5-106

E

POWR

1

2

3

4

5

6

7

8

9

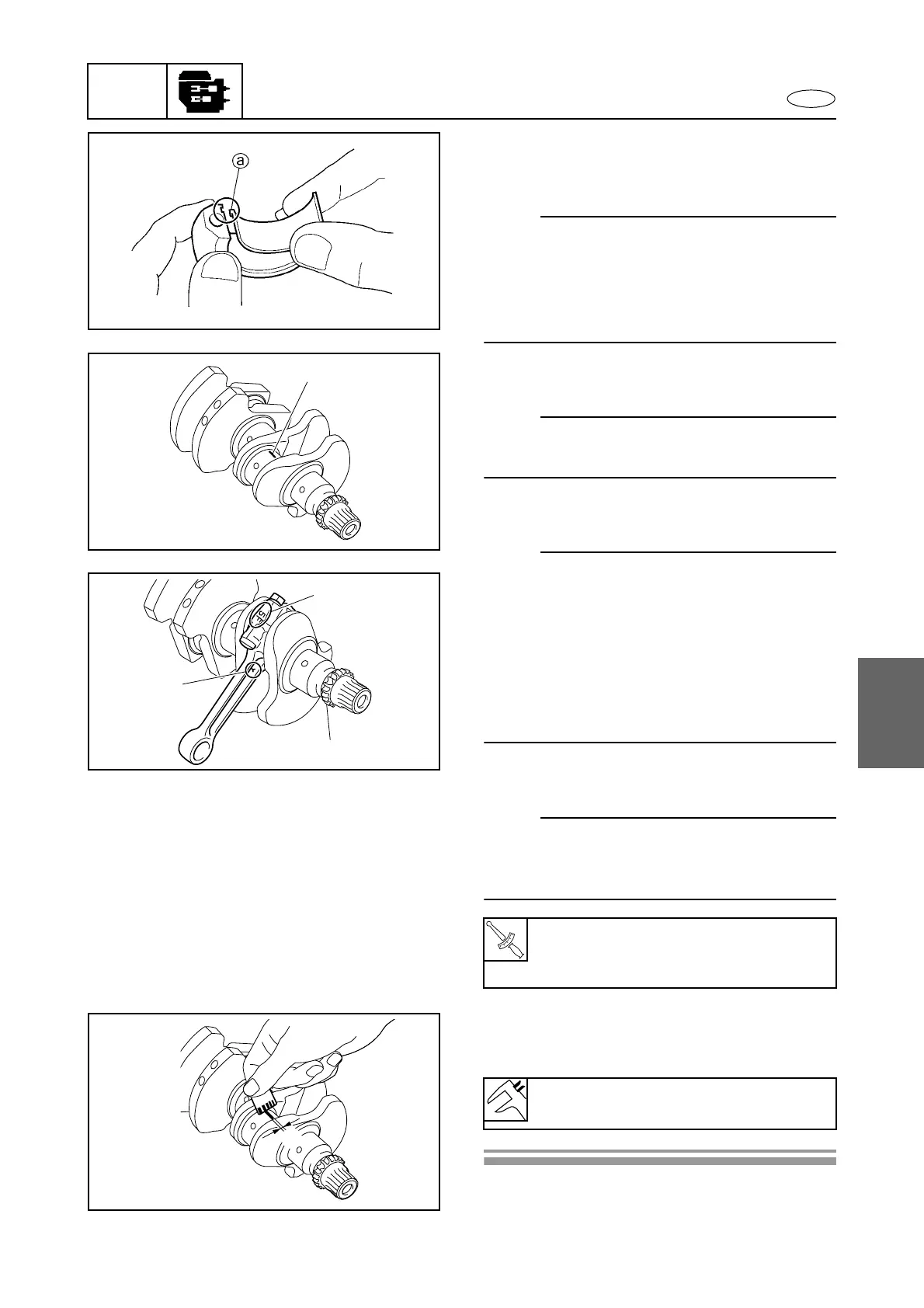

2. Install the upper bearing into the connect-

ing rod and lower bearing into the connect-

ing rod cap.

NOTE:

• Install the connecting rod bearings in their

original positions.

• Insert the projection a of each bearing into

the slots in the connecting rod cap and con-

necting rod.

3. Put a piece of Plastigauge 1 onto the

crankshaft pin, parallel to the crankshaft.

NOTE:

Do not put the Plastigauge over the oil hole in

the crankshaft pin.

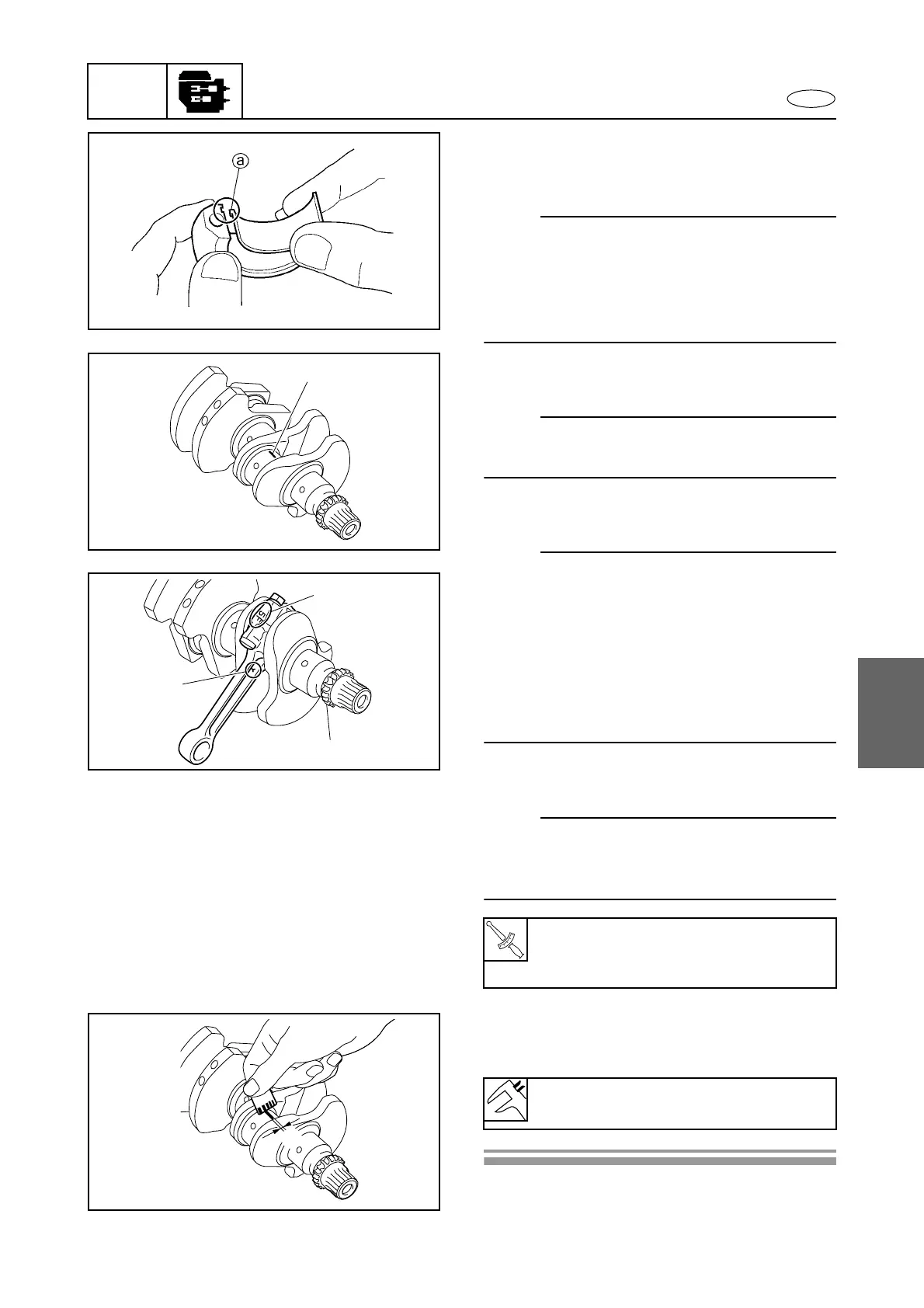

4. Install the connecting rod onto the crank-

shaft pin.

NOTE:

• Apply engine oil to the connecting rod bolts

threads and nut seats.

• Make sure that the “Y” mark b on the con-

necting rod faces towards the timing chain

drive gear c of the crankshaft.

• Make sure that the characters d on both the

connecting rod and connecting rod cap are

aligned.

5. Tighten the connecting rod nuts to the

specified torques in 2 stages.

NOTE:

Do not turn the connecting rod until the crank-

shaft pin oil clearance measurement has been

completed.

6. Remove the connecting rod cap and mea-

sure the width e of the compressed Plas-

tigauge on each crankshaft pin.

T

R

.

.

Connecting rod nut:

1st: 51 N·m (5.1 kgf·m, 37.6 ft·lb)

2nd: 90°

Crankshaft pin oil clearance:

0.020–0.056 mm (0.0008–0.0022 in)

1

b

d

c

e

Crankcase, connecting rod, and piston

Loading...

Loading...