Engine Mechanical: 1D-9

Engine Assembly Installation

B827H11406014

Reinstall the engine in the reverse order of removal. Pay

attention to the following points:

NOTE

The engine mounting nuts are self-locking.

Once the nut has been removed, it is no

longer any use. Be sure to use new nuts, and

then tighten them to the specified torque.

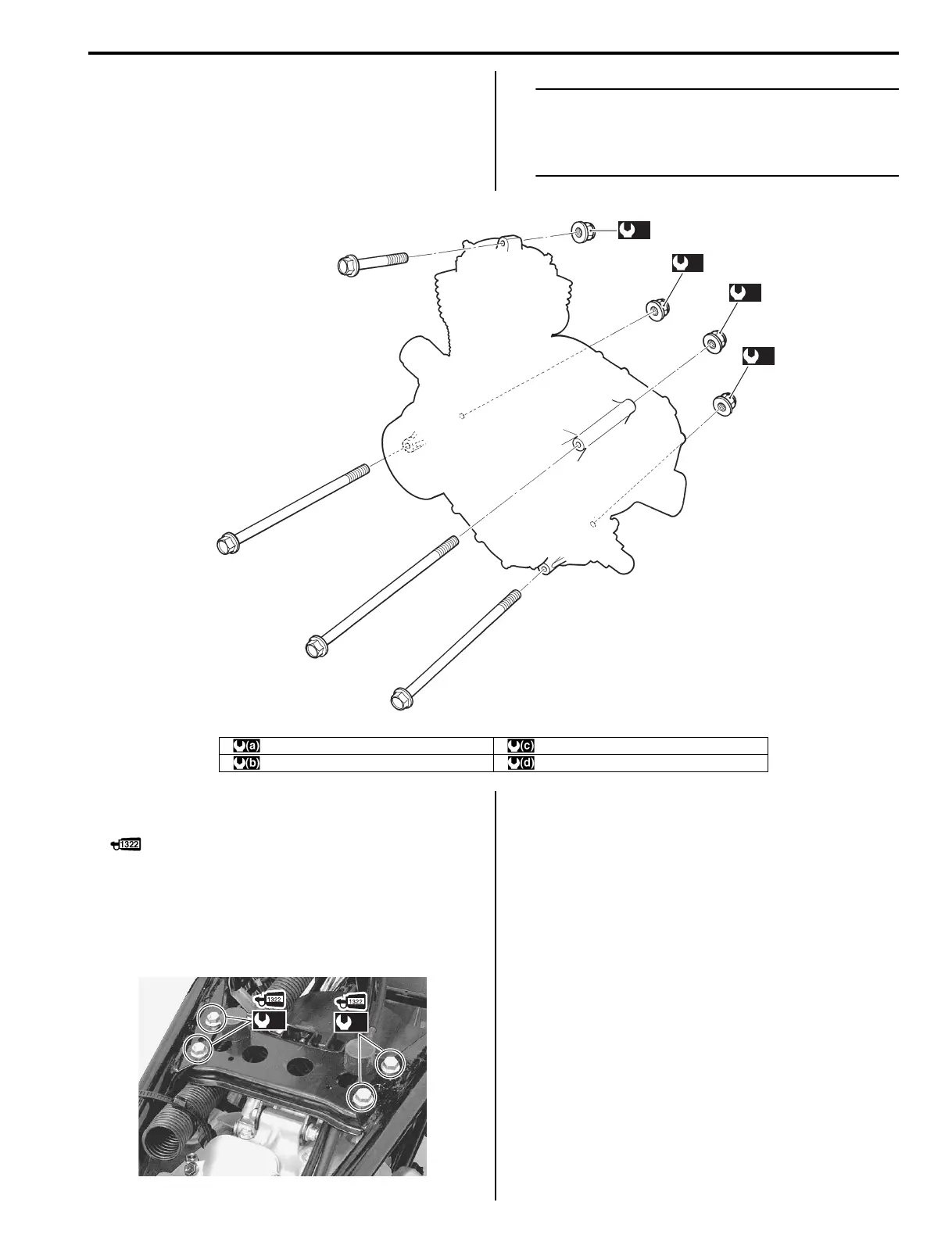

• Apply thread lock to the engine mounting bracket

bolts and tighten them to the specified torque.

: Thread lock cement 99000–32110

(THREAD LOCK CEMENT SUPER 1322 or

equivalent)

Tightening torque

Engine mounting bracket bolt (a): 28 N·m (2.8

kgf-m, 20.0 lb-ft)

• Install the front propeller shaft and front differential

assembly. Refer to “Front Drive (Differential)

Assembly Removal and Installation (LT-A400F, LT-

F400F) in Section 3B (Page 3B-4)”.

• Install the right footrest. Refer to “Footrest Removal

and Installation in Section 9E (Page 9E-2)”.

• Install the rear brake pedal. Refer to “Rear Brake

Pedal Removal and Installation in Section 4A

(Page 4A-12)”.

• Install the exhaust pipe and muffler. Refer to “Muffler /

Exhaust Pipe Removal and Installation in Section 1K

(Page 1K-2)”.

• Install the carburetor. Refer to “Carburetor Assembly

Removal and Installation in Section 1G (Page 1G-

17)”.

• After remounting the engine, route the wiring harness,

cables and hoses properly. Refer to “Wiring Harness

Routing Diagram in Section 9A (Page 9A-8)” and

“Throttle Cable Routing Diagram (Page 1D-1)”.

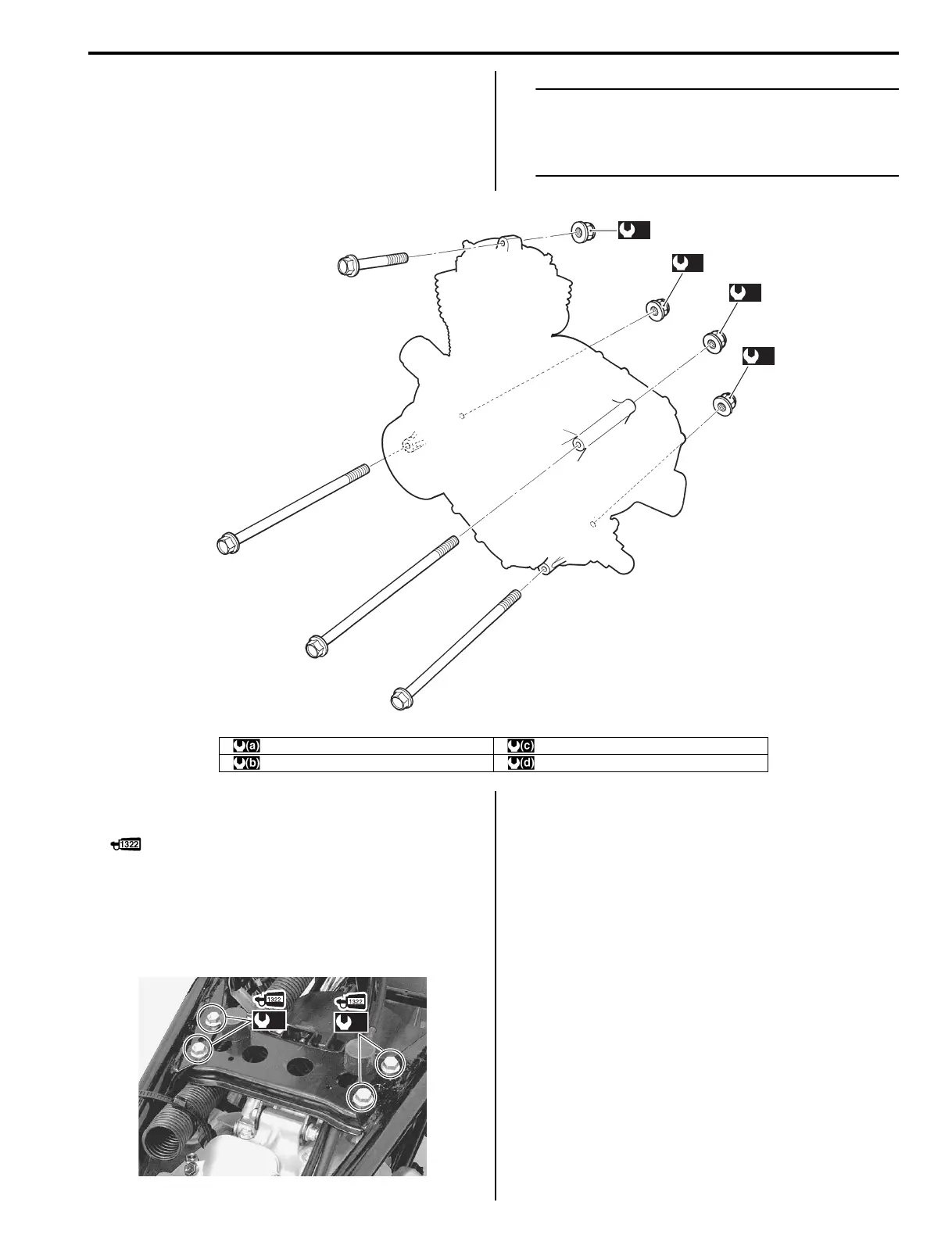

(b)

(a)

(c)

(d)

I827H1140252-01

:40 N⋅m (4.0 kgf-m, 29.0 lb-ft) : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

:55 N⋅m (5.5 kgf-m, 40.0 lb-ft) : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

(a)

(a)

I827H1140253-02

Loading...

Loading...