Fuel System: 1G-22

Cleaning

WARNING

!

Some carburetor cleaning chemicals,

especially dip-type soaking solutions, are

very corrosive and must be handled carefully.

Always follow the chemical manufacturer’s

instructions on proper use, handling and

storage.

1) Clean all jets with a spray-type carburetor cleaner

and dry them using compressed air.

2) Clean all circuits of the carburetor thoroughly – not

just the perceived problem area.

3) Clean the circuits in the carburetor body with a

spray-type cleaner and allow each circuit to soak, if

necessary, to loosen dirt and varnish.

4) Blow the body dry using compressed air.

CAUTION

!

Do not use a wire to clean the jets or

passageways. A wire can damage the jets

and passageways. If the components cannot

be cleaned with a spray cleaner it may be

necessary to use a dip-type cleaning solution

and allow them to soak.

Engine Idle Speed Inspection

B827H11706033

Refer to “Engine Idle Speed Adjustment in Section 0B

(Page 0B-13)”.

Fuel Line Inspection

B827H11706034

Refer to “Fuel Line Inspection in Section 0B (Page 0B-

7)”.

Air Cleaner Element Removal and Installation

B827H11706035

Refer to “Air Cleaner Element Removal and Installation

in Section 1D (Page 1D-5)”.

Air Cleaner Element Inspection and Cleaning

B827H11706036

Refer to “Air Cleaner Element Inspection and Cleaning in

Section 0B (Page 0B-3)”.

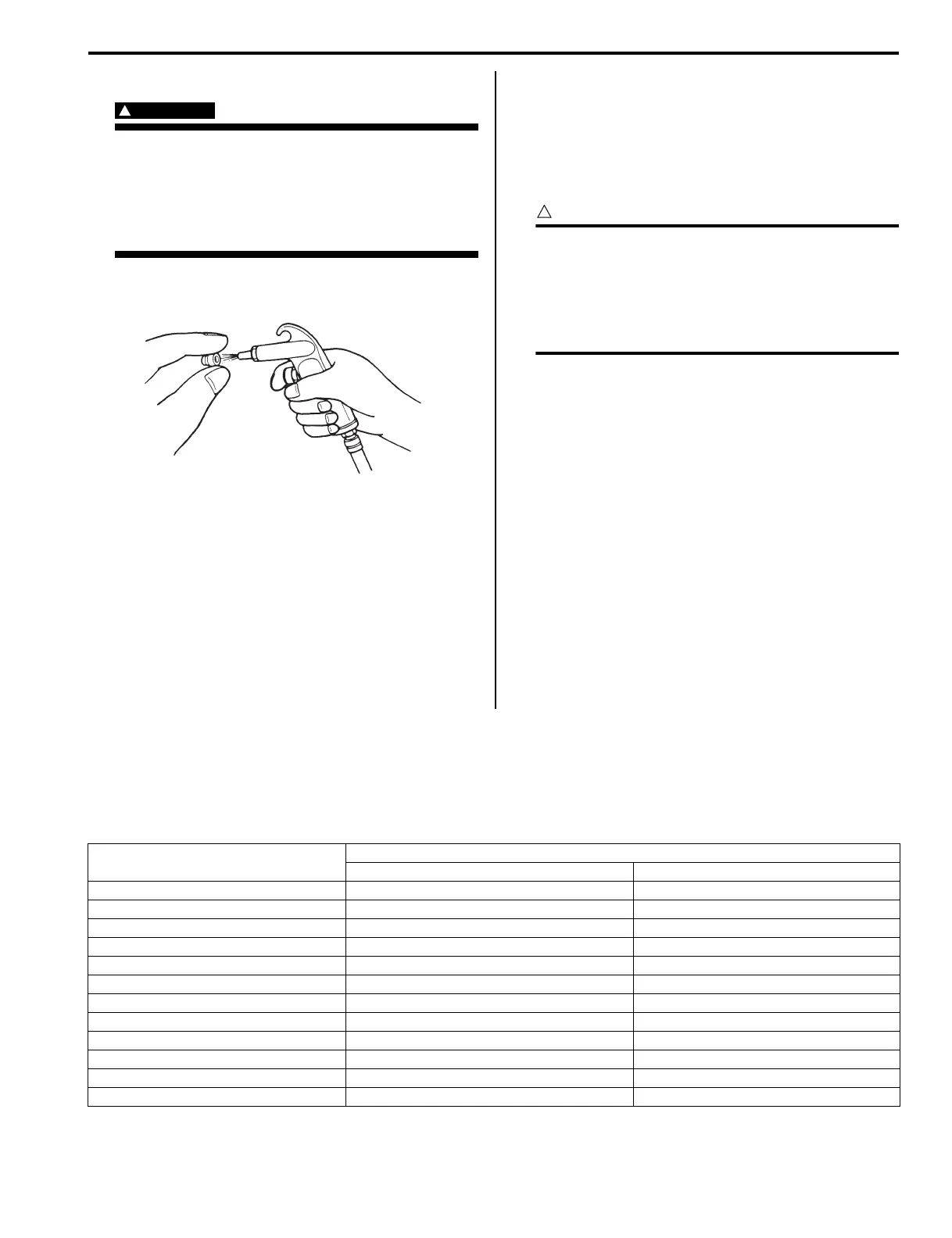

Specifications

Service Data (LT-A400/F, LT-F400/F)

B827H11707001

Injector + Fuel Pump + Fuel Pressure Regulator

I649G1170063-02

Item

Specification

P-17, 24, 28 P-33

Carburetor type KEIHIN CVK 32 ←

Bore size 32 mm (1.26 in) ←

I.D. No. 27H1 27H0

Idle r/min 1 500 ± 100 r/min ←

Float height 17.0 ± 1.0 mm (0.67 ± 0.04 in) ←

Main jet (M.J.) # 125 ←

Jet needle (J.N.) NLVM ←

Needle jet (N.J.) # 6 ←

Slow jet (S.J.) # 38 ←

Pilot jet (P.J.) 2 – 1/8 turns back PRE-SET

Throttle cable play 3.0 – 5.0 mm (0.12 – 0.20 in) ←

Starter cable play 0.5 – 1.0 mm (0.02 – 0.04 in) ←

Loading...

Loading...