283

16 Maintenance

There will be times when the machine will require maintenance tasks to be carried out.

Information contained in this chapter will assist with these tasks.

Cleaning the Machine

Proper maintenance is important for the smooth operation of any equipment.

NOTE: When cleaning the machine, do not use organic or strong chemical solvents or

aerosol cleaners. Do not pour fluids directly onto any area. Avoid supplies that are not

specifically listed as approved in this documentation; they can cause poor

performance and create a dangerous situation. Use supplies and cleaning materials

only as directed in this documentation. Keep all cleaning materials out of the reach of

children.

NOTE: Do not remove the covers or guards that are fastened with screws. You cannot

maintain or service any of the parts that are behind these covers and guards. Do not

attempt any maintenance procedure that is not specifically described in the

documentation supplied with the machine.

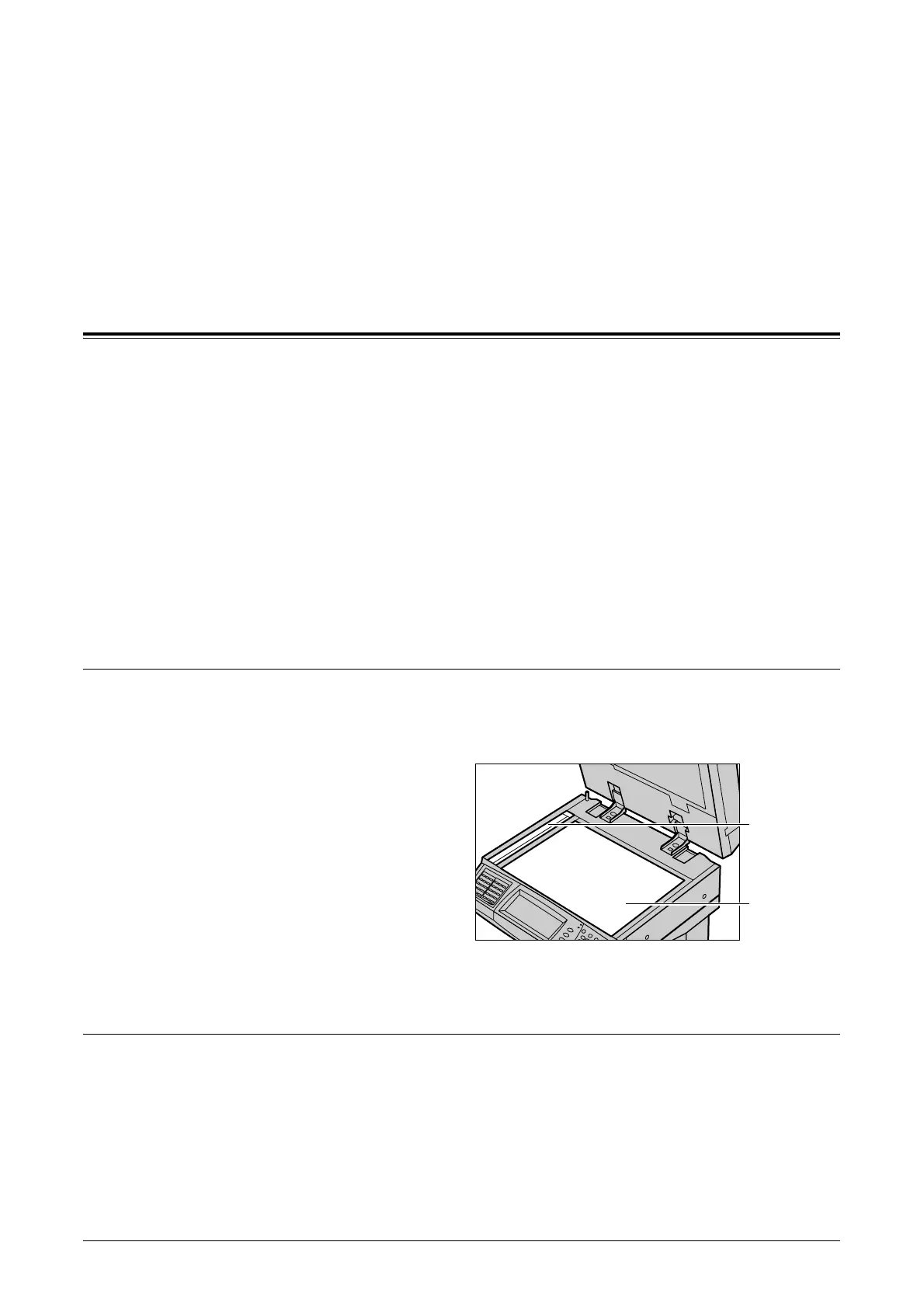

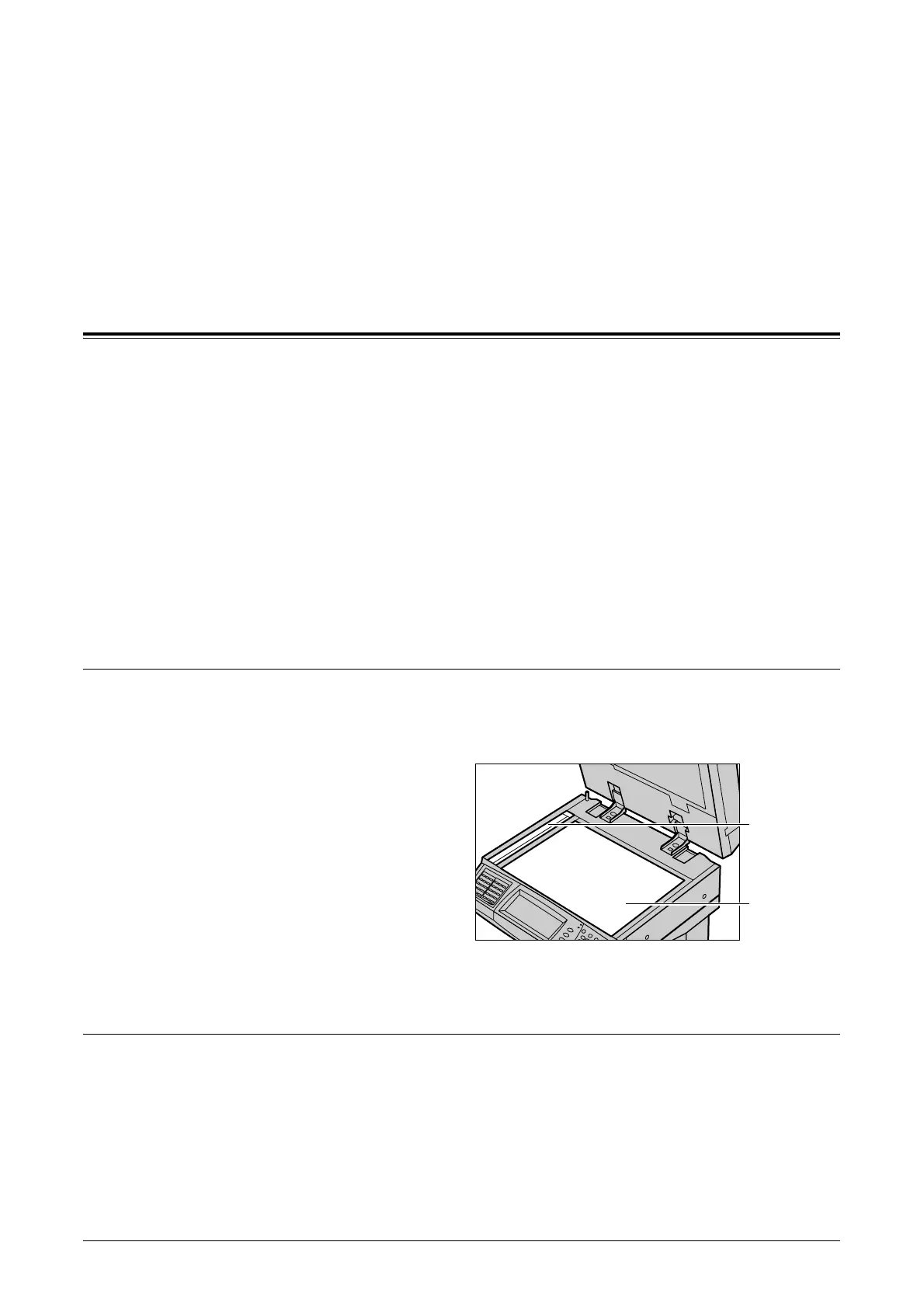

The Document Glass and Constant Velocity Transport Glass

To ensure optimum print quality at all times, clean the document glass and constant

velocity transport glass monthly, or more often if needed. This helps avoid streaks,

smears and other marks on the printed output.

1. To clean the glass areas, use a

lint-free cloth, lightly moistened

with water.

2. Use a soft cloth moistened with

water to clean the white tabs,

located on the underside of the

document glass cover and in the

document feeder, to remove dry

ink smudges and other marks.

3. Wipe the wet surface with a dry, clean cloth.

The Control Panel and Touch Screen

Regular cleaning keeps the touch screen and control panel free from dust and dirt. To

remove finger prints and smudges, clean the control panel and touch screen with a soft,

lint-free cloth, slightly moistened with water.

NOTE: The machine should be switched off before cleaning the control panel to

prevent unintended operation.

Document glass

Constant velocity

transport glass

Loading...

Loading...