6-4 OM ET18/20/24 us 1.3 * et18_20_24t600.fm

6

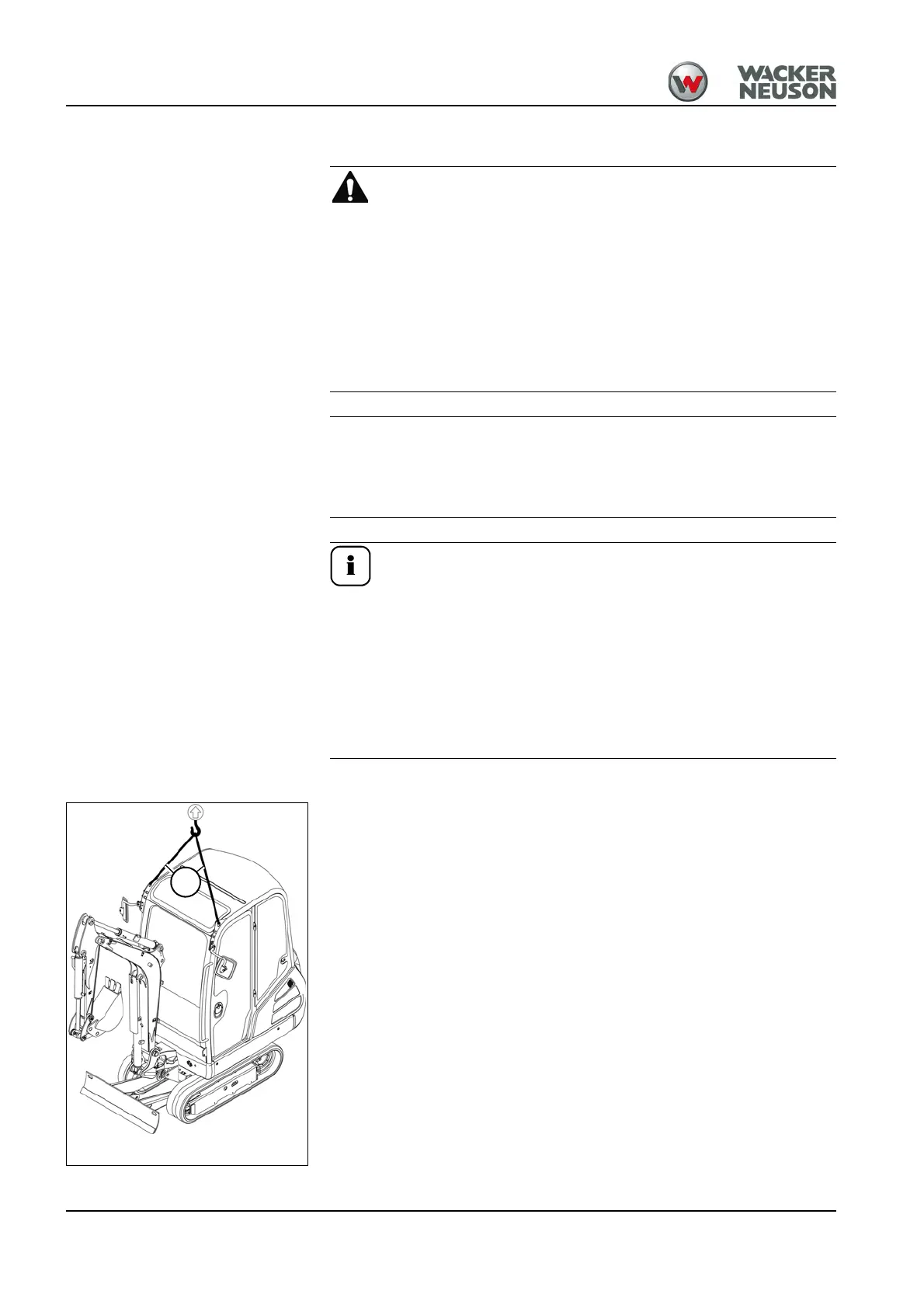

Lifting the machine

Accident hazard due to incorrect loading!

Incorrect loading can result in accidents and severe injury or

death.

► There must be no one in the machine or in the danger zone

when the machine is raised.

► Read the transport weight off the type label. Add the weight of

subsequently installed equipment to the weight of the

machine.

Engine damage due to incorrect engine oil level.

► The oil level must be visible at the MAX mark.

Use OSHA-rated and approved lifting devices capable lifting the

excavator, attachments, options and accumulated debris. Refer

to the general weight guidelines in the specification section of

this manual.

Do not attempt to lift the excavator with any type of crane

including wheel loaders unless the crane operator is qualified to

lift loads in craning operations. The crane operator shall be

knowledgable of OSHA 1910 craning regulations.

1. Fit an empty standard bucket and lock it safely.

2. Remove all dirt from the machine.

3. Place the machine on firm, level and horizontal ground.

4. Curl the standard bucket and lower it to transport position.

5. Fully raise the boom.

6. Pull the stick toward the machine.

7. Raise the stabilizer blade.

8. Position the boom straight ahead at the center of the machine.

9. Stop the engine.

10.Operate the control lever repeatedly to release the pressure in the

hydraulic system.

11.Raise the control lever base.

12.Remove the starting key and carry it with you.

13.Remove all loose objects from inside the machine.

14.Leave the cab, close and lock all doors, windows and covers.

15.Install suitable slings at the points provided for lifting the machine.

16.Slowly raise the machine until there is no more contact with the

ground.

Fig. 217: Craning operation

L1

Loading...

Loading...