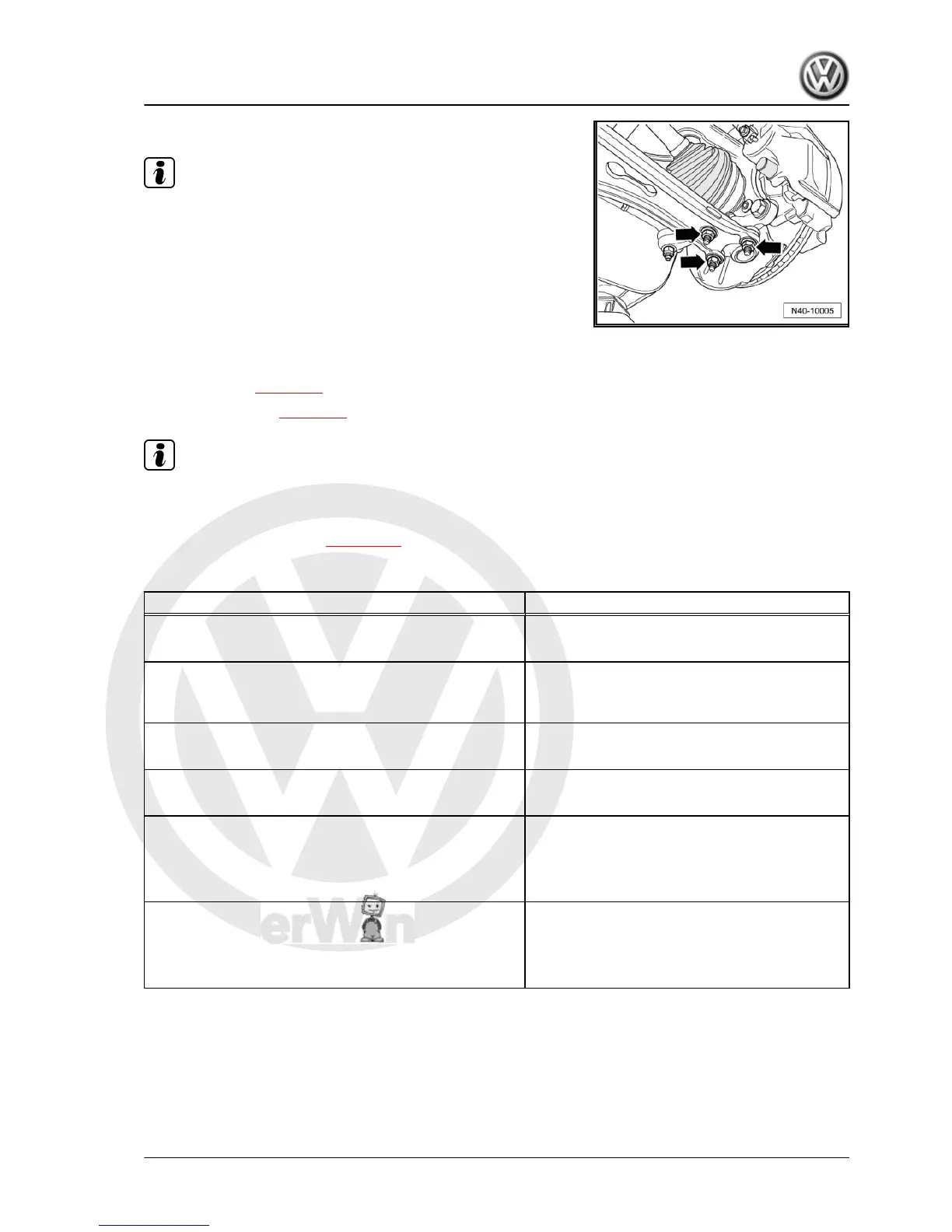

– Bolt swivel joint to suspension link -arrows-.

Note

Ensure boot is not damaged or twisted.

– Place inner joint of drive shaft in position and tighten bolts di‐

agonally to 10 Nm.

– Tighten multi-point socket-head bolts diagonally to the speci‐

fied torque.

– Attach lower noise insulation ⇒ Rep. Gr. 50 ; Assembly over‐

view - noise insulation .

– Tighten drive shaft bolt at wheel hub:

♦ Hexagon bolt ⇒ page 77

♦ Twelve-point bolt ⇒ page 78

Note

During this step, vehicle must not be standing on its wheels or

wheel bearing will be damaged.

– Install wheel and tighten ⇒ page 288 .

Specified torques

Component Specified torque

Swivel joint to cast steel suspension link

♦ Use new nuts

60 Nm

Swivel joint to sheet steel or forged aluminium suspension

link

♦ Use new nuts

100 Nm

Drive shaft to wheel hub “hexagon bolt”

♦ Use new bolt

200 Nm +180°

Drive shaft to wheel hub “12-point bolt”

♦ Use new bolt

70 Nm + 90°

Drive shaft to flange shaft on gearbox “M8 multi-point sock‐

et”

♦ Use new bolts

♦ Use new backing plates

40 Nm

♦ Initially tighten diagonally to 10 Nm.

Drive shaft to flange shaft on gearbox “M10 multi-point

socket”

♦ Use new bolts

♦ Use new backing plates

70 Nm

♦ Initially tighten diagonally to 10 Nm.

6.4 Removing and installing left drive shaft

with (push-on) constant velocity slip joint

Special tools and workshop equipment required

Golf 2004 ➤ , Golf Plus 2005 ➤

Running gear, axles, steering - Edition 08.2009

6. Removing and installing drive shafts 81

Loading...

Loading...