11.9

Section 11

Reassembly

11

Clean Bore and

Shaft Surfaces

Figure 11-34. Install Bracket and Torque Screw.

Install Flywheel

WARNING: Damaging Crankshaft and

Flywheel Can Cause Personal Injury!

Using improper procedures to install the fl ywheel can crack

or damage the cranksha and/or fl ywheel. This not only

causes extensive engine damage, but can also cause personal

injury, since broken fragments could be thrown from the

engine. Always observe and use the following precautions

and procedures when installing the fl ywheel.

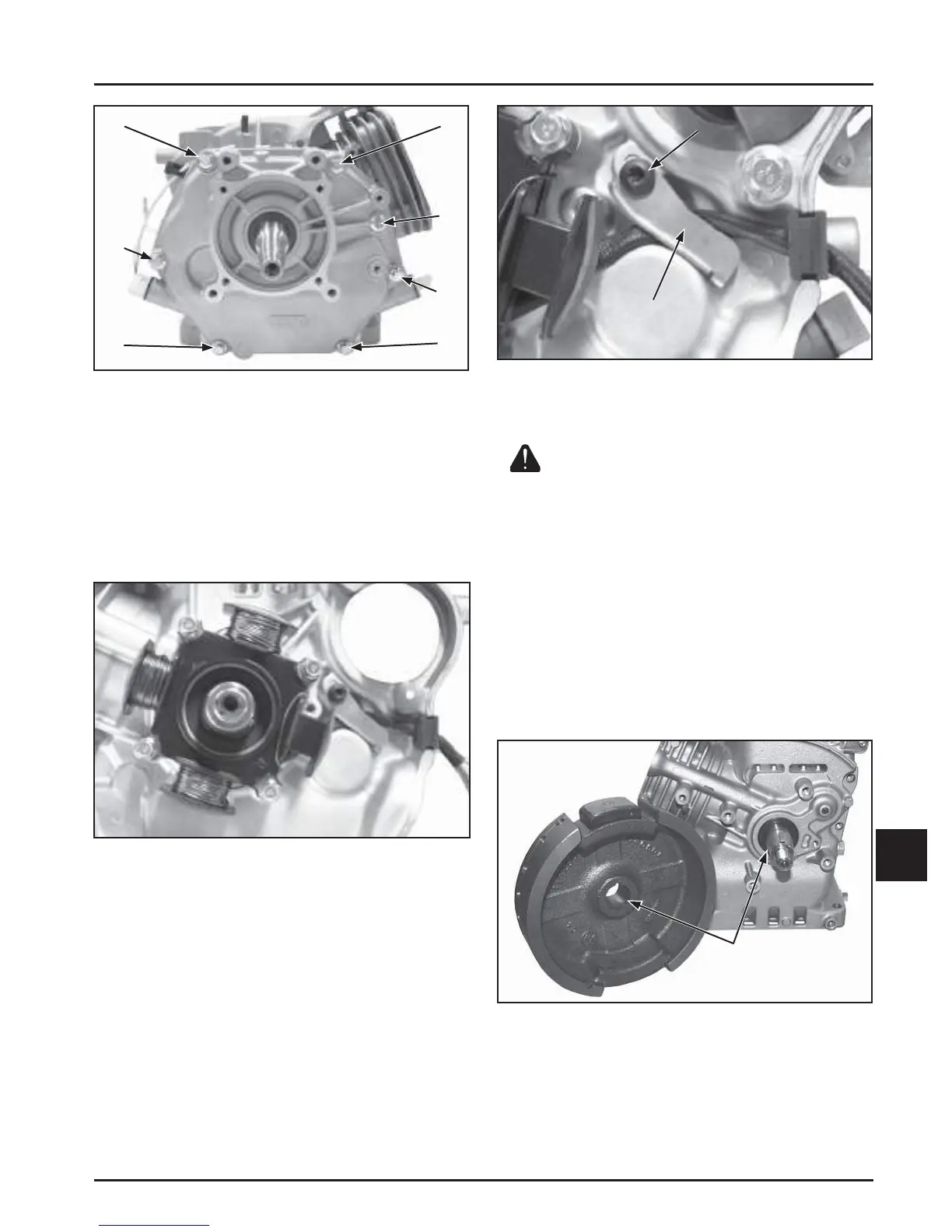

NOTE: Before installing the fl ywheel make sure the

cranksha taper and fl ywheel hub bore are

clean, dry, and completely free of lubricants.

The presence of lubricants can cause over-

stressing and damage when the fl ange nut is

torqued to specifi cation. See Figure 11-35.

Figure 11-35. Clean and Dry Taper of Crankshaft

and Flywheel Bore.

NOTE: In the following step, make sure the fl ywheel

key is installed properly in the keyway. The

fl ywheel can become cracked or damaged if

the key is not installed properly.

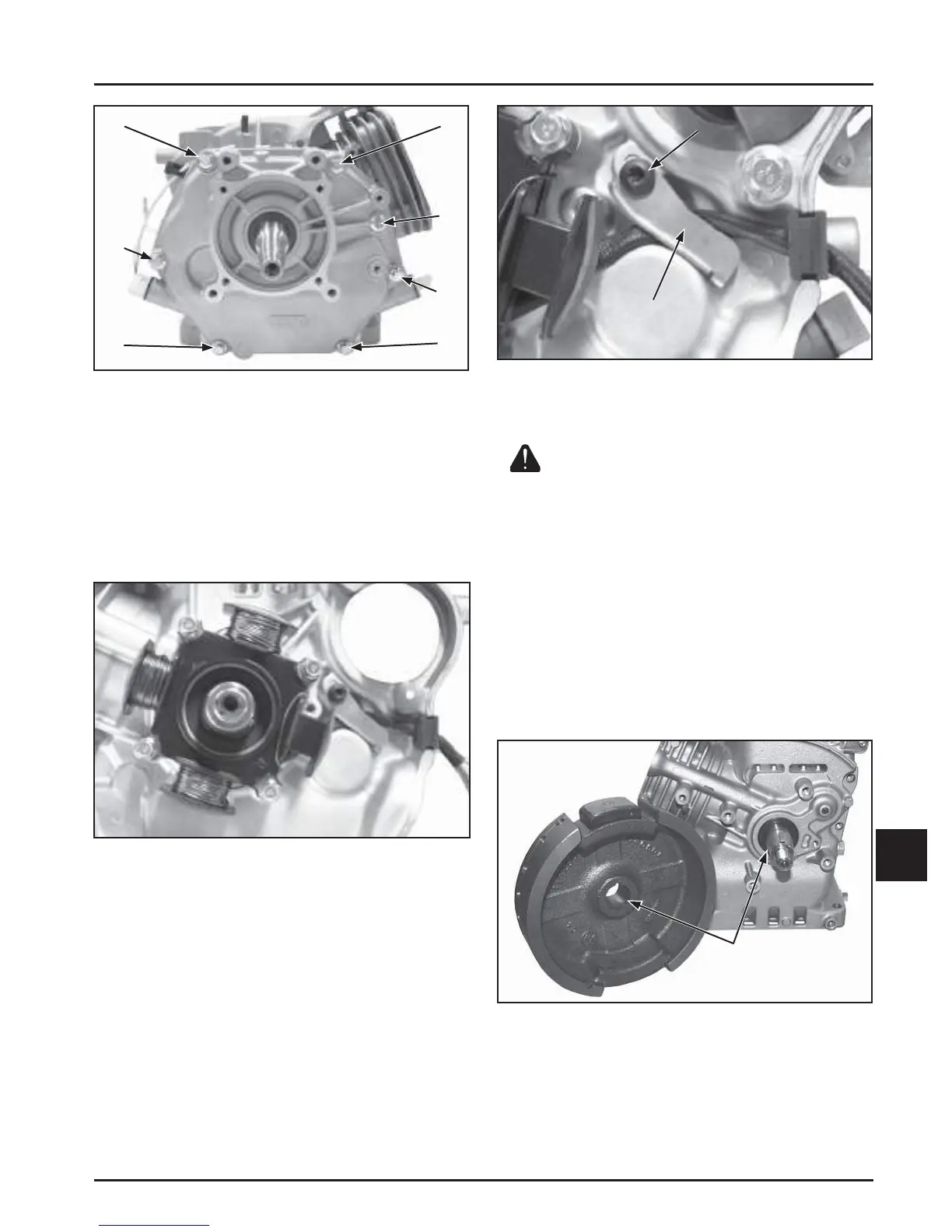

Figure 11-32. CH395, CH440 Closure Plate Torque

Sequence.

Install Stator (If Equipped)

1. Position the stator aligning the mounting holes so

the leads are in the 3 o'clock position.

2. Install and torque the four hex fl ange screws to

10 N·m (89 in. lb.) in the sequence of 1, 2, 3, 4 and

then torque 1 again. See Figure 11-33.

Figure 11-33. Stator Screws Torque Sequence.

3. Route the stator leads along the crankcase and

out the notch on the side.

4. Position the bracket over the stator leads

and install and torque the screw to 10 N·m

(89 in. lb.). See Figure 11-34.

1

2

4

6

7

3

5

1&5

2

3

4

Bracket

Torque

Screw

Loading...

Loading...