Programming

10.2 Positional data

Cylindrical grinding

242 Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

G700/G710 however, also affects the feedrate F (inch/min, inch/rev. or mm/min, mm/rev.).

Note

Cycles for external cylindrical grinding only support metric dimensions.

10.2.4 Radius / diameter dimensions: DIAMOF, DIAMON, DIAM90

Functionality

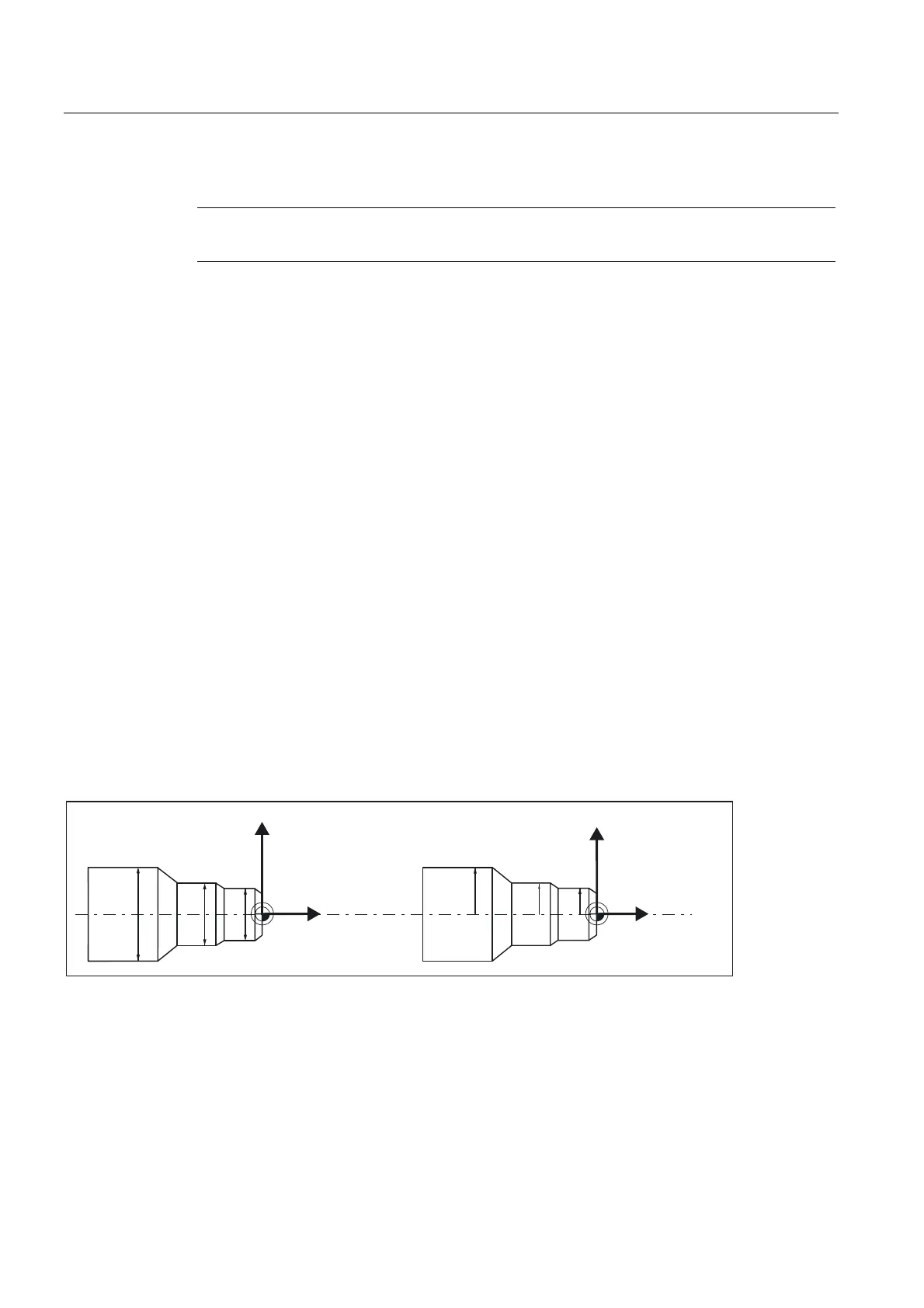

For machining parts, the positional data for the X–axis (transverse axis) is programmed as

diameter dimensioning. When necessary, it is possible to switch to radius dimensioning in

the program.

DIAMOF or DIAMON assesses the end point specification for the X axis as radius or

diameter dimensioning. The actual value appears in the display accordingly for the

workpiece coordinate system.

For DIAM90, irrespective of the traversing method (G90/G91), the actual value of the

transverse axis is always displayed as a diameter. This also applies to reading of actual

values in the workpiece coordinate system with MEAS, MEAW, $P_EP[x] and $AA_IW[x].

Programming

DIAMOF ; Radius dimensioning

DIAMON ; Diameter dimensioning

DIAM90 ; diameter dimensioning for G90, radius dimensioning for G91

5

5

5

'LDPHWHUGLPHQVLRQV

',$021

7UDQVYHUVHD[LV

5DGLXVGLPHQVLRQLQJ

',$02)

7UDQVYHUVHD[LV

/RQJLWXGLQDOD[LV /RQJLWXGLQDOD[LV

;

;

:

:

= =

Figure 10-4 Diameter and radius dimensioning for the transverse axis

Loading...

Loading...