10.12

Section 10

Inspection and Reconditioning

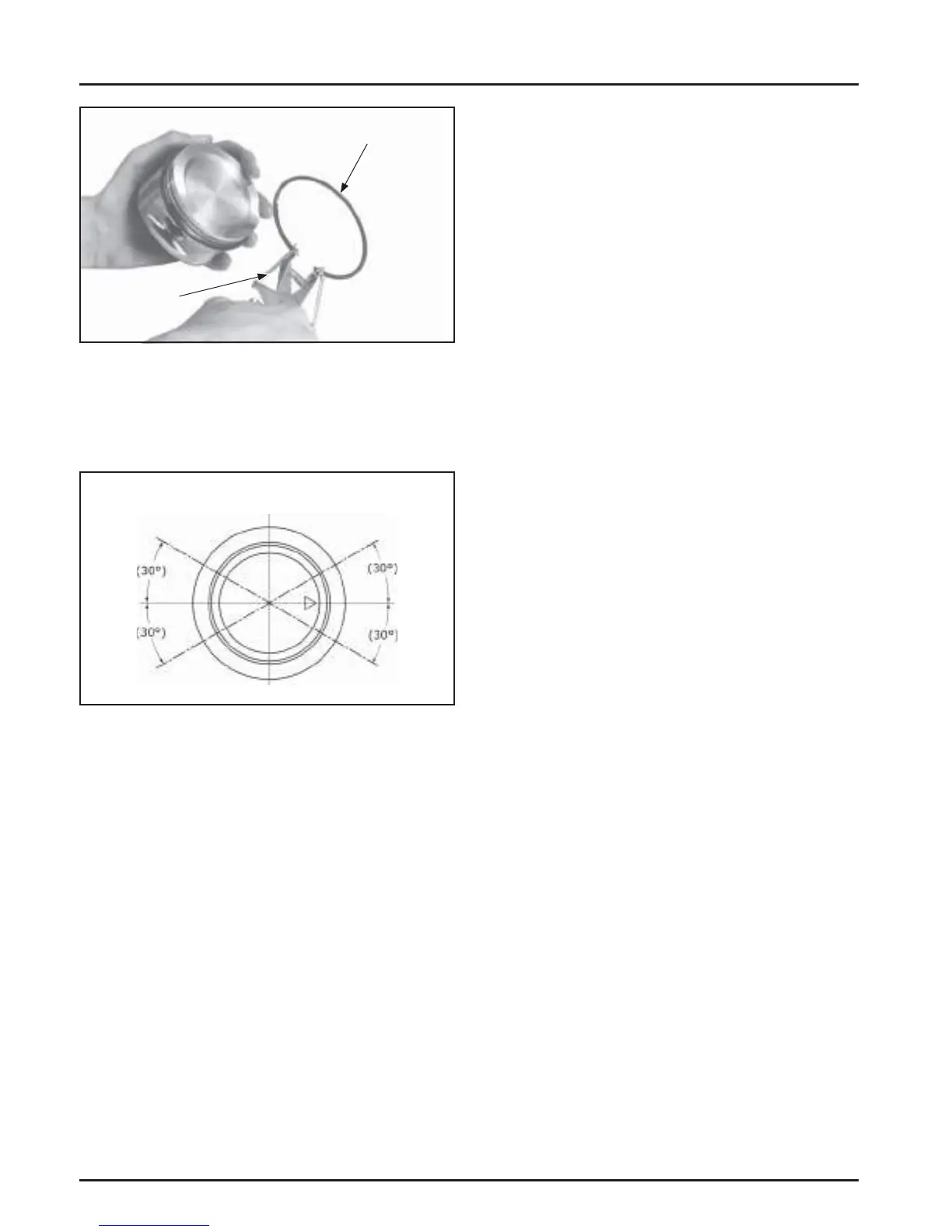

Figure 10-16. Piston Ring Expander.

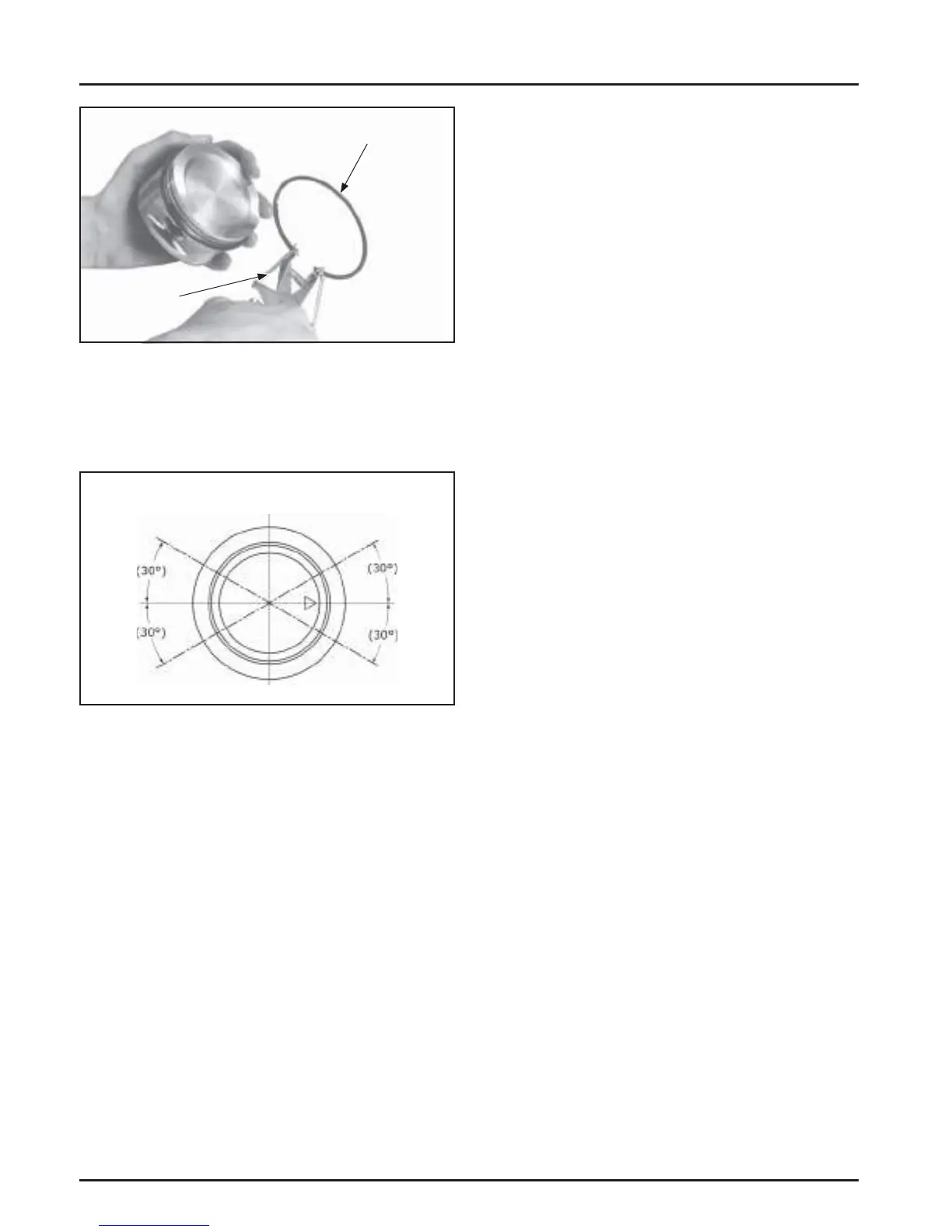

1. Oil Control Ring (Bo om Groove): Install the

expander and then the rails. Make sure the ends

of the expander are not overlapped. See Figure

10-17.

Oil Ring

Expander Gap

Top Ring

Gap

2nd Ring

Gap

Bottom Oil

Rail Gap

Top Oil

Rail Gap

Figure 10-17. Piston Ring Orientation.

2. Middle Compression Ring (Center Groove):

Install the center ring using a piston ring

expander tool. Make sure the identifi cation mark

is up or the colored dye stripe (if contained) is to

the le of the end gap. See Figure 10-17.

3. Top Compression Ring (Top Groove): Install the

top ring using a piston ring expander tool. Make

sure the identifi cation mark is up or the colored

dye stripe (if contained) is to the le of the end

gap. See Figure 10-17.

Connecting Rods

Off set, stepped-cap connecting rods are used in all

these engines.

Inspection and Service

Check the bearing area (big end) for excessive wear,

score marks, running and side clearances (see Section

1, Specifi cations and Tolerances). Replace the rod and

cap if scored or excessively worn.

Piston Ring

Piston Ring

Expander

Service replacement connecting rods are available

in STD size and 0.25 mm (0.010 in.) undersize.

The 0.25 mm (0.010 in.) undersized rods have an

identifi cation marking on the lower end of the

rod shank. Always refer to the appropriate parts

information to ensure that correct replacements are

used.

Closure Plate Assembly

Inspection

Inspect the main bearing surface for wear or damage.

Refer to Section 1, Specifi cations and Tolerances.

Replace the closure plate if required.

Governor Assembly (Internal)

Inspection

Inspect the governor gear teeth. Replace the gear if it

is worn, chipped, or if any teeth are missing. Inspect

the governor weights. They should move freely in the

governor gear.

Breather Design

The breather system is designed to control the amount

of oil in the head area and still maintain the necessary

vacuum in the crankcase. The system includes an

inner chamber in the valve cover containing a mesh

fi lter, spring steel reed, and retainer.

When the pistons move downward, crankcase gases

move through a passage to the inner chamber. In

turn, air is pushed past the reed to the intake system.

The upward travel of the pistons closes the reed and

creates a low vacuum in the lower crankcase. This

separates the oil from the airfl ow in the mesh fi lter.

Any oil separated through the fi lter drains back into

the crankcase through a small hole in the inner valve

cover.

Loading...

Loading...