Cycles

9.15 General workpiece data – CYCLE420

Cylindrical grinding

Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

203

9.15 General workpiece data – CYCLE420

Programming

CYCLE420(X_SOLL, X_AB, Z_AB_L, Z_AB_R, F_DL_AB, F_BL_AB, F_DR_AB, F_BR_AB,

F_Z_AB, FFW, USCH, UWERK, Z_LPOS, Z_SCH, ZSTW, F_Z_MESS, N_ABR, N_AWST)

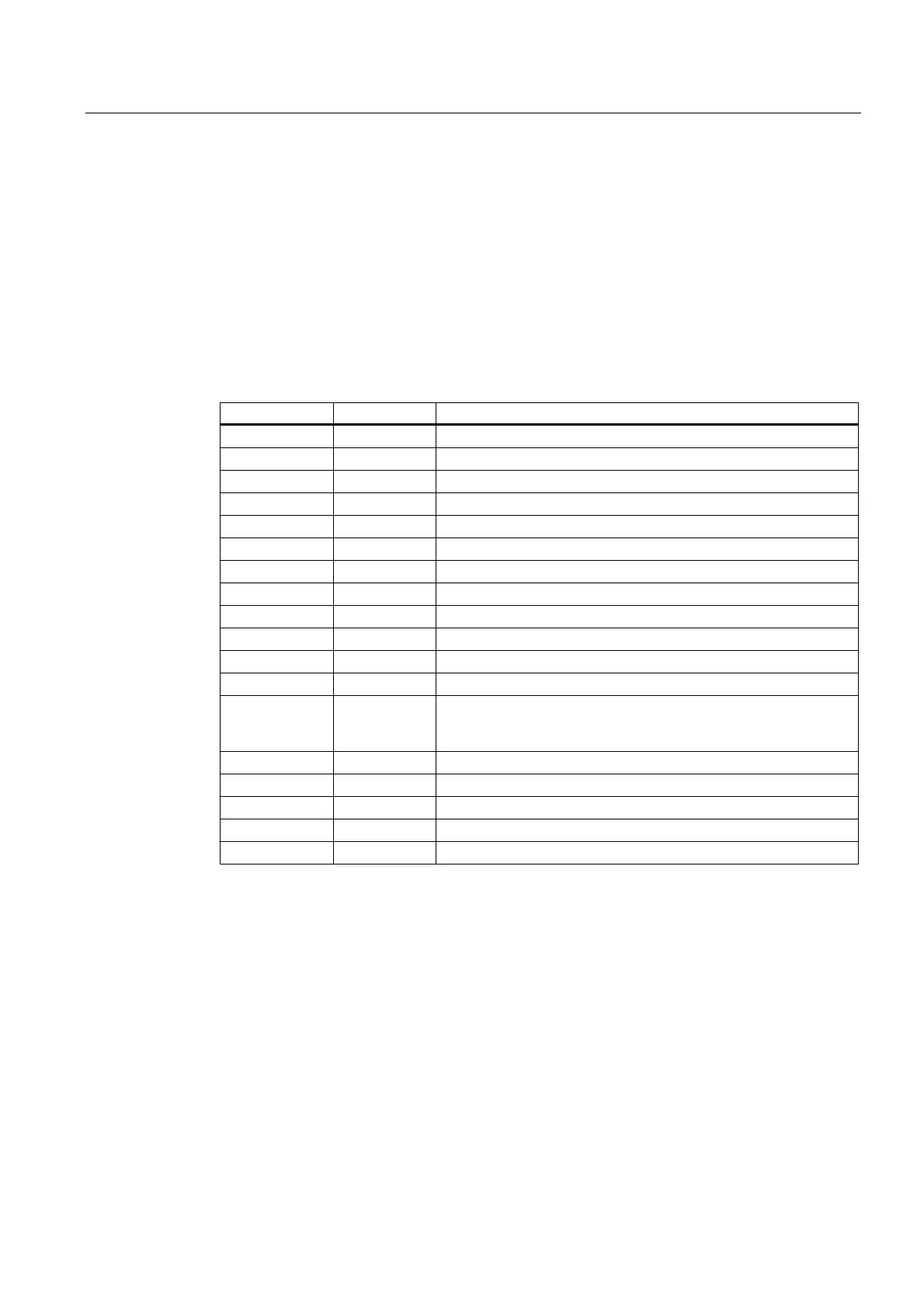

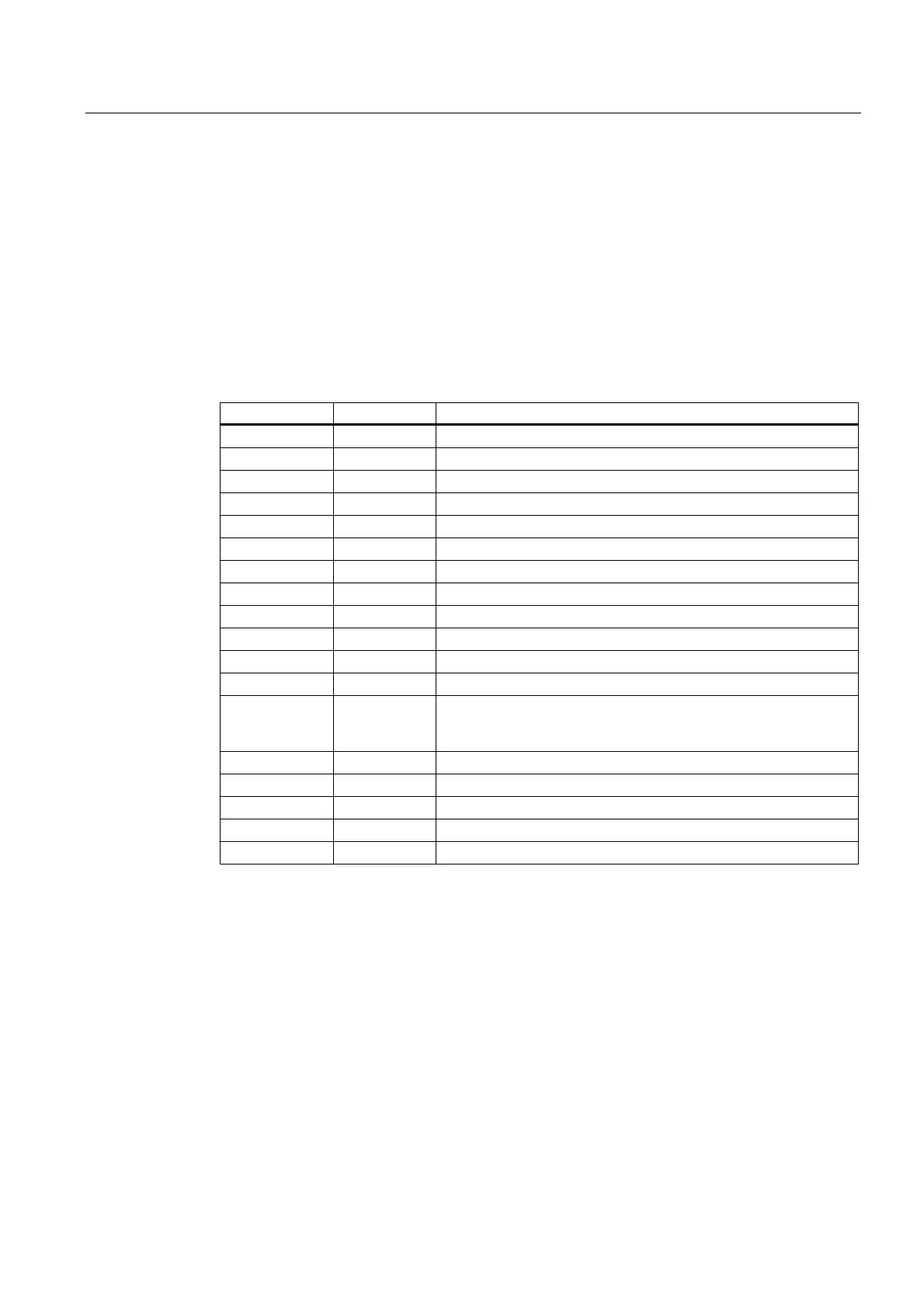

Parameter

Table 9- 12 Parameters of CYCLE420

Parameter Data type Meaning

X_SOLL REAL Diameter for workpiece peripheral speed (WUG)

X_AB REAL Dressing amount in X (incr.)

Z_AB_L REAL Dressing amount in Z, left/front (incr.)

Z_AB_R REAL Dressing amount in Z, right/rear (incr.)

F_DL_AB REAL Feedrate in the diameter direction, left

F_BL_AB REAL Path feedrate, left

F_DR_AB REAL Feedrate in the diameter direction, right

F_BR_AB REAL Path feedrate, right

F_Z_AB REAL Dressing feedrate in Z

FFW REAL Retraction travel (incr.)

USCH REAL Wheel peripheral speed [m/s]

UWERK REAL Workpiece peripheral speed [m/min]

Z_LPOS INT Longitudinal position,

0 = no longitudinal positioning

-1 = shoulder left

Z_SCH REAL Z dimension for shoulder

ZSTW REAL Infeed travel for probe (incr.)

F_Z_MESS REAL Measuring feedrate

N_ABR INT Number of dressing strokes

N_AWST INT Number of workpieces before dressing

Function

Typically, general workpiece data are valid for each workpiece seat. Hence the cycle must

be called at the beginning of a machining program and after each diameter or change to the

tool peripheral speed.

For dressing prior to the nth workpiece, workpiece counting is performed in the GC_WPC

parameter for each wheel. Dressing takes place whenever the counter can be divided by the

parameter N_AWST without a remainder.

This cycle processes the fine correction parameters for the X and Z axes.

Loading...

Loading...