10.11

Section 10

Inspection and Reconditioning

10

Replacement pistons are available in STD bore size,

and 0.25 mm (0.010 in.) oversize. Replacement pistons

include new piston ring sets and new piston pins.

Replacement ring sets are also available separately for

STD, and 0.25 mm (0.010 in.) oversize pistons. Always

use new piston rings when installing pistons. Never

use old rings.

Some important points to remember when servicing

piston rings:

1. The cylinder bore must be de-glazed before

service ring sets are used.

2. If the cylinder bore does not need re-boring and

if the old piston is within wear limits and free

of score or scuff marks, the old piston may be

reused.

3. Remove the old rings and clean up the grooves.

Never reuse old rings.

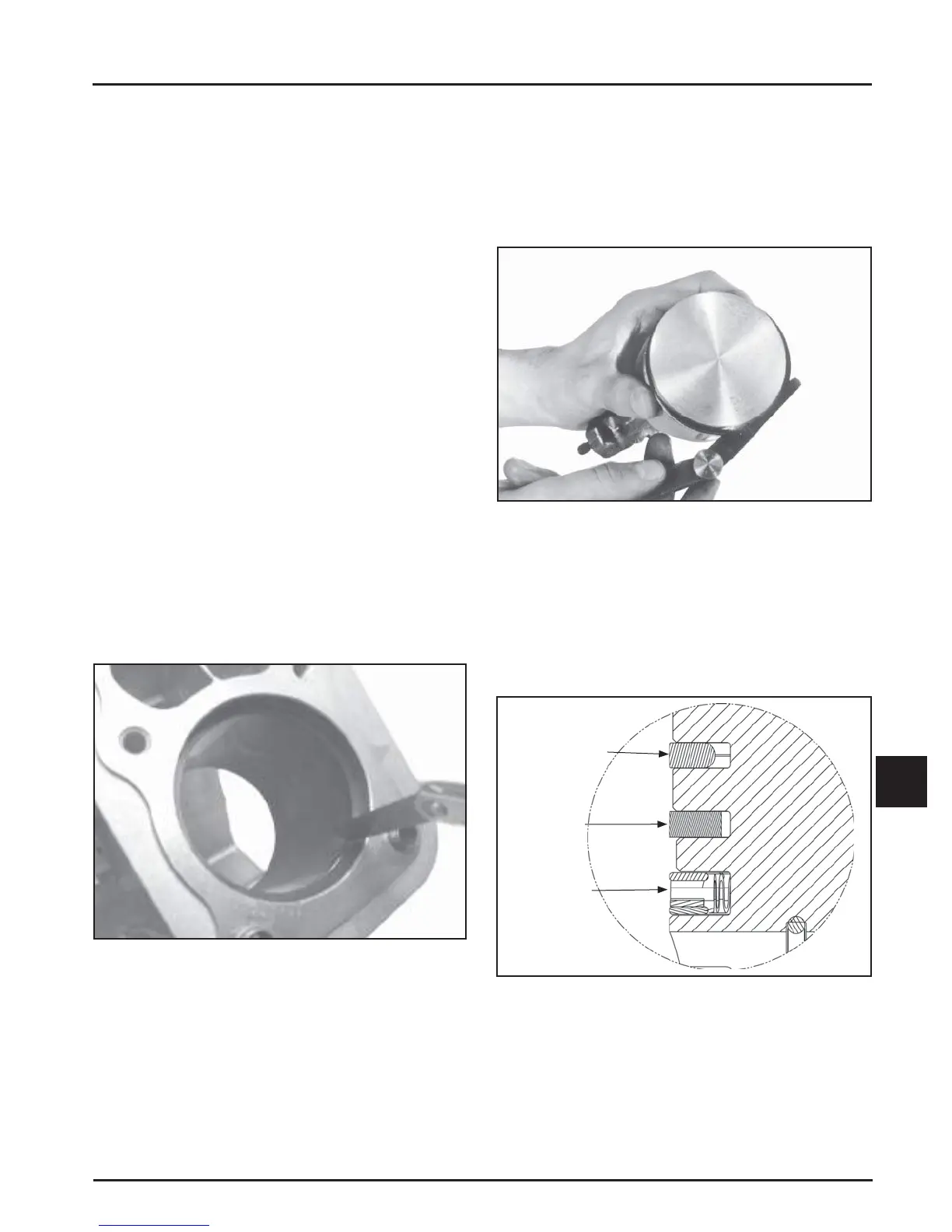

4. Before installing the new rings on the piston,

place the top two rings, each in turn, in its

running area in the cylinder bore and check the

end gap. See Figure 10-13. Compare the ring gap

to the measurements in Section 1, Specifi cations

and Tolerances.

Figure 10-13. Measuring Piston Ring End Gap.

5. A er installing the new compression (top and

middle) rings on the piston, check the piston-

to-ring side clearance. Compare the clearance to

specifi cations listed in Section 1, Specifi cations

and Tolerances. If the side clearance is greater

than specifi ed, a new piston must be used. See

Figure 10-14.

Figure 10-14. Measuring Piston Ring Side

Clearance.

Install New Piston Rings

To install new piston rings, proceed as follows:

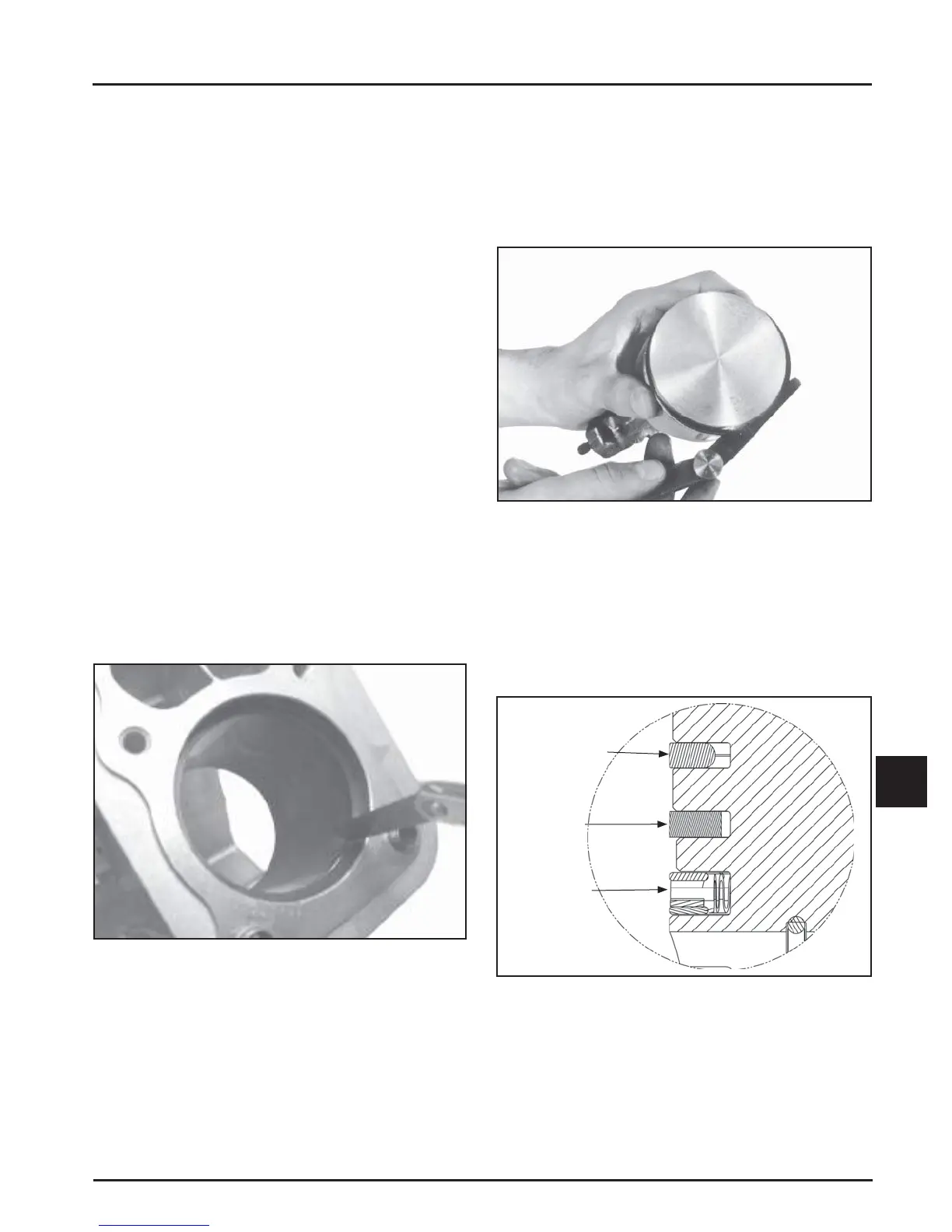

NOTE: Rings must be installed correctly. Install the

bo om (oil control) ring fi rst and the top

compression ring last. See Figure 10-15.

2nd Ring

Top Ring

Oil Ring

Figure 10-15. Piston Ring Positions.

Use a piston ring expander to install rings. See

Figure 10-16.

Loading...

Loading...