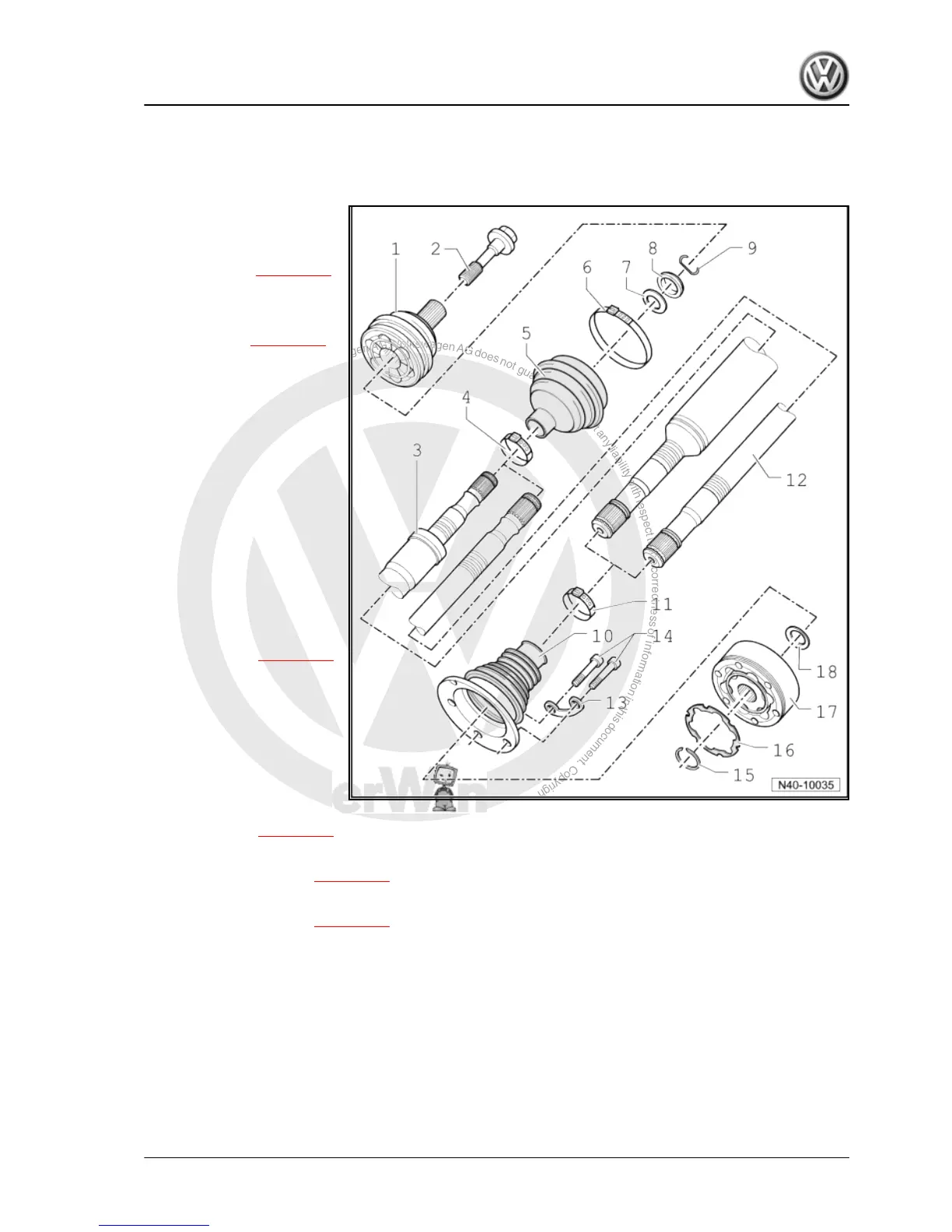

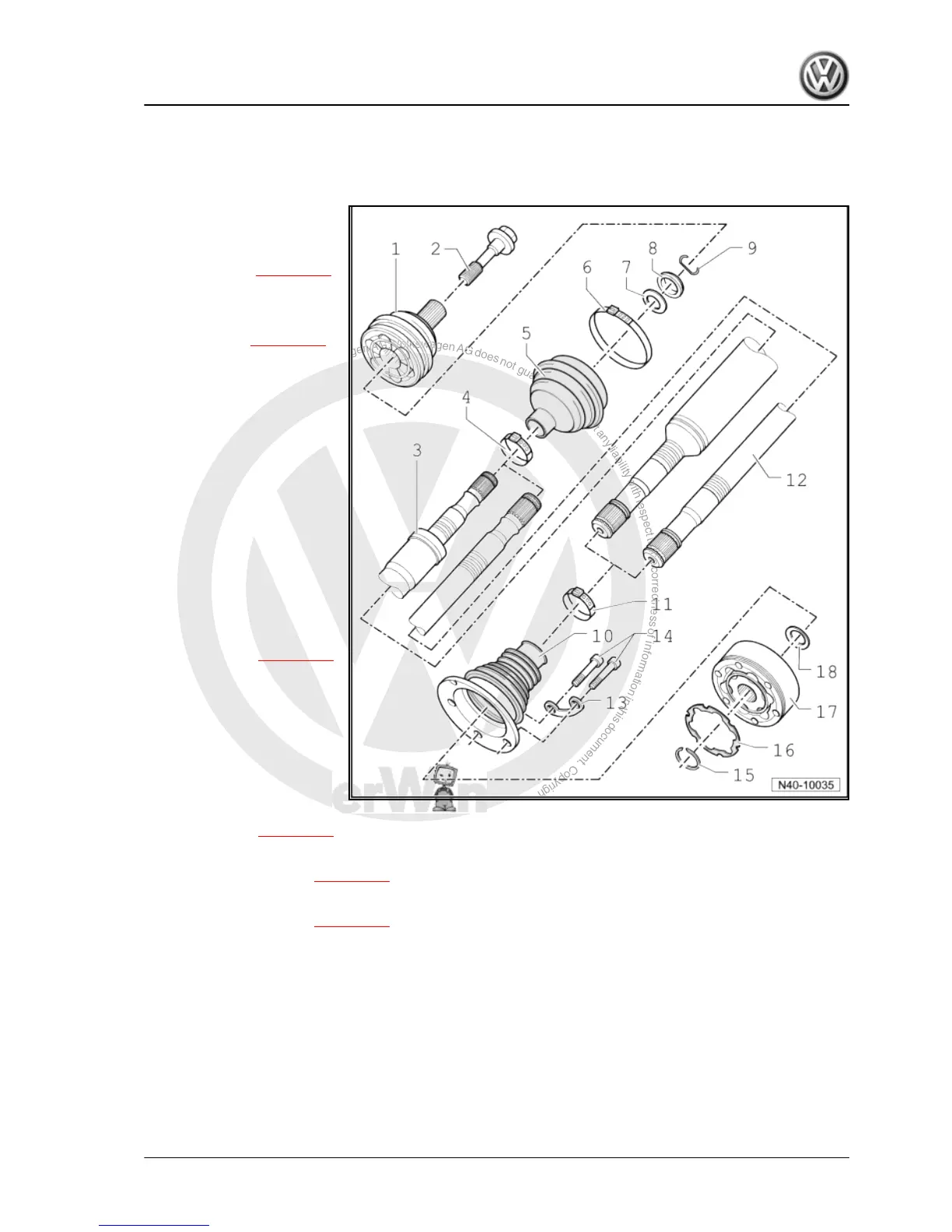

8 Assembly overview - drive shaft with VL90 or VL100 constant velocity

joint

1 - Outer constant velocity joint

❑ Renew only as com‐

plete unit

❑ Removing ⇒ page 101

❑ Installing: drive onto

shaft to stop using a

plastic mallet

❑ Checking ⇒ page 103

2 - Bolt

❑ M16 x 1.5 x 80

❑ Hexagon bolt, 200 Nm

and turn +180° further

❑ 12-point bolt, 70 Nm +

90° further

❑ Always renew after re‐

moving

When bolt is loosened or tight‐

ened, vehicle must not be

standing on its wheels

3 - Right drive shaft

4 - Hose clip

❑ Always renew after re‐

moving

❑ Tightening ⇒ page 103

5 - Boot

❑ Check for splits and

chafing

❑ Material: Hytrel (poly‐

ester elastomer)

6 - Hose clip

❑ Always renew after re‐

moving

❑ Tightening ⇒ page 103

7 - Dished spring

❑ Installation position ⇒ page 101

8 - Thrust washer

❑ Installation position ⇒ page 101

9 - Retaining ring

❑ Always renew after removing

❑ Insert in groove in shaft

10 - Boot for constant velocity joint

❑ Material: Hytrel (polyester elastomer)

❑ Without breather hole

❑ Check for splits and chafing

❑ Drive off constant velocity joint with a drift

❑ Coat sealing surface with D 454 300 A2 before installing constant velocity joint

Golf 2004 ➤ , Golf Plus 2005 ➤

Running gear, axles, steering - Edition 08.2009

8. Assembly overview - drive shaft with VL90 or VL100 constant velocity joint 97

Loading...

Loading...