11.5

Section 11

Reassembly

11

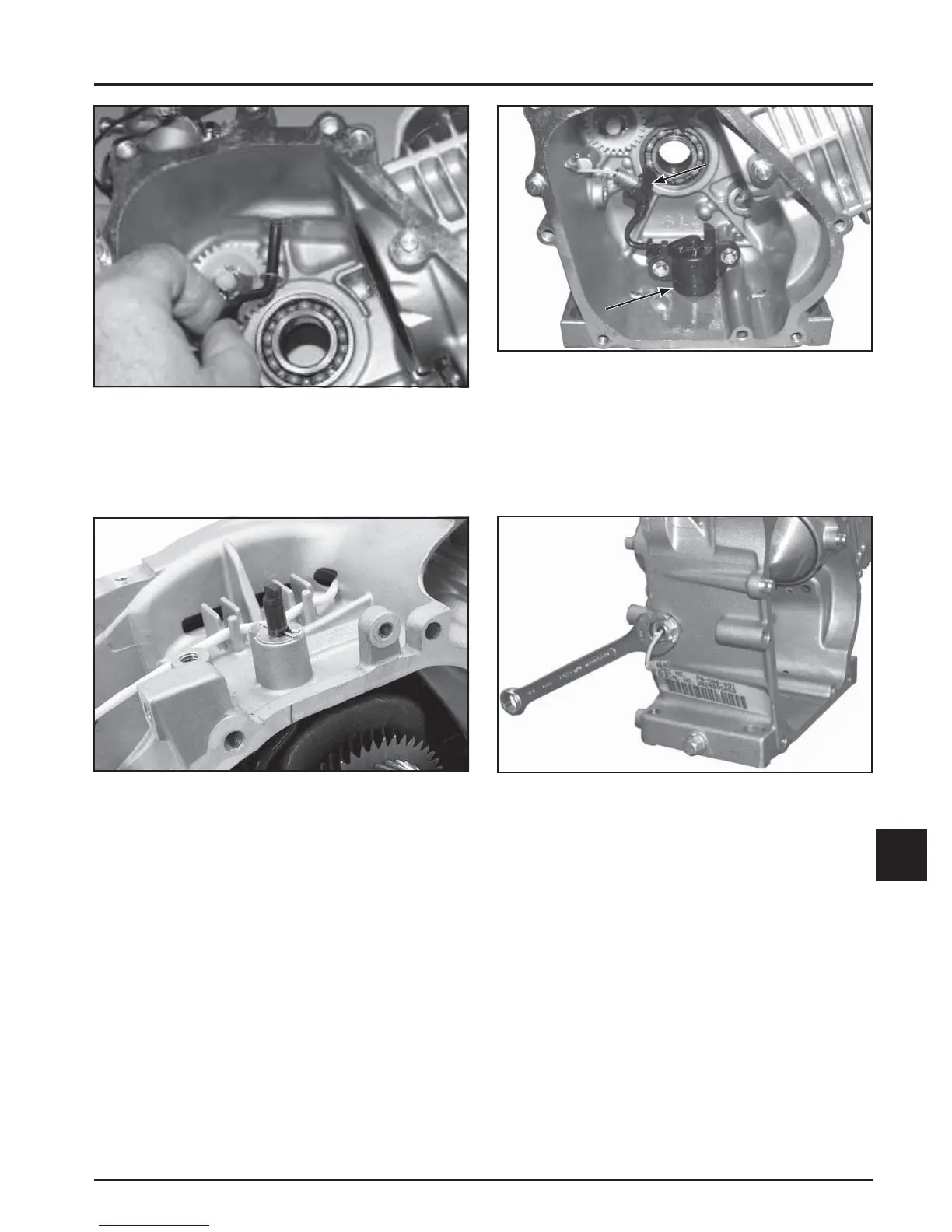

Figure 11-18. Oil Sentry™ Float Switch Mounting.

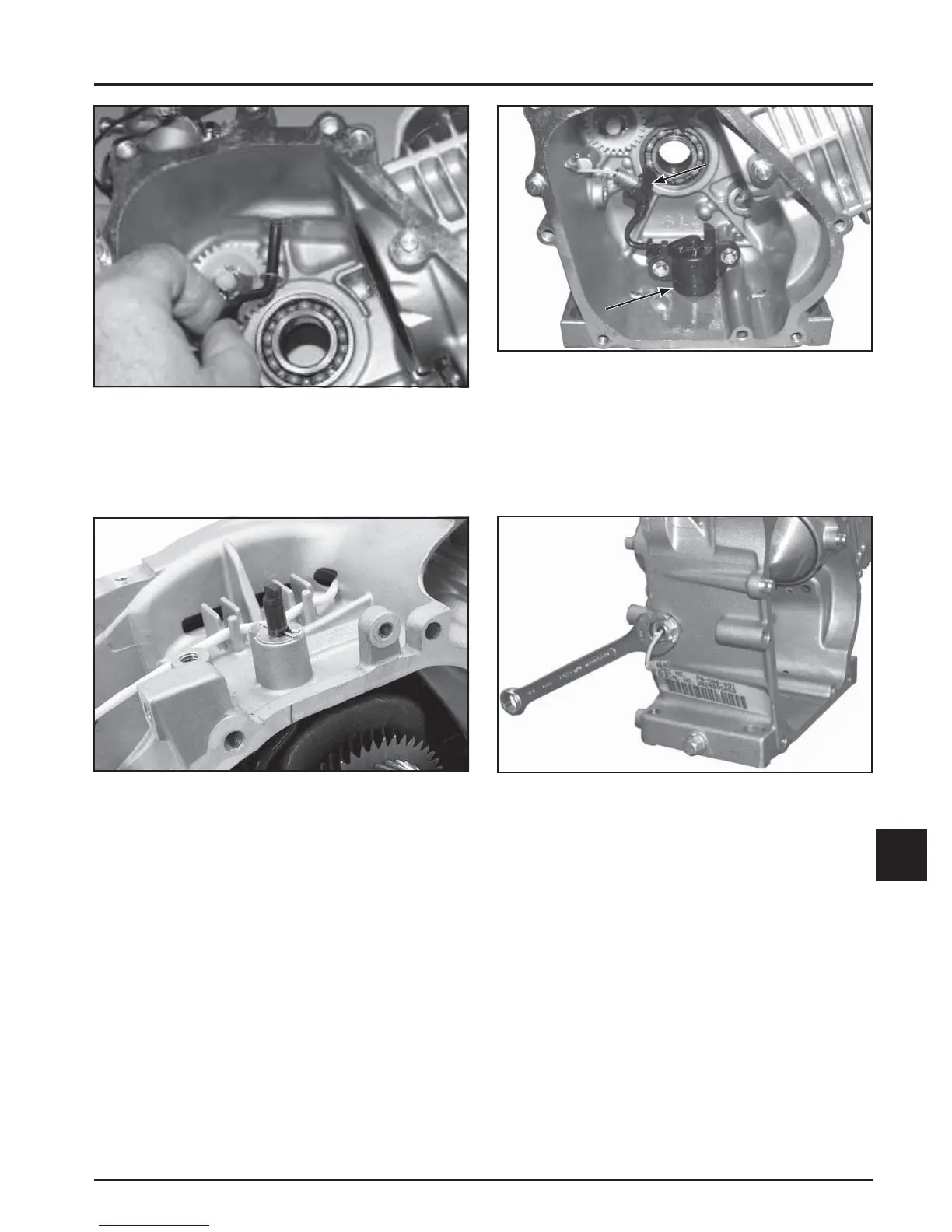

2. Route the wire lead grommet assembly through

the cranksha housing. See Figure 11-18.

3. Install the nut on the grommet assembly external

stud and torque to 10 N·m (89 in. lb.). See Figure

11-19.

Grommet

Assembly

Oil Sentry

TM

Float Switch

Figure 11-19. Oil Sentry™ Wire Lead Grommet

Mounting.

Install Crankshaft

1. Carefully slide the fl ywheel end of the cranksha

through the main ball bearing and seal. See

Figure 11-20.

Figure 11-16. Installing Governor Shaft.

8. Install the second fl at washer onto the sha .

Position the sha so the fl at index end of the sha

faces to the le (9 o'clock position) and insert the

hitch pin from the PTO side. See Figure 11-17.

Figure 11-17. Installing Thrust Washer and Hitch

Pin.

Install Oil Sentry™ System

1. Mount the Oil Sentry™ fl oat switch into the

crankcase housing using two M6x18 hex fl ange

screws and torque to 8 N·m (71 in. lb.). See

Figure 11-18.

Loading...

Loading...