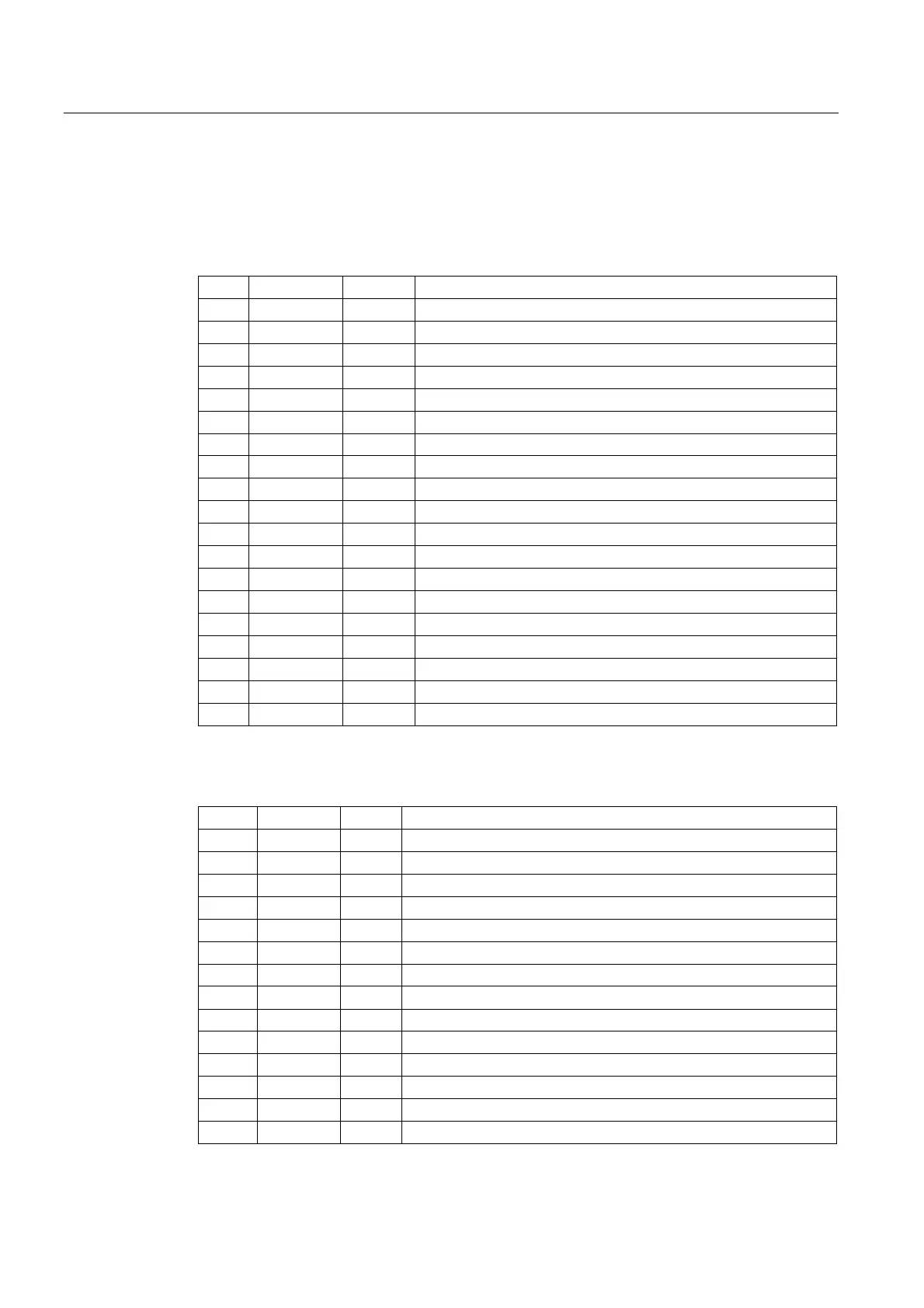

Table A- 2 1. Cutting edge 2. Cutting edge for left/right wheel edge for grinding wheel

Tx Dy DP1 INT Tool type=403

Tx Dy DP2 INT Cutting edge position (1...9)

Tx Dy DP3 REAL D - Diameter of the new wheel

Tx Dy DP4 REAL L - Distance of the wheel reference point

Tx Dy DP5 REAL (reserved, length 3)

Tx Dy DP6 REAL R - Tool nose radius

Tx Dy DP7 REAL Dressing amount (µm) left/right

Tx Dy DP8 REAL Dresser wear X (µm) left/right

Tx Dy DP9 REAL Dresser wear Z (µm) left/right

Tx Dy DP10 REAL Path feedrate (mm/rev), left/right

Tx Dy DP11 REAL Path feedrate X (mm/rev), left/right

Tx Dy DP12 REAL dD - Change in diameter (dressing amount X)

Tx Dy DP13 REAL dL - Change in distance (dressing amount Z)

Tx Dy DP14 REAL (Length 3)

Tx Dy DP15 REAL dR - Change in tool nose radius (radius wear)

Loading...

Loading...