10.9

Section 10

Inspection and Reconditioning

10

Valve Seat Inserts

Hardened steel alloy intake and exhaust valve seat

inserts are press-fi ed into the cylinder head. The

inserts are not replaceable but can be reconditioned if

not too badly pi ed or distorted. If cracked or badly

warped, the cylinder head should be replaced.

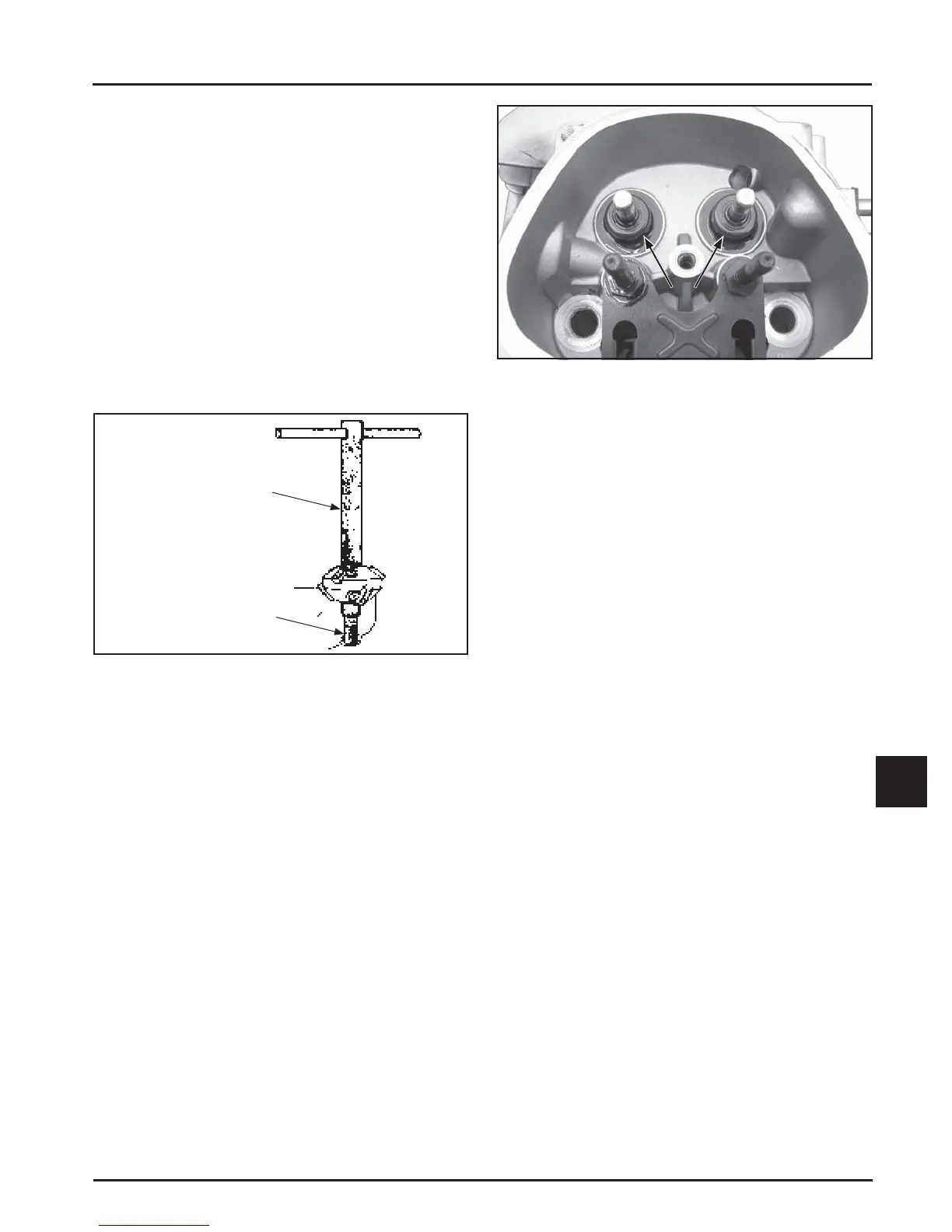

Recondition the valve seat inserts following the

instructions provided with the valve seat cu er

being used. A typical cu er is shown in Figure 10-10.

Cu ing the proper valve face angle, as specifi ed in the

Valve Specifi cation table and the proper valve seat

angle (89.5°-90°) will achieve the desired 0° (1° full

cut) interference angle where the maximum pressure

occurs on the outside diameters of the valve face and

seat.

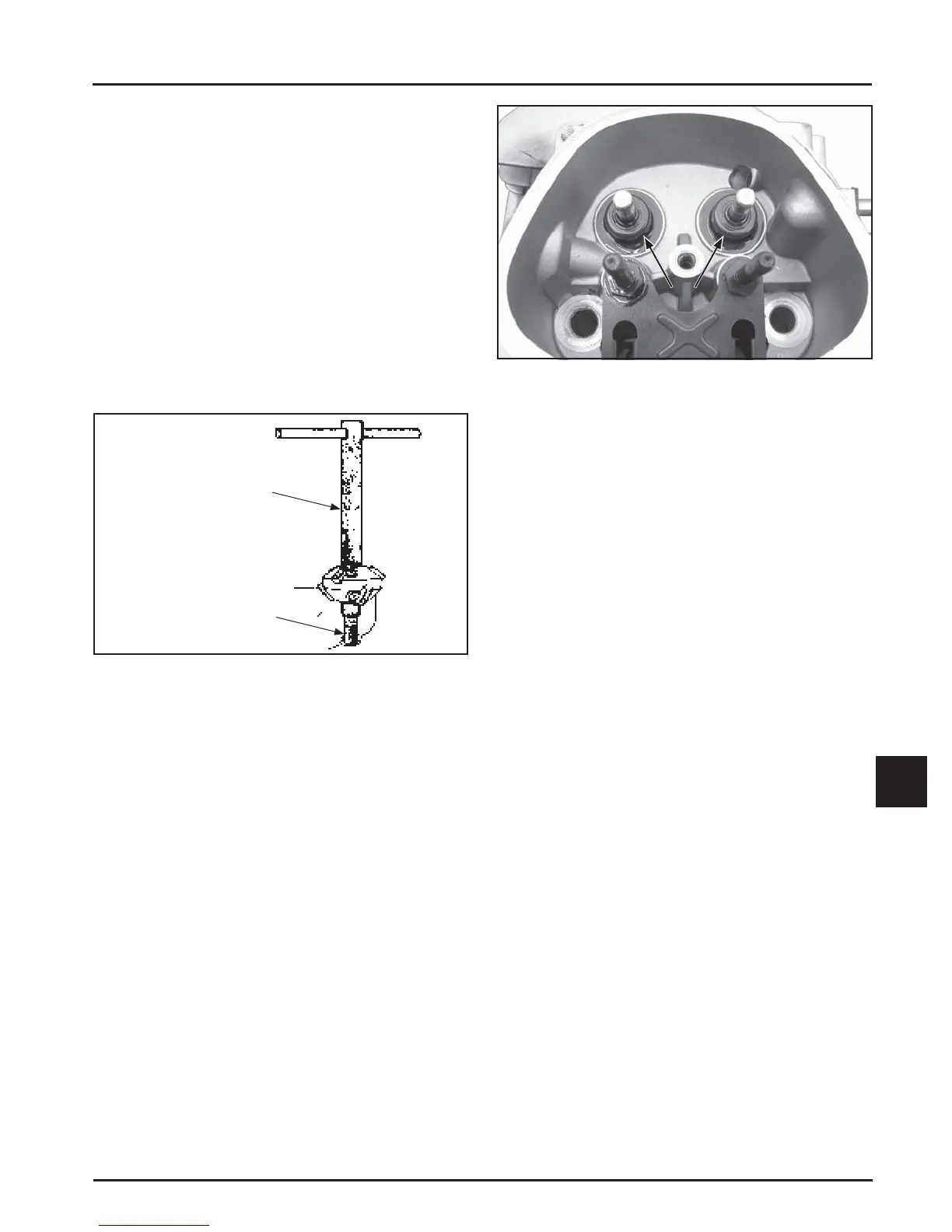

Figure 10-11. Valve Stem Seals.

Always use new seals when the valves are removed

from the cylinder head. The seals should also be

replaced if deteriorated or damaged in any way.

Never reuse old seals.

Pistons and Rings

Inspection

Scuffi ng and scoring of pistons and cylinder walls

occurs when internal engine temperatures approach

the welding point of the piston. Temperatures high

enough to do this are created by friction, which is

usually a ributed to improper lubrication and/or

overheating of the engine.

Normally, very li le wear takes place in the piston

boss-piston pin area. If the original piston and

connecting rod can be reused a er new rings are

installed, the original pin can also be reused but new

piston pin retainers are required. The piston pin is

included as part of the piston assembly – if the pin

boss in the piston or the pin are worn or damaged, a

new piston assembly is required.

Ring failure is usually indicated by excessive oil

consumption and blue exhaust smoke. When rings

fail, oil is allowed to enter the combustion chamber

where it is burned along with the fuel. High oil

consumption can also occur when the piston ring

end gap is incorrect because the ring cannot properly

conform to the cylinder wall under this condition. Oil

control is also lost when ring gaps are not staggered

during installation.

When cylinder temperatures get too high, lacquer and

varnish collect on pistons causing rings to stick, which

results in rapid wear. A worn ring usually takes on a

shiny or bright appearance.

Valve Seat Cutter

Pilot

Figure 10-10. Typical Valve Seat Cutter.

Lapping Valves

Reground or new valves must be lapped in, to provide

fi t. Use a hand valve grinder with suction cup for

fi nal lapping. Lightly coat valve face with fi ne grade

of grinding compound, then rotate valve on seat with

grinder. Continue grinding until smooth surface is

obtained on seat and on valve face. Thoroughly clean

cylinder head in soap and hot water to remove all

traces of grinding compound. A er drying cylinder

head, apply a light coating of SAE 10 oil to prevent

rusting.

Valve Stem Seals

These engines use valve stem seals on the intake and

exhaust valves. See Figure 10-11.

Valve Stem

Seals

Loading...

Loading...