Maintenance 2. Periodic Inspection

S5 Rev.5 83

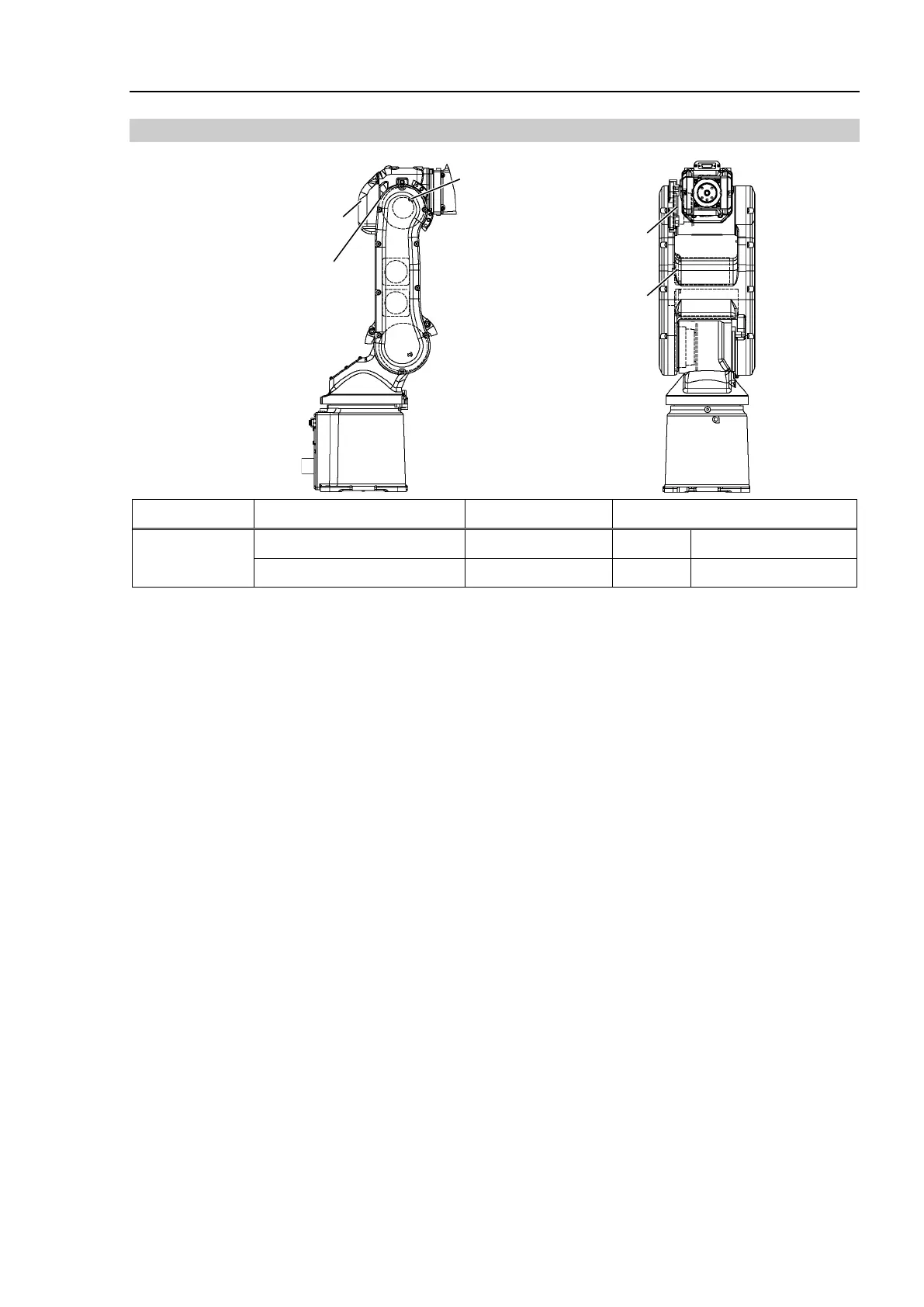

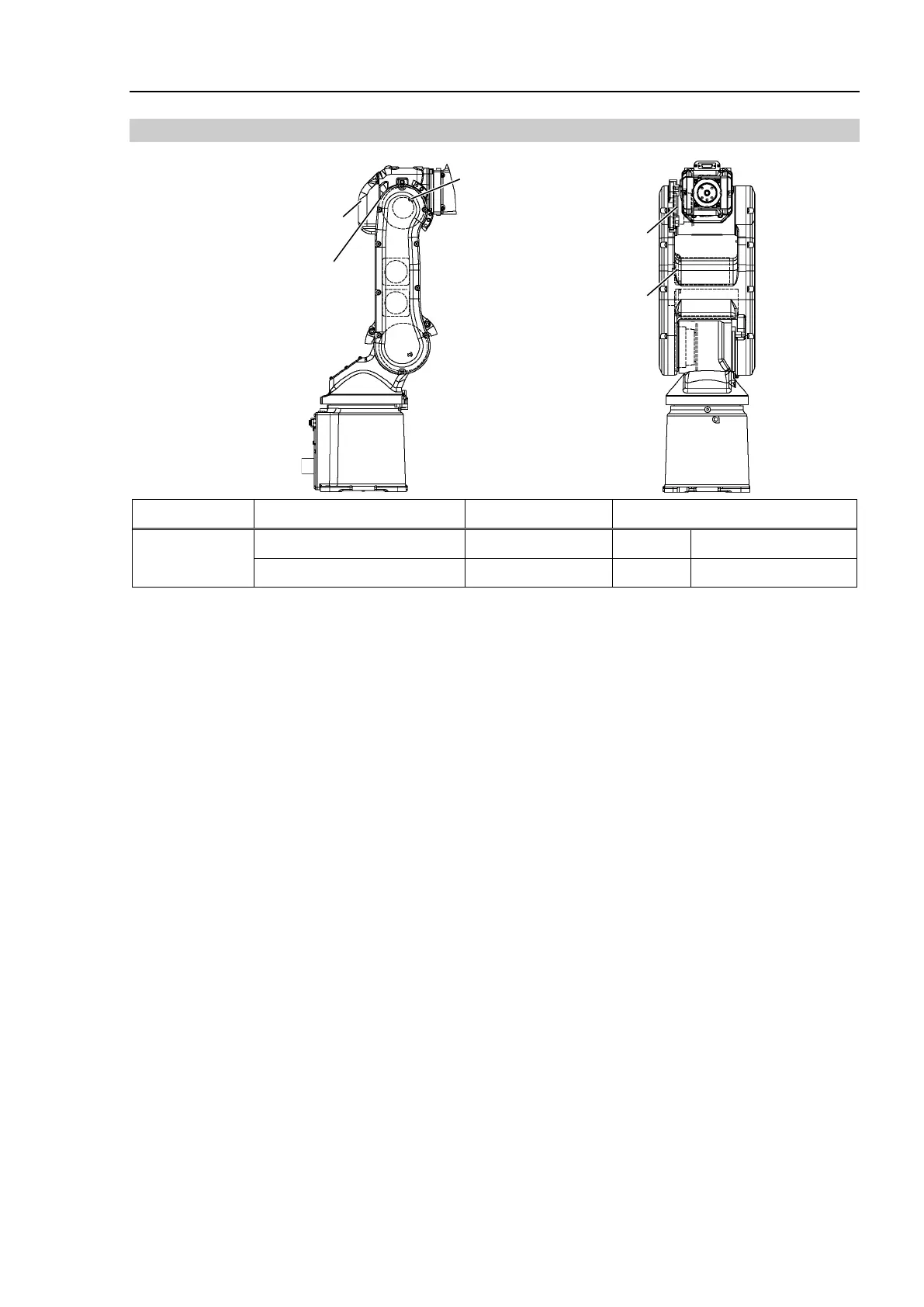

2.3.4 Joint #3 Reduction Gear Unit

Joint #3

Reduction Gear Unit

Grease Inlet

(Hexagon Socket

Head Cap Bolt : M6)

Name Quantity Note

Maintenance

Parts

Grease for reduction gear 20 g SK-1A R13ZA00330100

Remove the bolt from the grease inlet.

Hexagon socket head cap bolt: M6

Attach a grease nipple to the grease inlet.

(The grease nipple is supplie

d with the Manipulator.)

Grease nipple: A-MT6×1

Remove the plug from the air vent.

Plug: LP-M5

Be sure to remove the plug from the air vent. When grease is

being added

while the

plug is in the air vent, grease will go inside the motor and may cause malfunction of

the robot system.

grease into the reduction gear unit from the grease inlet using a grease gun.

Grease : Grease for reduction gear (SK-1A)

Quantity : 20 g

Operate the Manipulator at low power mode speed for one hour to

run-in the grease.

Wipe off excess grease exhausted from the air vent with wiping cloth.

Attach the plug to the air vent.

Plug: LP-M5 (Apply liquid gasket.)

Remove the grease nipple from the grease inlet.

Grease nipple: A-MT6×1

ch the bolt to the grease inlet.

Hexagon socket head cap bolt: M6 (Apply liquid gasket.)

Loading...

Loading...