SC-S30600 Series Revision B

ADJUSTMENT Overview 210

Confidential

4.1.3 Adjustment Items

The following table describes the general outline of the adjustments.

Table 4-2. Adjustment Items

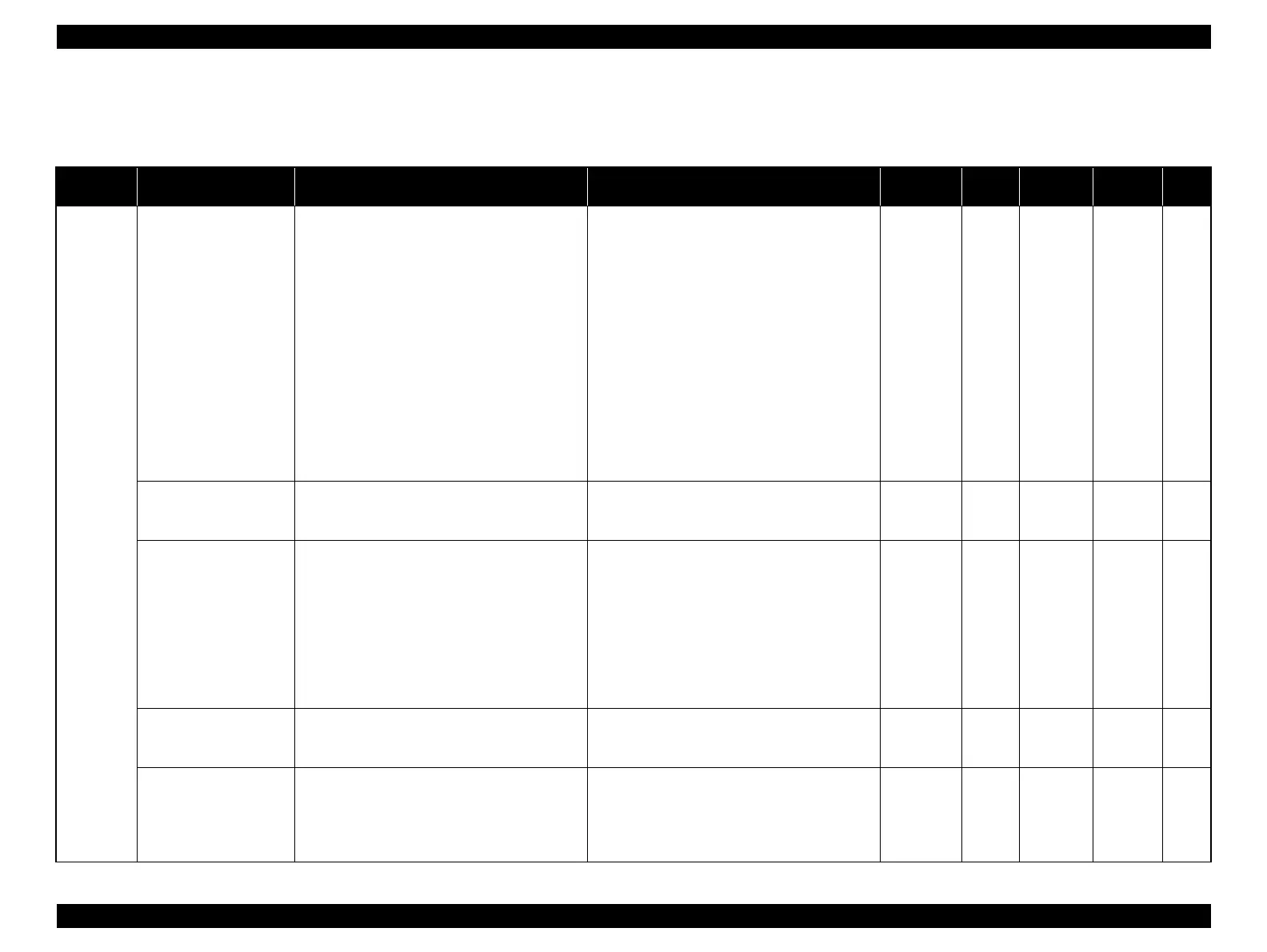

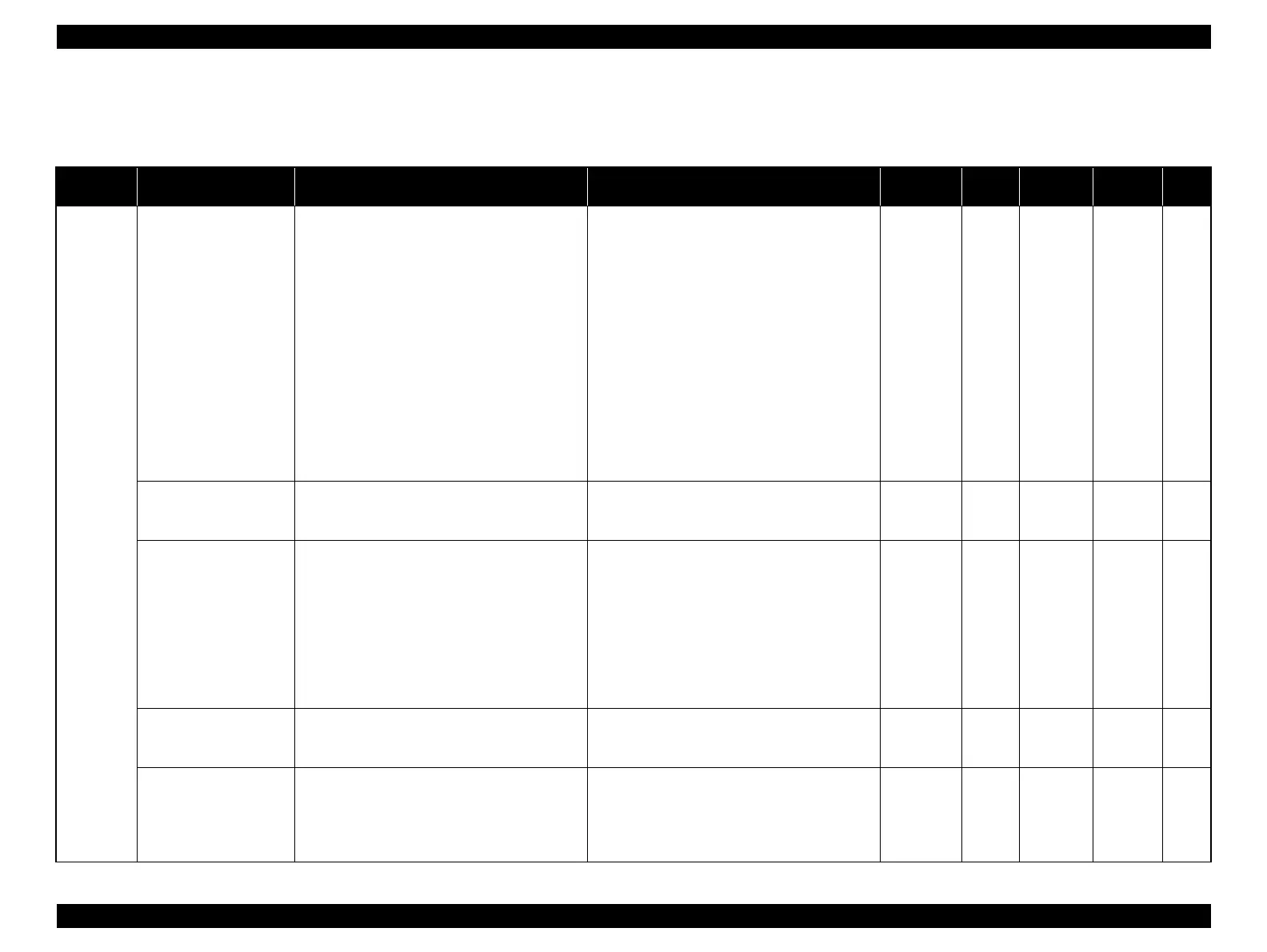

Class Adjustment Items Overview Symptoms that the Adjustment is Needed Printer Mode

Service

Program

Jig Media Page

CR related

CR Belt Tension Check

Apply a specified tension to the CR timing belt.

Measure the tension of the belt using the sonic

tensimeter to check if it is within standards. If

not, adjust the tension.

When the belt tension is out of standards, the

following symptoms may occur.

Belt tension is high:

The life of the belt will be shortened. High

load applied to the carriage causes frequent

wait control over the carriage movements to

prevent overheating. If the tension is too high,

the shaft of the motor leans and the brush in

the motor becomes worn, and will result in CR

overload error (113A).

Belt tension is low:

The belt teeth slip and the carriage swings.

The correction by the active damper does not

work and the bands (vertical bands) occur near

the side edges of paper.

Normal

mode

Tensimeter

U-507

p.233

APG function check

Rotate the APG motor to change the PG, and see

if the PG is correctly set to its home position

(TYP).

When the PG is not switched properly responding

to the print setting, low image quality or CL

operation abnormality may occur.

Normal

mode

p.236

Ink Mark Sensor check &

Auto Adjustment

Check if the Ink Mark Sensor has any trouble/

connection failure.

Execute IMS Position Auto Correction

(pattern detecting position correction).

Correct the detecting position of the print

pattern in the sub scan direction and the main

scan direction.

Run the nozzle check to check if the Ink Mark

Sensor detects the nozzle clogging properly.

If the IMS does not work properly, automatic

adjustments such as Auto Bi-D Adjustment

cannot be executed normally.

Normal

mode

3M IJ40-

10R

p.238

CR Scale Check

Check the CR Scale for any abnormality such as

damage or dirt and check if the scale can be

properly read by the encoder.

When the CR Scale is not read properly, the

carriage will not operate normally.

Normal

mode

p.239

CR Active Damper

Adjustment (Automatic)

Calibrate the active damper.

* Active damper is a function to reduce the

carriage vibration which causes vertical bands on

prints by outputting waveforms which have

phases opposite to the motor vibration.

Because the motor vibration/carriage vibration

cannot be reduced, vertical bands may appear on

prints.

Normal

mode

p.240

Loading...

Loading...