4 Cabling the AC 800F

4-64

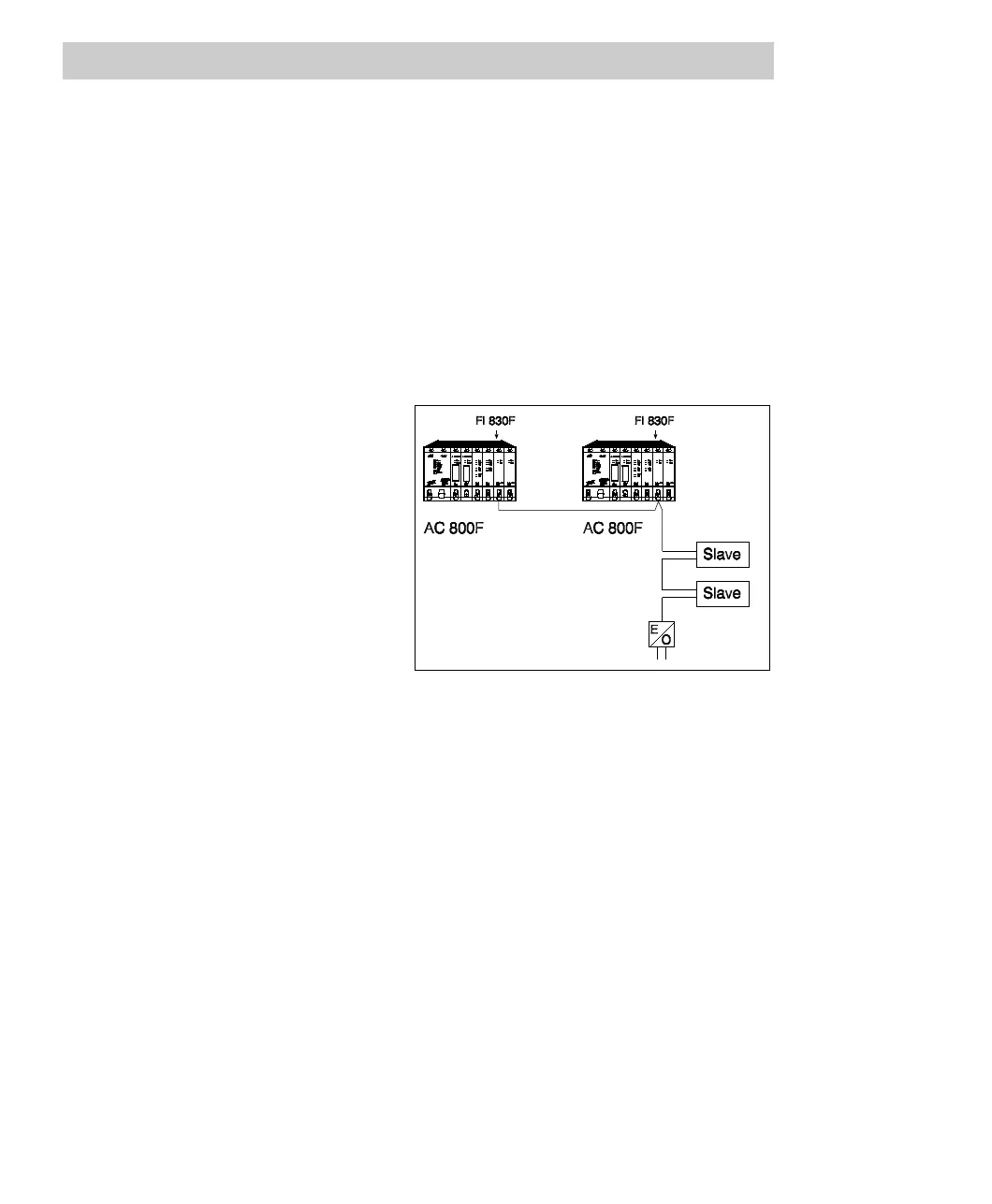

4.3.1.3 Connecting a Profibus master redundancy

The Profibus module FI 830F is suitable for Profibus master redundancy. The

redundant AC 800F accommodating the redundant Profibus module can be

connected to the Profibus like any other Profibus node. It communicates with the

current Profibus master via the Profibus. Thus, the redundant unit is permanently

checked for proper functioning, over all communication levels. Observe the

instructions given above for connecting a Profibus via RS485.

The process data on the primary (i.e. active) AC 800F are permanently matched with

those on the secondary (i.e. redundant) AC 800F via the redundancy link. For this

purpose, a point-to-point connection is established between the two redundant

AC 800F. This ensures both rapid and deterministic data transfer.

Set the coding switch on the

Ethernet module to the

appropriate position to define

whether or not the Ethernet

module should have the special

features required for redundancy

communication. Refer to Section

5.4 for details.

If a change-over to redundancy

mode occurs, the Profibus

module of the secondary unit

nearly bumplessly takes over all

nodes on the Profibus and

continues process control.

Fig. 4-40 Profibus master redundancy

4.3.1.4 Connecting a Profibus line redundancy

No line redundancy has been implemented in the Profibus module FI 830F. If,

however, an analysis of the system availability shows the necessity of redundant

Profibus cabling, it is recommended to use a redundancy link module RLM 01. This

module connects the RS485 interface of the Profibus module to two Profibus lines.

The data are then transmitted on both lines in parallel. In the receive branch of the

RLM 01 the data are analyzed by a special ASIC, and only those from the properly

working line are further transmitted. This intelligent handling of the two redundant

Profibus lines ensures that no data are lost or corrupted when a switch-over occurs.

Loading...

Loading...