Maintenance 2. Periodic Inspection

S5 Rev.5

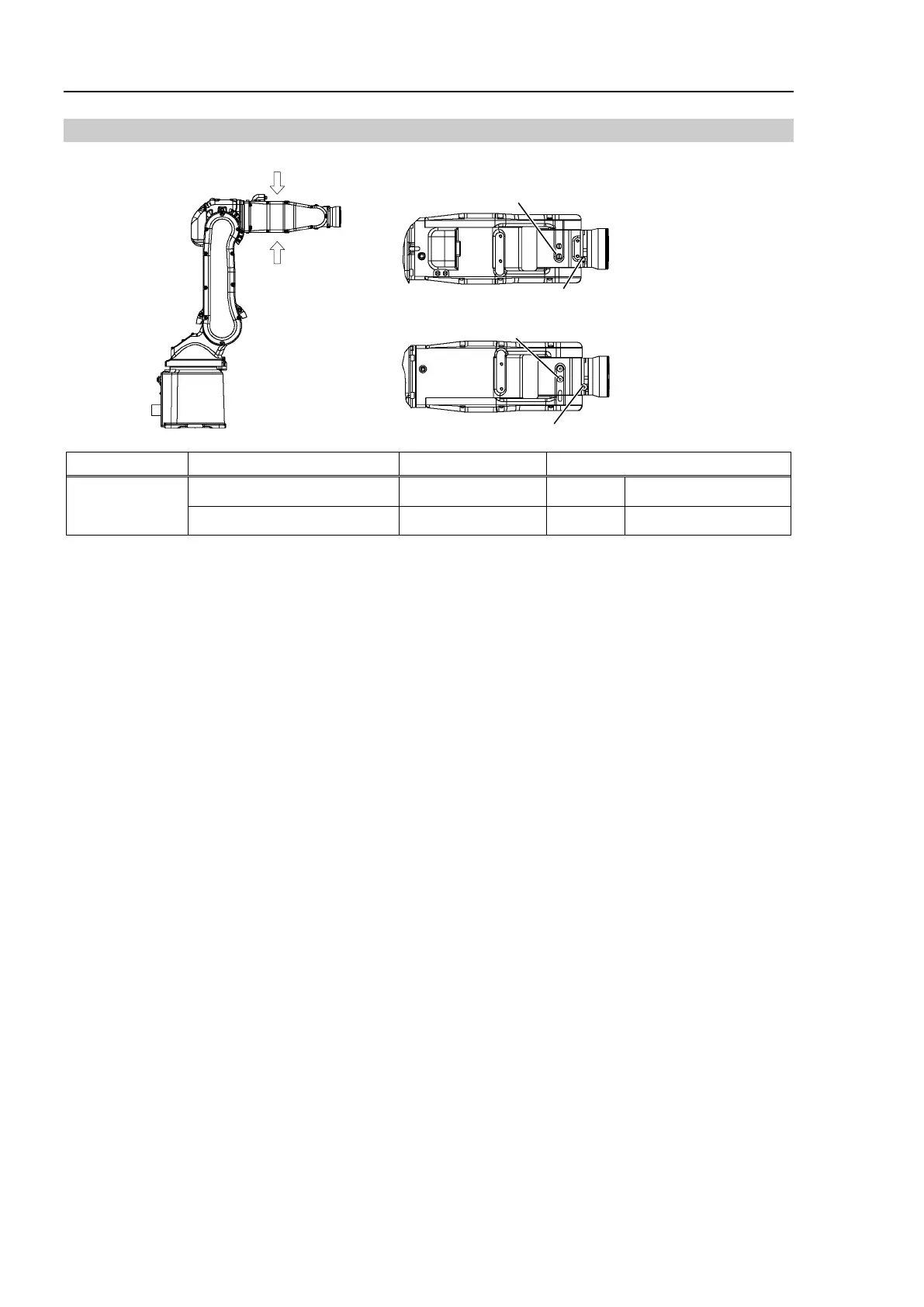

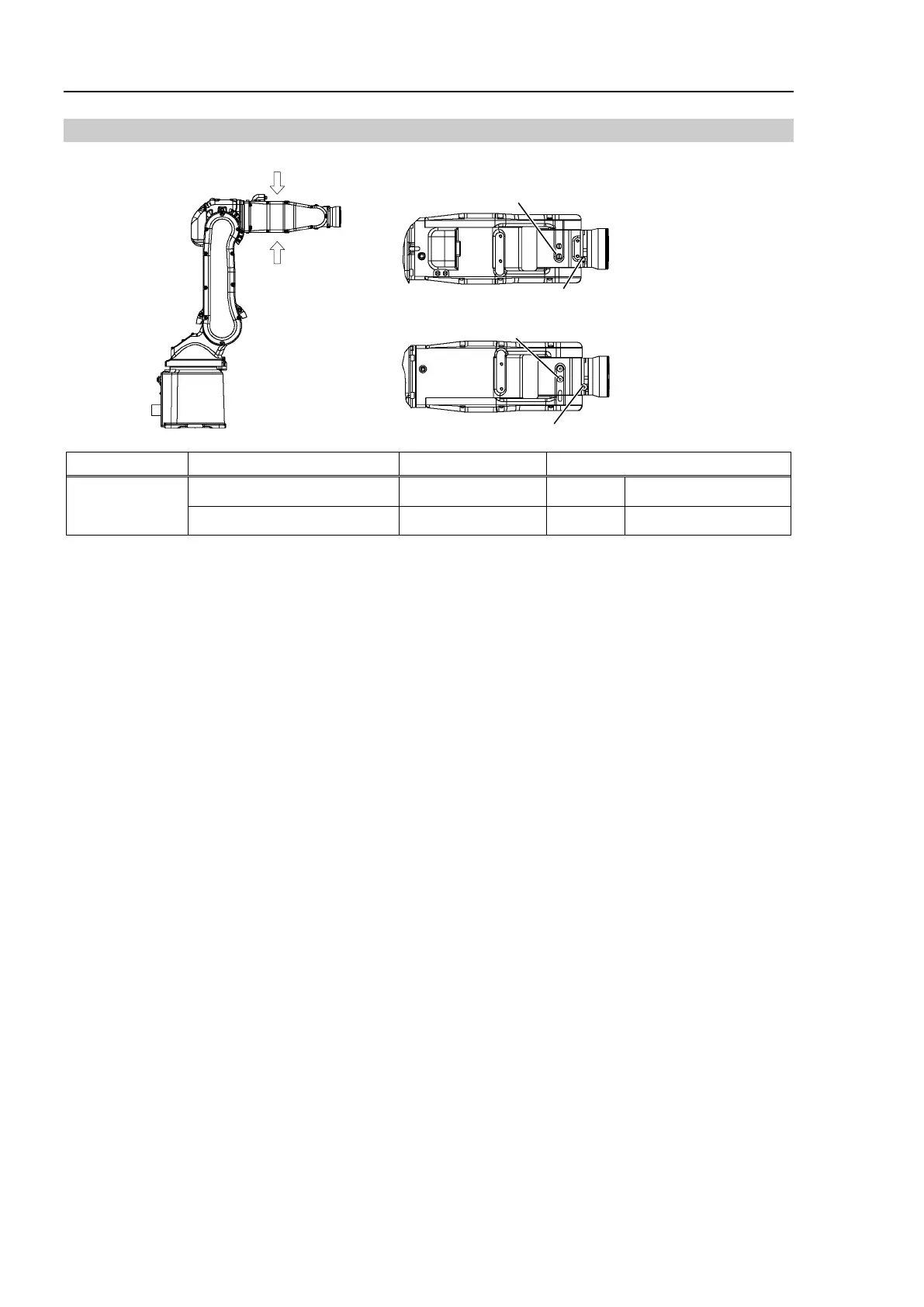

2.3.7 Joint #6 Reduction Gear Unit

Air Vent: Gear part (Plug M5)

Grease Inlet: Reduction Gear Unit (Plug M5)

Grease Inlet: Gear part (Plug M5)

Air Vent: Reduction Gear Unit (Plug M5)

Maintenance

Parts

Grease for reduction gear

Liquid gasket Proper quantity 1206C R13B031201

Remove the plug from the grease inlet.

Plug: LP-M5

Attach a grease nipple to the grease inlet.

(The grease nipple is supplied with the Manipulator.)

Grease nipple: M5

Remove the plug from the air

vent.

Plug: LP-M5

Be sure to remove the plug from the air vent. When grease is

being added

while

the plug is in the air vent, the internal

pressure increases

. Increasing internal

pressure may cause malfunction of the robot system.

grease into the reduction gear unit from the grease inlet using a grease gun.

Grease : Grease for reduction gear (SK-1A)

Quantity : 5 g

Operate the Manipulator at low power mode speed for one hour to run

-in the grease.

Wipe off excess grease exhausted f

rom the air vent with wiping cloth.

Attach the plug to the air vent.

Plug: LP-M5 (Apply liquid gasket.)

Remove the grease nipple from the grease inlet.

Grease nipple: M5

Attach the bolt to the grease inlet.

Plug: LP-M5 (Apply liquid gasket.)

Loading...

Loading...