Setup & Operation 3. Environment and Installation

S5 Rev.5 33

Removal

Remove the bolts combining

the shipping jigs at the point A.

-M5×14 hexagon socket head cap bolts with plain washers and disc spring washers

securing the shipping jigs at the point B. Then, remove the upper

s.

-M6×10 hexagon socket head cap bolts with plain washers and disc spring washers

Before turning on the power, be sure that the shipping bolts and jigs have been removed.

The shipping bolts and jigs must then be stored for future use, in the event that the

Manipulator must be moved again.

Installation

sition the Manipulator as show in the figure above.

2)

Attach the upper part of the shipping jigs to the Manipulator at the point

B

. Secure

it with the bolts.

-M6×10 hexagon socket head cap bolts with plain washers and disc spring washers

3)

Secure the shipping jigs at the point

A with the bolts.

-M5×14 hexagon socket head cap bolts with plain washers and disc spring washers

3.2.4 Relocating

Follow the procedures described below when relocating the Manipulator.

for all devices and unplug the cables.

Remove the mechanical stops if using them to limit the motion range

.

n the motion range, refer to the Setup & Operation 5.2

Motion Range

Setting of Arm #

1 by Mechanical Stops.

.

Then, remove the Manipulator from the base table.

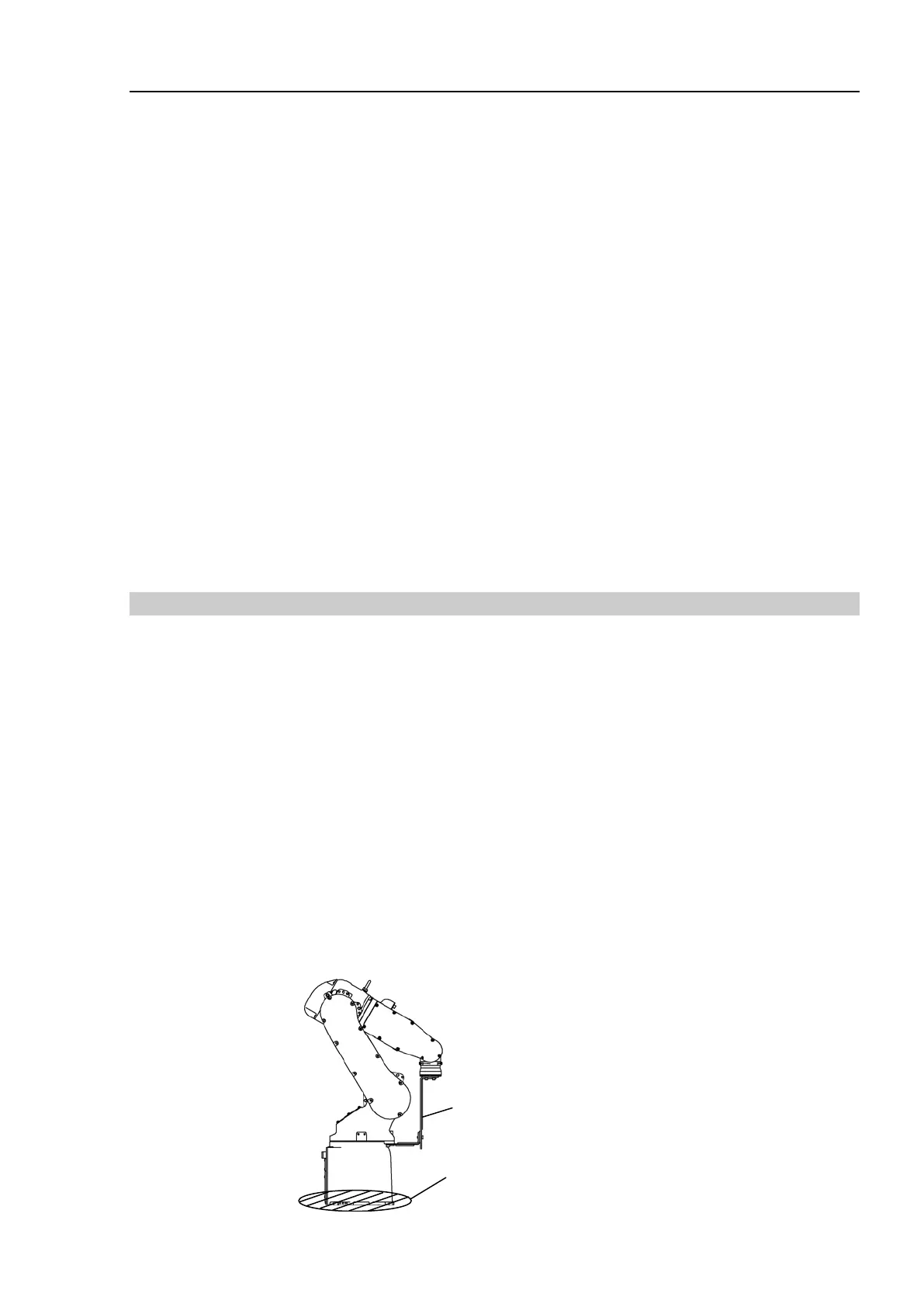

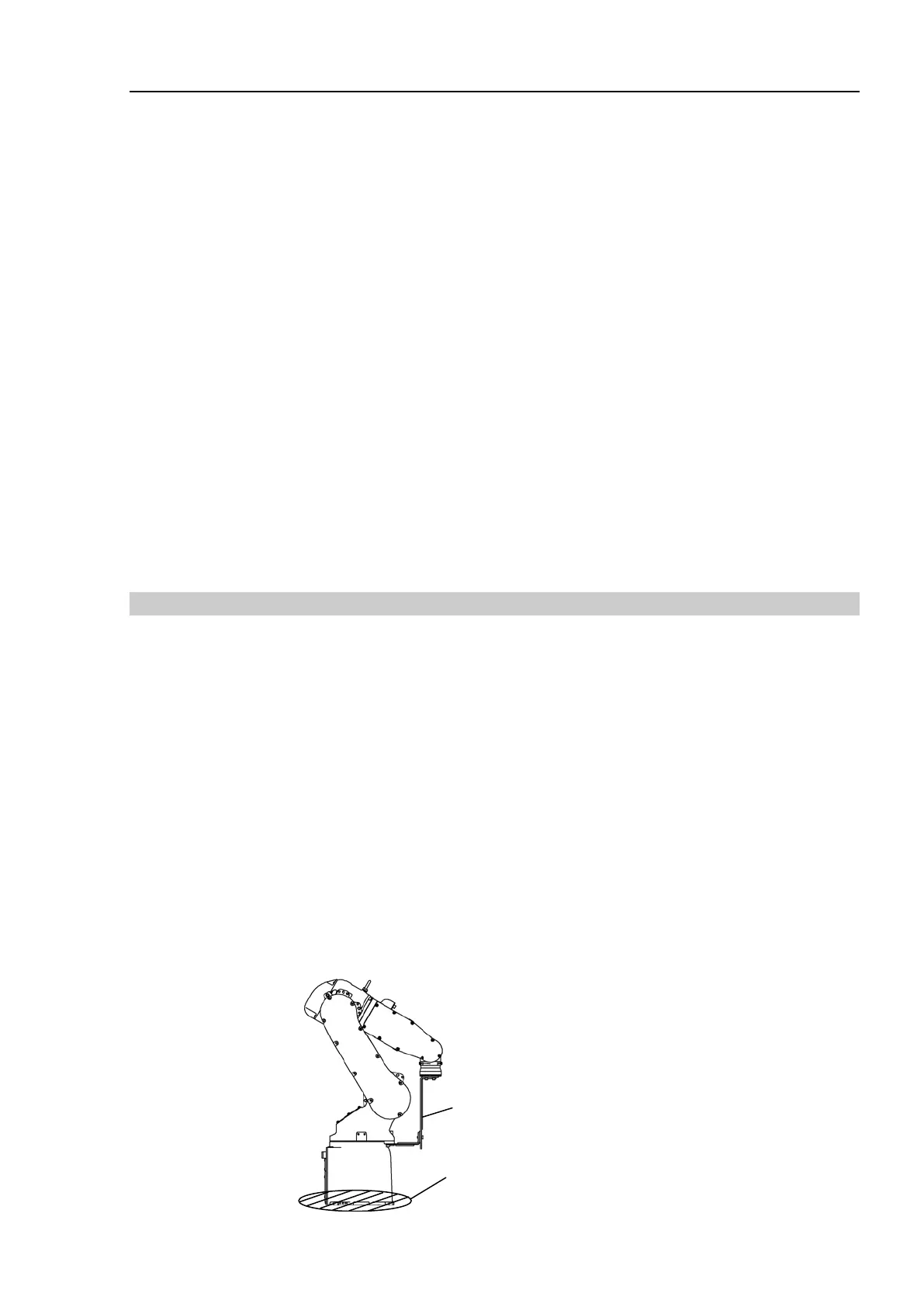

ition

the Manipulator as shown in the figure. Then, secure the Manipulator to

the delivery equipment or have three or more people to carry the Manipulator.

Do not hold the bottom of the base (the screened parts in the figure). Holding these

parts by hand is

extremely hazardous and may cause your hands and fingers to be

caught or cut by the

grounding electrode.

S5-A701**

Approx. 38 kg (Manipulator weight: 36 kg (80 lb.))

S5-A901**

Approx. 40 kg (Manipulator

weight: 38 kg (84 lb.))

DO NOT hold

the bottom of the

base by hand.

Loading...

Loading...