Engine Mechanical: 1D-29

NOTE

To properly measure the oil clearance with

plastigauge, all gasket material must be

removed from fitting surfaces of cylinder

head and cover. Do not apply bond until after

the oil clearance has been determined.

• Tighten the camshaft journal holder bolts evenly and

diagonally to the specified torque.

Tightening torque

Cylinder head cover bolt : 10 N·m (1.0 kgf-m, 7.3

lb-ft)

NOTE

Do not rotate the camshafts with the

plastigauge in place.

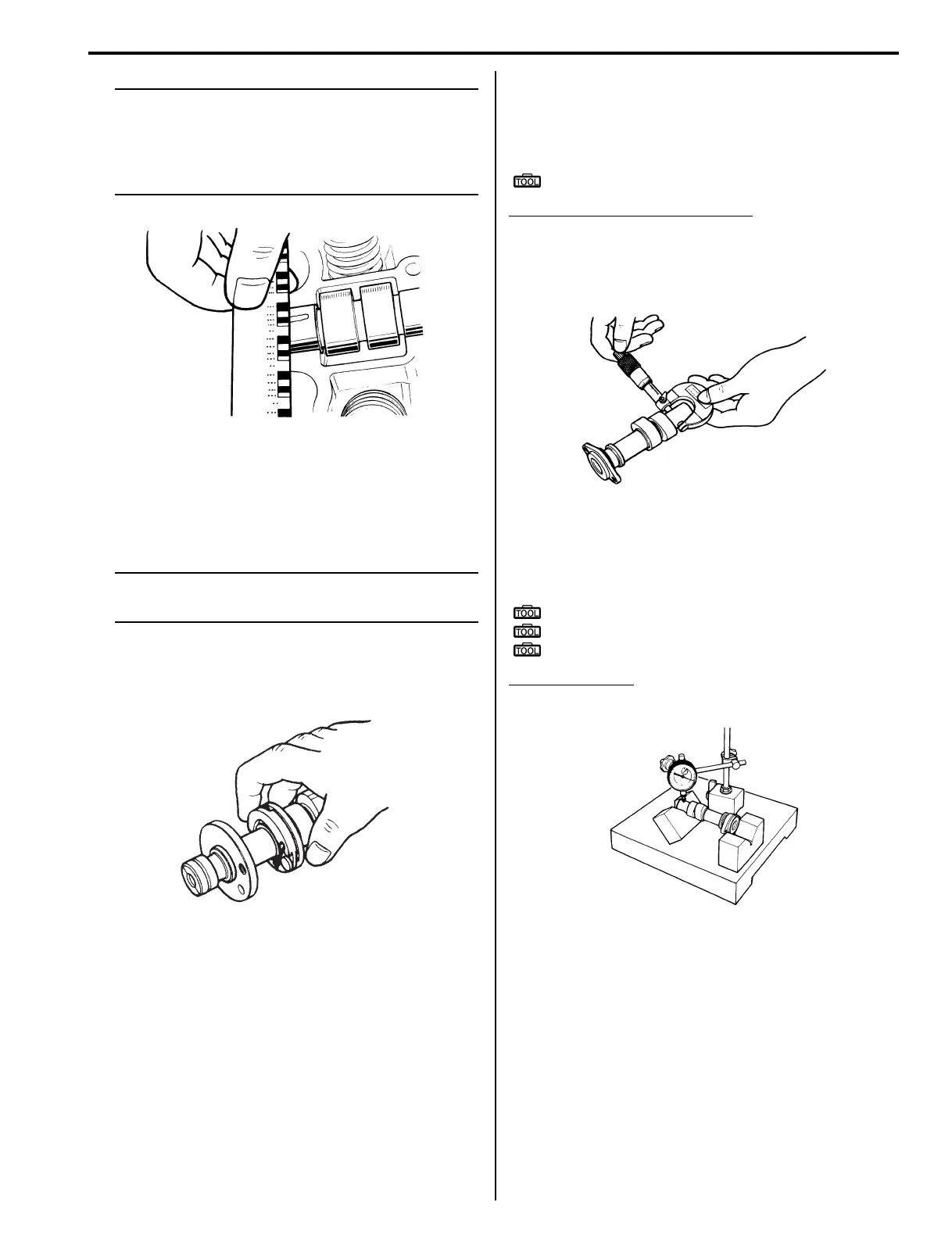

Remove the cylinder head cover, and read the width of

the compressed plastigauge with envelope scale. This

measurement should be taken at the widest part.

If the camshaft journal oil clearance exceeds the limit,

measure the outside diameter of the camshaft. Replace

either the cylinder head set or camshaft if it the

clearance is incorrect.

Special tool

: 09900–20205 (Micrometer (0 – 25 mm))

Camshaft journal O.D. (IN. & EX.)

Standard (Sprocket side): 21.959 – 21.980 mm

(0.8645 – 0.8654 in)

Standard (Other side): 17.466 – 17.484 mm (0.6876 –

0.6883 in)

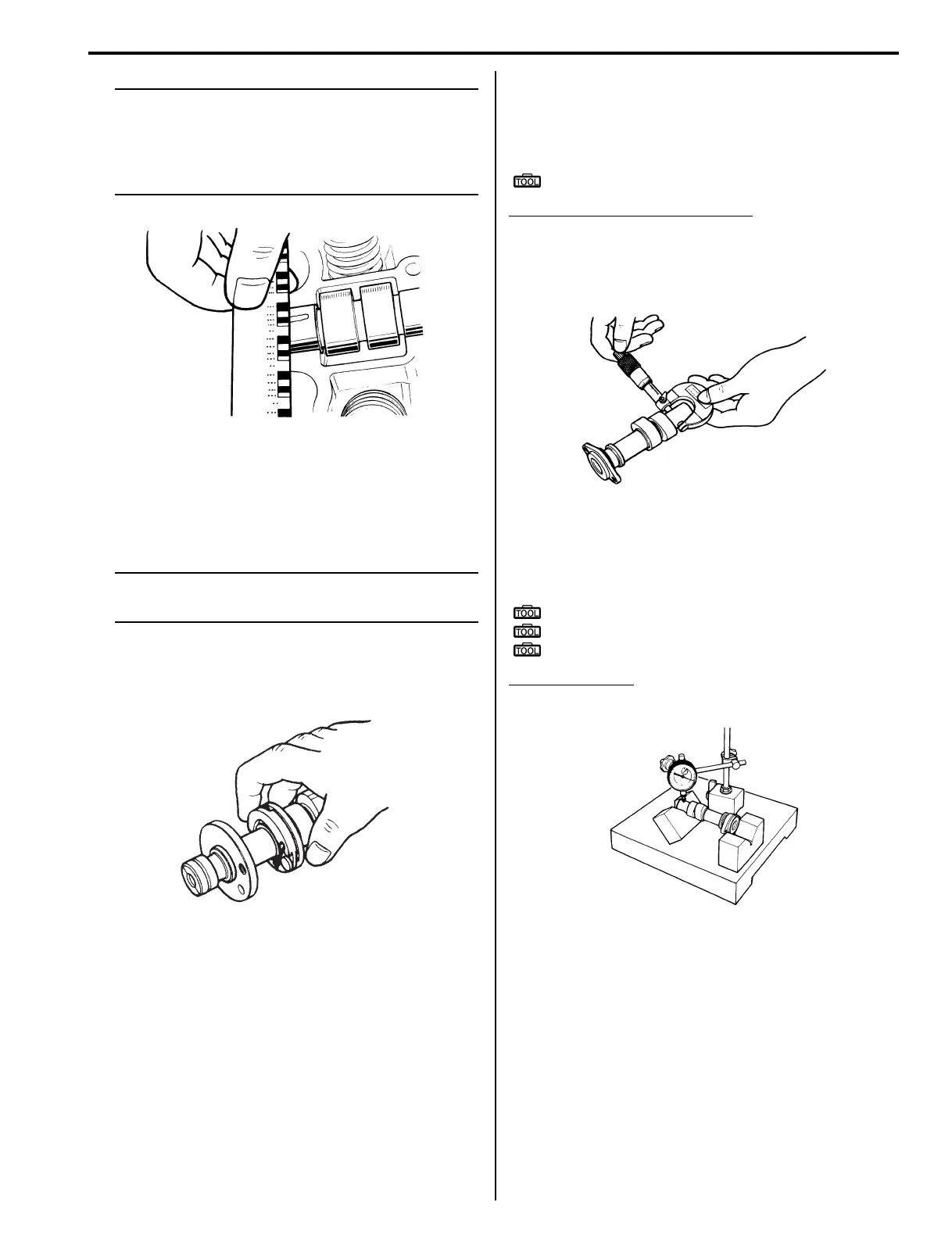

Camshaft Runout

Measure the runout with a dial gauge. Replace the

camshaft if the runout exceeds the limit.

Special tool

: 09900–20607 (Dial gauge (1/100 mm, 10 mm))

: 09900–20701 (Magnetic stand)

: 09900–21304 (V-block (100 mm))

Camshaft runout

Service limit: 0.10 mm (0.004 in)

I827H1140077-01

I827H1140078-01

I827H1140079-01

I827H1140080-01

Loading...

Loading...