1D-58 Engine Mechanical:

Conrod and Crankshaft Inspection

B827H11406035

Refer to “Engine Bottom Side Disassembly (Page 1D-

34)”.

Conrod Small End I.D.

Measure the conrod small end inside diameter with the

dial calipers.

If conrod small end inside diameter exceeds the service

limit, replace the conrod.

Special tool

(A): 09900–20605 (Dial calipers (1/100 mm, 10 –

34 mm))

Conrod small end I.D.

Service limit: 20.040 mm (0.7890 in)

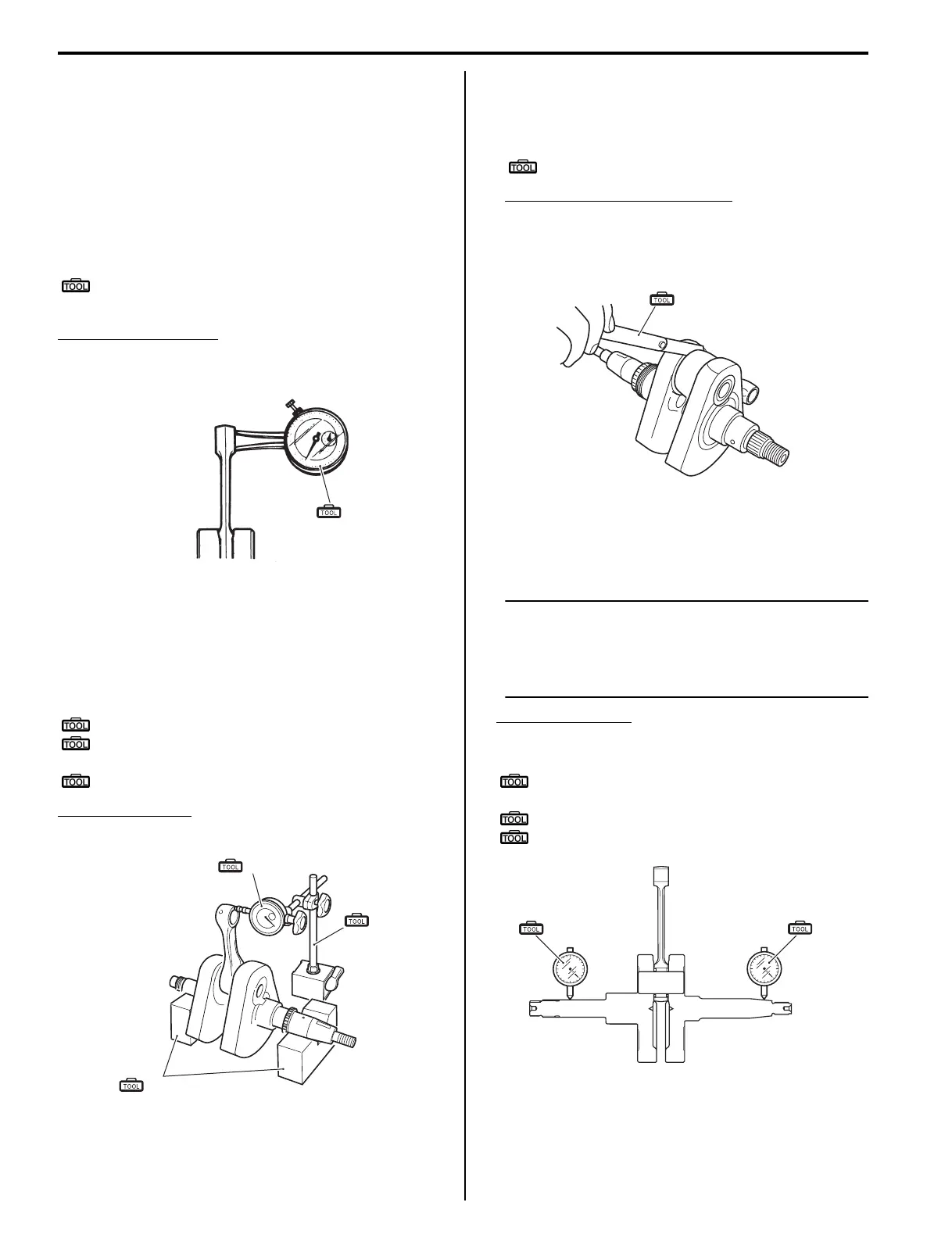

Conrod Deflection

Wear On the big end of the conrod can be estimated by

checking the movement of the small end of the rod. This

method can also check the extent of ware on the parts of

the conrod’s big end.

Special tool

(A): 09900–20701 (Magnetic stand)

(B): 09900–20607 (Dial gauge (1/100 mm, 10

mm))

(C): 09900–21304 (V-block (100 mm))

Conrod deflection

Service Limit: 3.0 mm (0.12 in)

Conrod Big End Side Clearance

1) Check the conrod big end side clearance with the

thickness gauge.

Special tool

(A): 09900–20803 (Thickness gauge)

Conrod big end side clearance

Service limit: 1.0 mm (0.04 in)

2) If the clearance exceeds the limit, replace the

crankshaft assembly and conrod with a new one.

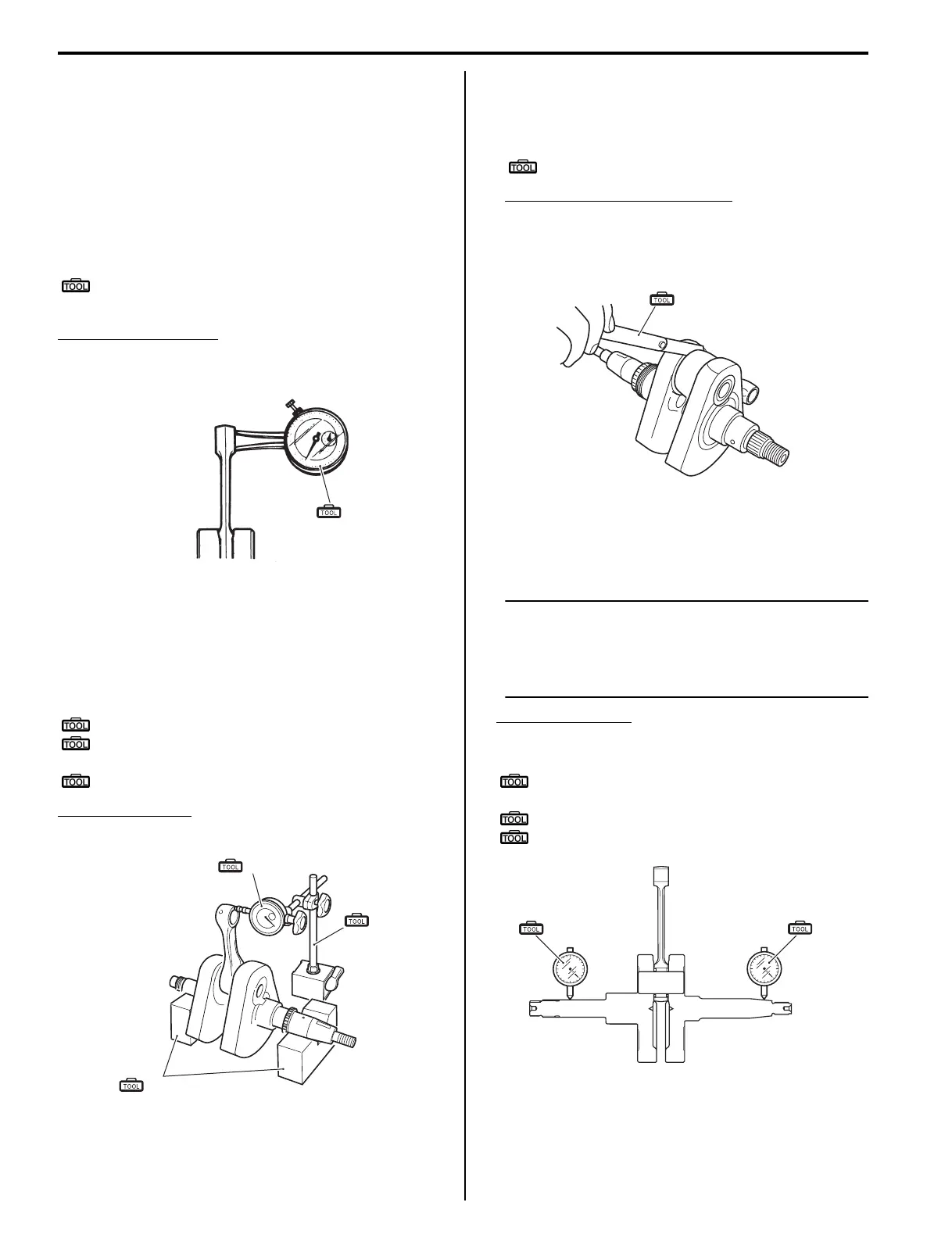

Crankshaft Runout

• Measure the crankshaft runout with V-blocks and dial

gauge.

NOTE

• Place the crankshaft onto the V-blocks so

that it becomes horizontally.

• Measure the runout from the tips of the

crankshaft.

Crankshaft runout

Service limit: 0.08 mm (0.003 in)

Special tool

(A): 09900–20607 (Dial gauge (1/100 mm, 10

mm))

: 09900–20701 (Magnetic stand)

: 09900–21304 (V-block (100 mm))

(A)

I831G1140292-02

(A)

(B)

(C)

I831G1140293-01

(A)

I831G1140294-01

(A)

(A)

I705H1140241-01

Loading...

Loading...