11.7

Section 11

Reassembly

11

Figure 11-24. Installing Piston Using a Ring

Compressor.

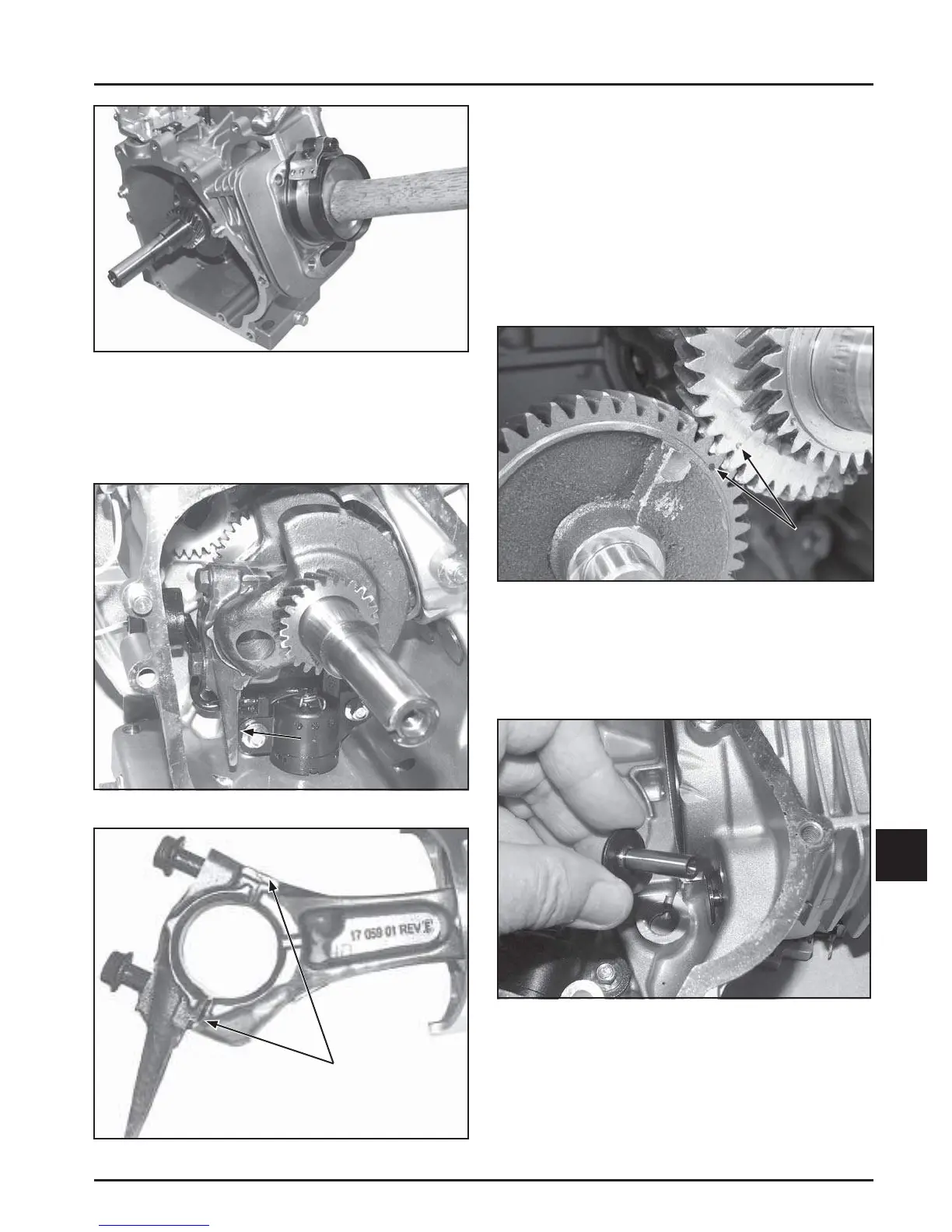

6. Install the connecting rod cap to the connecting

rod so the dipper is down, and the match marks

are aligned. See Figures 11-25 and 11-26.

Figure 11-25. Rod Dipper Orientation.

Dipper

Orientation

Match Marks

7. Torque both screws in increments to:

CH270 12 N·m (106 in. lb.)

CH395, CH440 20 N·m (177 in. lb.)

Install Balance Shaft (If Equipped)

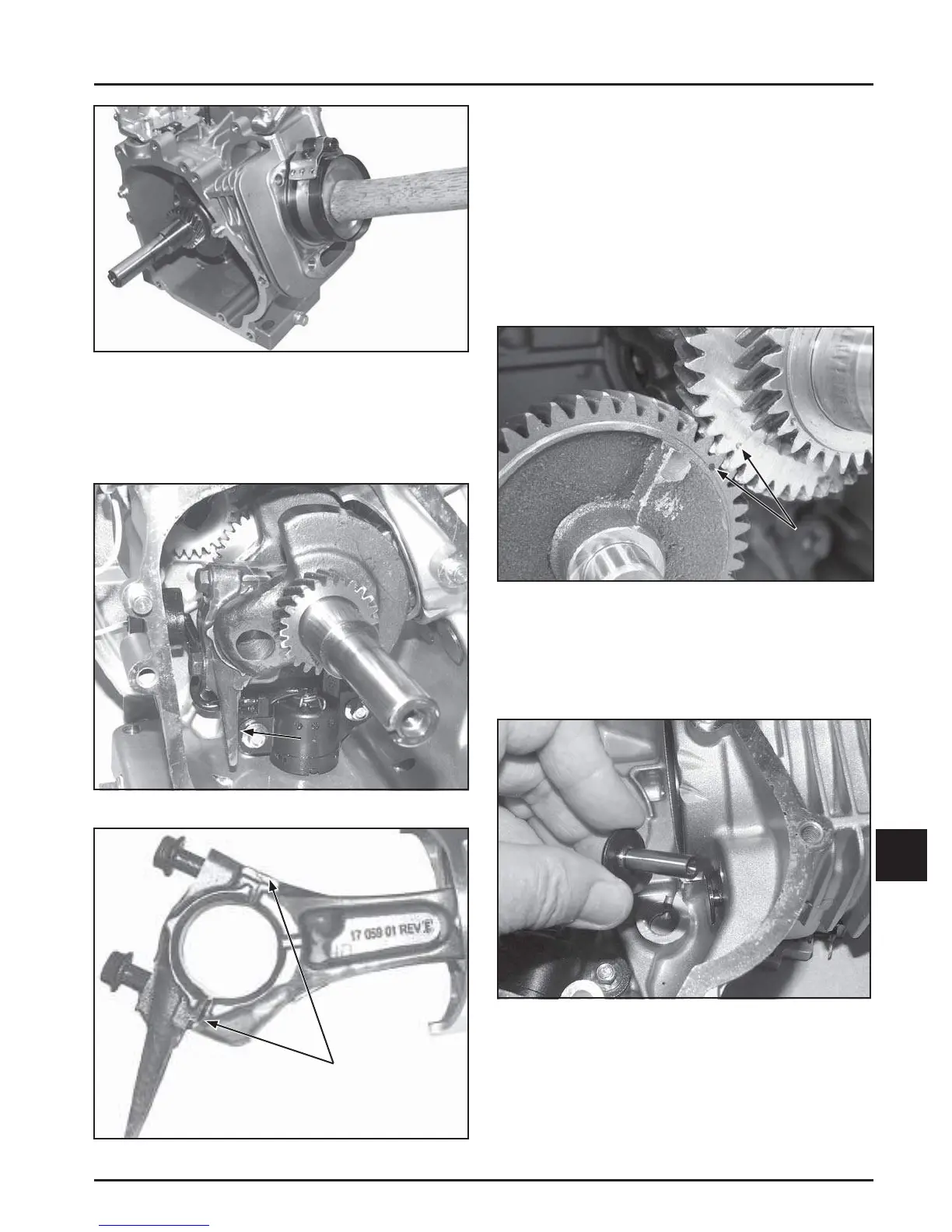

1. Position the cranksha so the timing mark on the

larger crankgear is in the 8 o'clock position.

2. Install the balance sha , aligning the timing mark

with the timing mark on the larger crankgear. See

Figure 11-27.

Figure 11-27. Aligning Timing Marks.

Install Valve Tappets and Camshaft

1. Lubricate the face and stem of each tappet with

engine oil. Install each into their respective bores.

See Figure 11-28.

Figure 11-28. Tappet Installation.

2. Lubricate the camsha bearing surfaces and

cam lobes as well as the camsha bore in the

crankcase with engine oil.

Timing

Marks

Figure 11-26. Connecting Rod Match Marks.

Loading...

Loading...