Cylindrical grinding

Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

377

Appendix

A

A.1 User data

The user data is internally processed in the grinding cycles. They are stored in the program

manager of the control system (in the directory \DEF) as a definition file and remain stored

even when the control is switched off and on.

Description of the user data

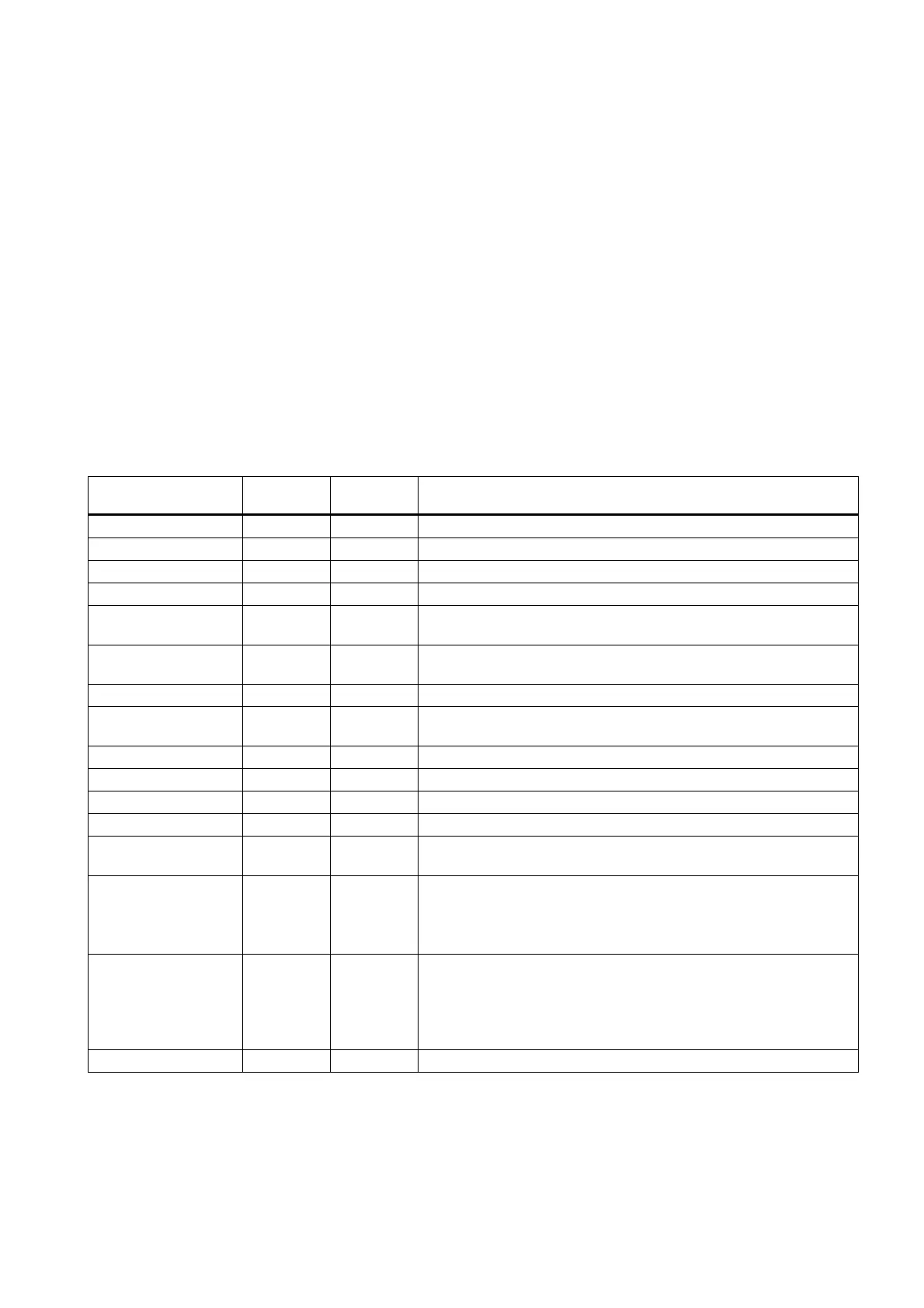

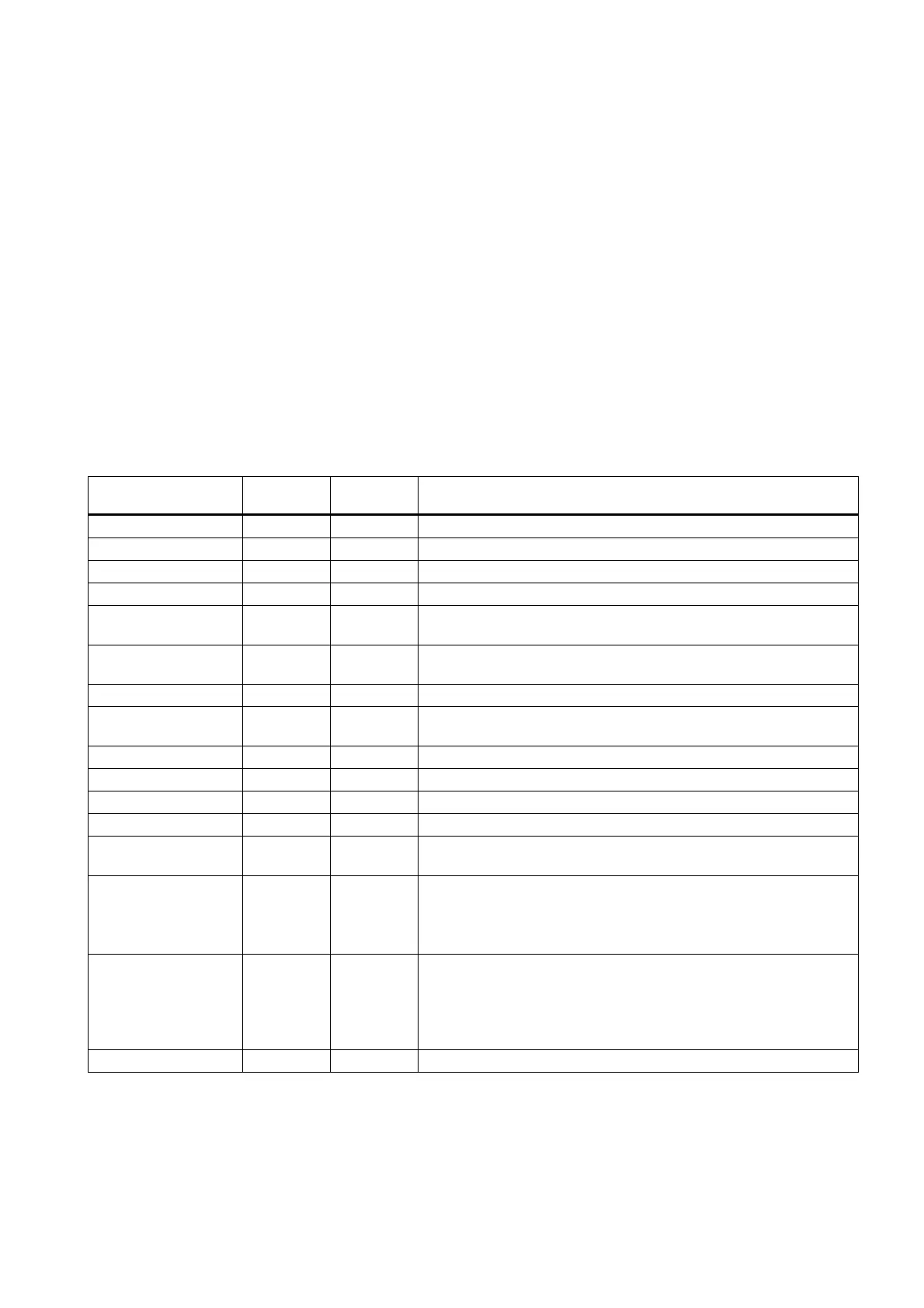

The parameters included in the definition files are described as follows:

Name Type Default

Value

Description

_GC_LERF REAL Detected longitudinal position when setting up

_GC_LVER REAL Offset during longitudinal position sensing

_GC_LNPVZ REAL Initial Z zero shift during calibration

_GC_LXPOS REAL X position while longiitudinal position is sensed

_GC_PARR[20] REAL REAL type parameters for inter cycle as well as cycle HMI

communication

_GC_PAR[0] INT 0/1 Selection of the type of plunging feedrate in mm/min / specific cutting

volumes

_GC_PAR[1] INT 0/1 Selection of the longitudinal grinding feedrate in mm/min or mm/rev

_GC_PARI[20] INT INTEGER type parameters for inter cycle as well as cycle HMI

communication

_GC_SYNC INT 0 HMI synchronisation parameters

_GC_SYNC INIRE INT 0 Delete synchronisation parameters on reset

_GC_WPC INT 0 Workpiece counter for dressing interval

_GC_BAXIS STRING[10] Name of the swivel axis

_GC_DNUM INT 7 D number for the 1st data block of dressing data in the tool

compensation

_GC_KNVX INT 0 There it is defined how the detected offset will be taken into account

in X:

0 ... Through work offset (NV)

1 ... as wheel diameter offset

_GC_KORR

INT 0 Selection of measurement control compensation computation

0 ... Compensation of the setpoint-actual value difference in the wear

of the wheel / dresser

1 ... Compensation of the setpoint-actual value difference in WO in X

2 ... No compensation of the setpoint-actual value difference

_GC_MF[20] INT M command number

Loading...

Loading...