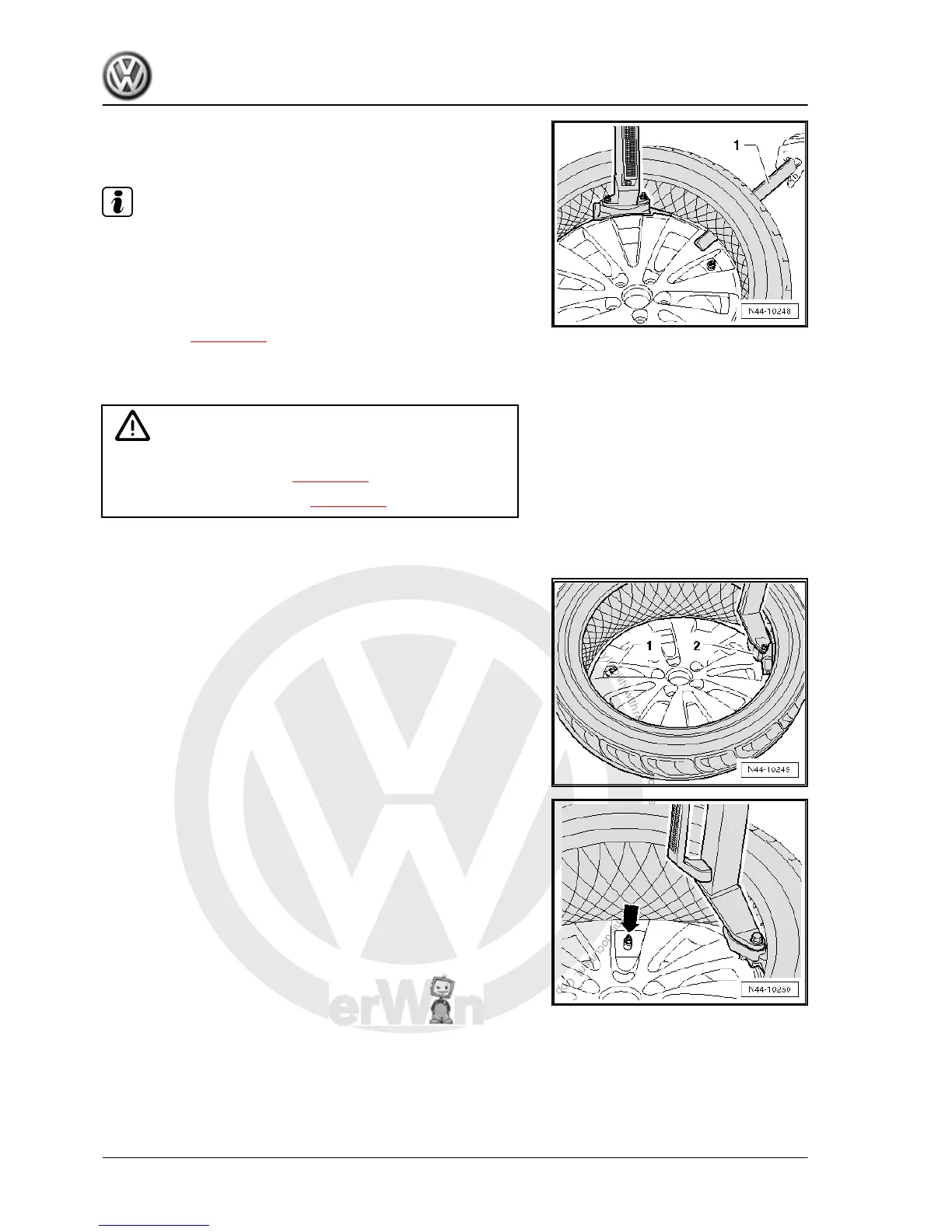

– Hold bead over wheel rim flange from outside using plastic

assembly lever -1- and run tyre fitting machine clockwise until

tyre is pulled completely off wheel rim.

Note

♦

Check that the tyre pressure sensor is not loose or damaged.

If the screwed connection is loose, replace the union nut, the

valve insert, the seal, the sealing washer and the valve cap

with new parts from the repair set ⇒ Electronic parts catalogue

“ETKA” .

♦

If the tyre pressure sensor is damaged, then replace the com‐

plete item ⇒ page 304 .

5.5 Fitting tyre to wheel rim

Caution

♦ Follow the instructions for warming cold tyres to minimum

installation temperature ⇒ page 294

♦ Follow the notes on safety ⇒ page 294

– Coat wheel rim flanges, tyre beads and inside of upper tyre

bead generously with tyre assembly paste.

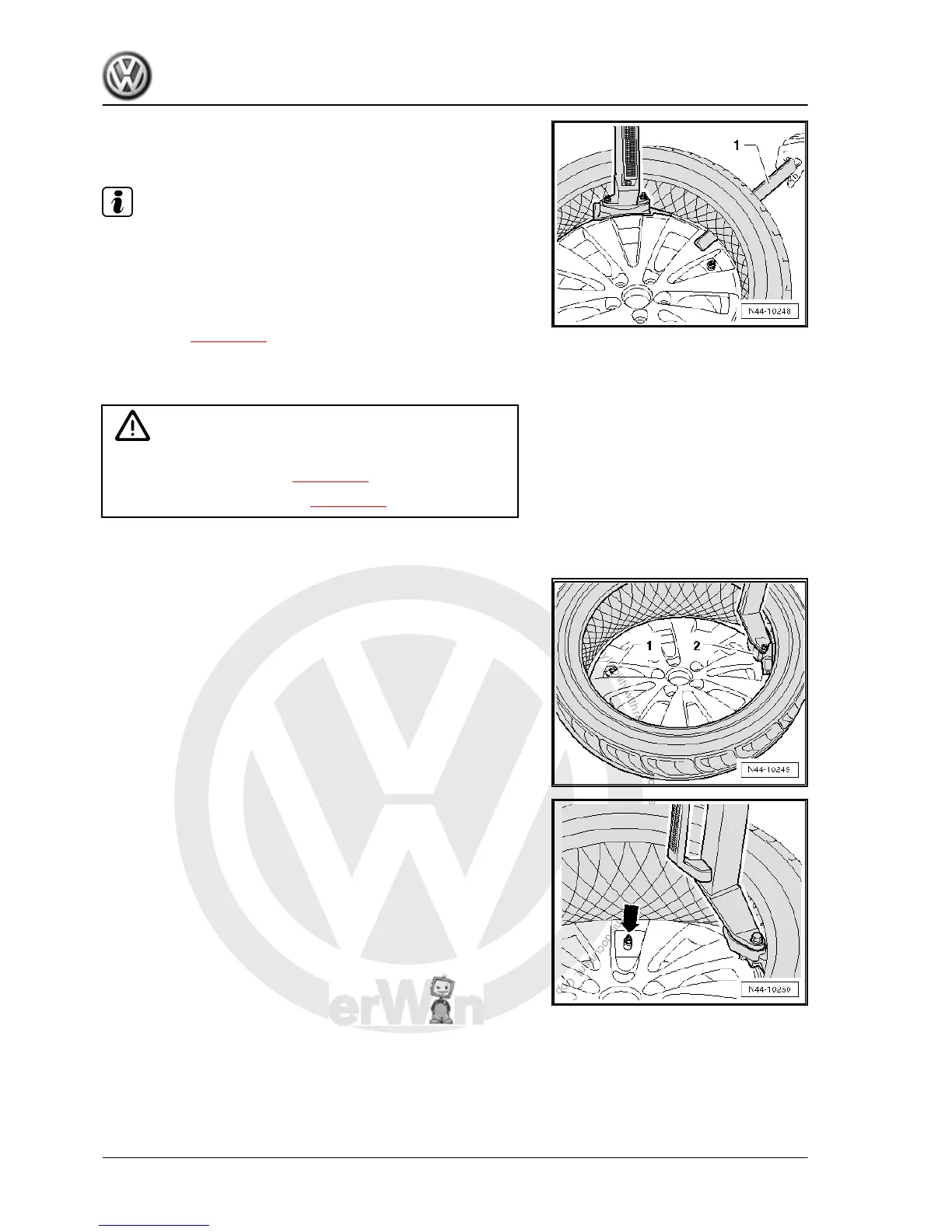

– Turn wheel rim on tyre fitting unit so that tyre valve/ tyre pres‐

sure sensor -1- is directly opposite assembly head -2-.

– Run tyre fitting machine clockwise.

– Stop the fitting of lower bead before reaching tyre valve/ tyre

pressure sensor -arrow- to prevent damage to tyre pressure

sensor .

The tyre bead will now slide over the wheel rim flange. The wheel

rim may only be turned until the assembly head is just before the

tyre valve/ tyre pressure sensor -arrow-.

Golf 2004 ➤ , Golf Plus 2005 ➤

Running gear, axles, steering - Edition 08.2009

298 Rep. Gr.44 - Wheels, tyres, vehicle geometry

Loading...

Loading...