8.12

Section 8

Electrical System and Components

Starter Removal and Installation

Refer to the Disassembly and Reassembly sections

for starter removal and installation procedures.

Operation

When power is applied to the starter, the armature

rotates. As the armature rotates, the drive pinion

moves out on the splined drive sha and into mesh

with the fl ywheel ring gear. When the pinion reaches

the end of the drive sha , it rotates the fl ywheel

and cranks the engine. When the engine starts, the

fl ywheel rotates faster than the starter armature

and drive pinion. This moves the drive pinion out

of mesh with the ring gear and into the retracted

position. When power is removed from the starter, the

armature stops rotating and the drive pinion is held in

the retracted position by the anti-dri spring.

Starter Drive Service

Every 200 hours of operation (or annually, whichever

occurs fi rst), clean and lubricate the geartrain. If the

gears are worn, or have chipped or broken teeth, the

starter must be replaced.

It is not necessary to completely dissemble the starter

to service the geartrain. Service the starter as follows:

1. Remove the starter from the engine.

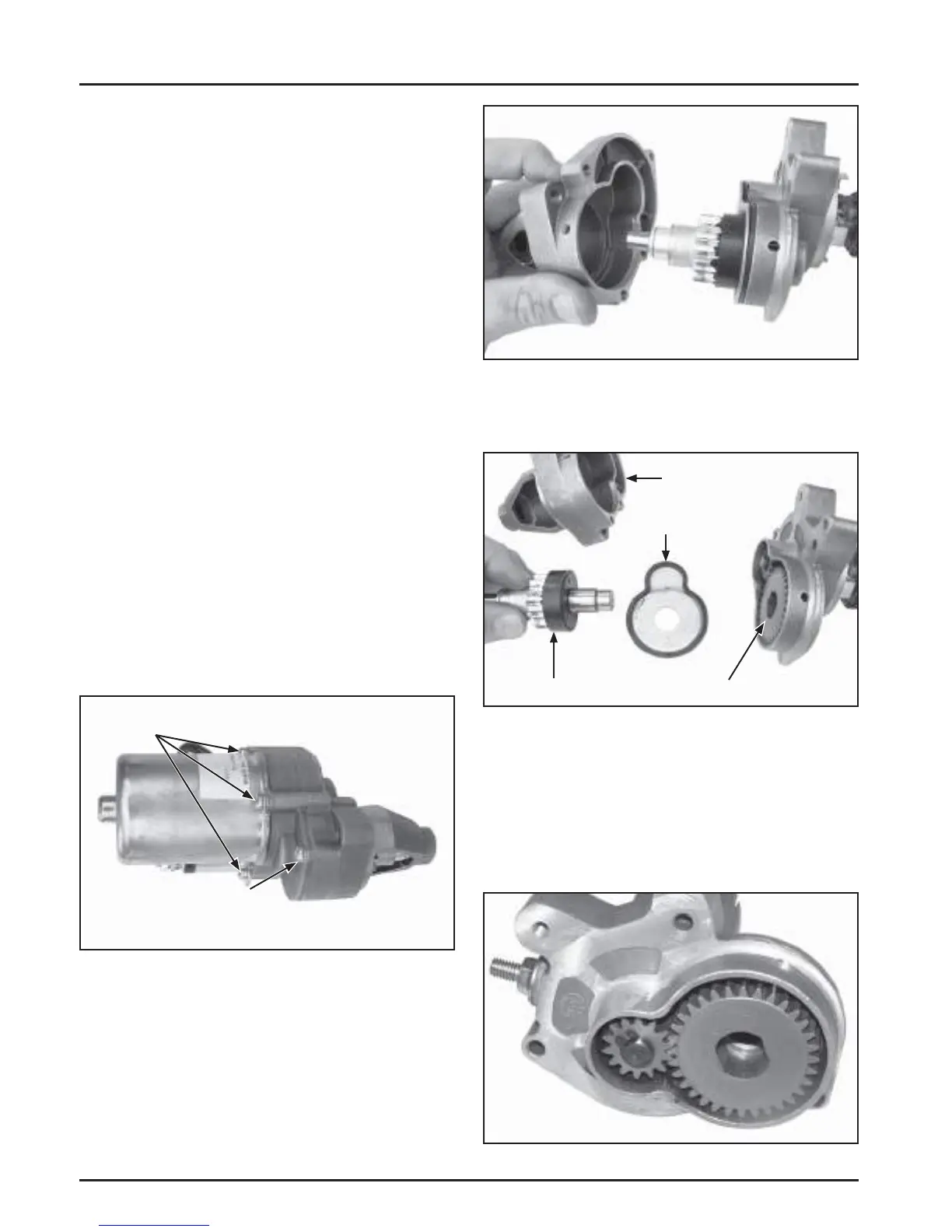

2. Remove the housing screws and the drive end

cap screw. See Figure 8-11.

Figure 8-11. Remove Housing and Drive End Cap

Screws.

3. Remove the drive end cap. The drive pinion will

either remain in the geartrain or come out with

the drive end cap. See Figure 8-12.

Figure 8-12. Remove Drive End Cap.

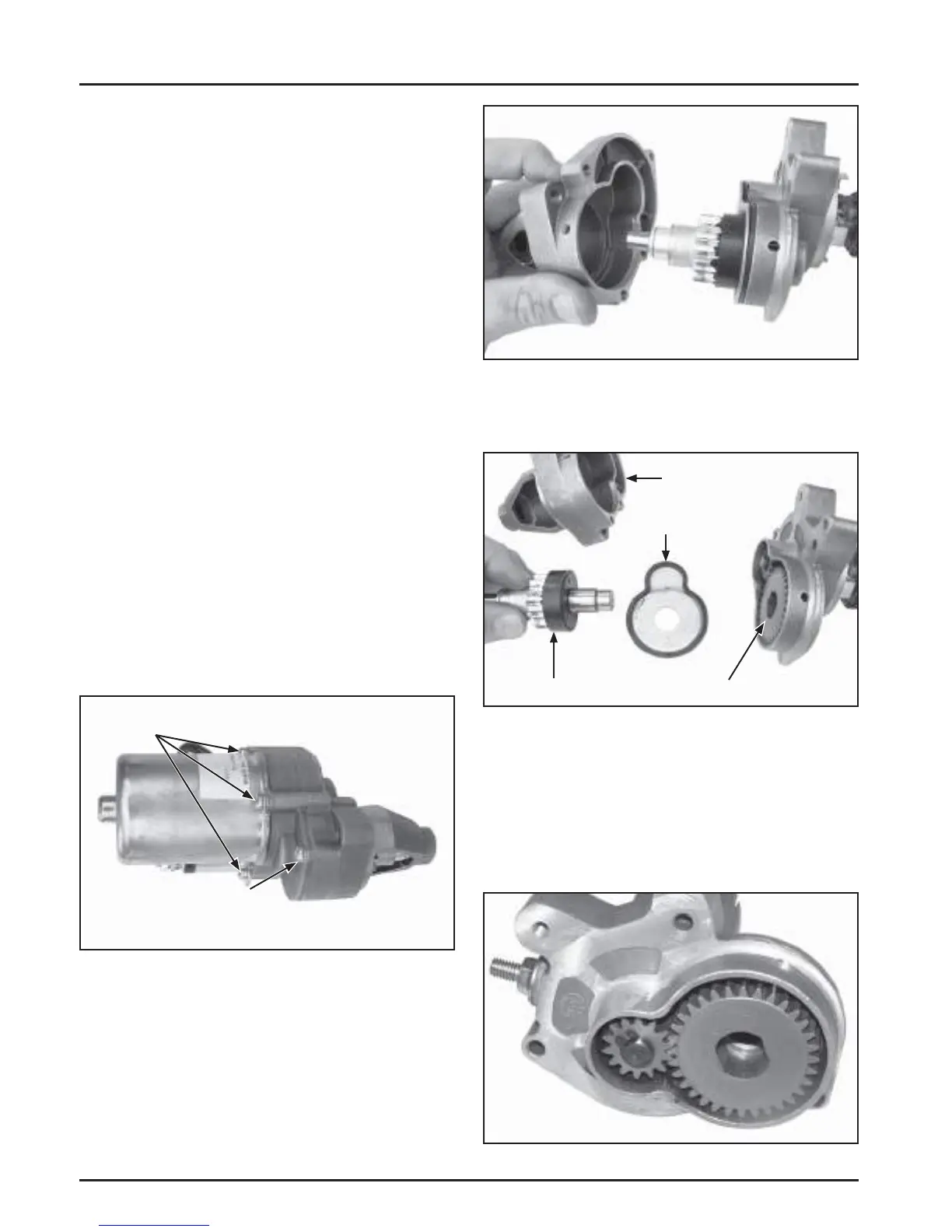

4. Remove the drive pinion and dust cover,

exposing the geartrain. See Figure 8-13.

Figure 8-13. Disassembled Drive Components.

5. Inspect the gears for damage or wear.

6. Clean the gears as required.

7. Apply a small amount of Kohler electric starter

drive lubricant, (see Section 2) to the geartrain.

See Figure 8-14.

Figure 8-14. Lubricate Geartrain.

Housing

Screws

Drive End

Cap Screw

Drive Pinion

Drive End Cap

Dust Cover

Geartrain

Loading...

Loading...